Casting device for manufacturing fused silica ceramics

A technology made of fused silica and ceramics, used in clay preparation devices, ceramic molding machines, clay mixing devices, etc., can solve the problems of incompleteness, long production cycle, slow inflow speed, etc., and achieve scientific and reasonable structure, uniform and thorough stirring, Safe and easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

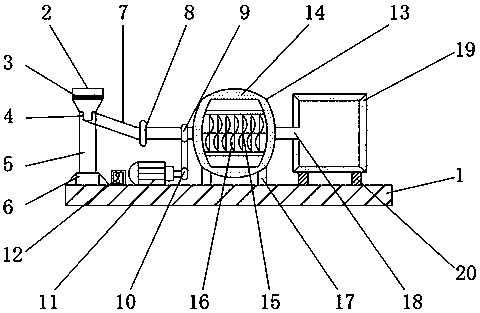

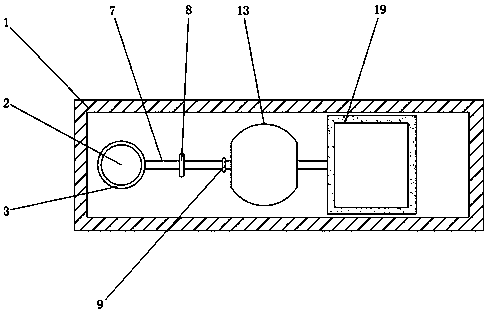

[0016] Example: such as Figure 1-2 As shown, the present invention provides a technical solution: a casting device for making fused silica ceramics, including a bottom support plate 1, a mud inlet 2, a filter screen 3, a concave fixing groove 4, a support vertical rod 5, and a fixing plate 6 , conveying pipe 7, connecting joint 8, transmission belt 9, transmission belt 10, variable speed motor 11, control switch 12, centrifugal chamber 13, constant temperature layer 14, rotating shaft 15, auger blade 16, reinforced support column 17, pouring port 18, Mold frame 19 and support column 20, fixed disk 6 is installed on the left end of bottom support disk 1 top, and support vertical rod 5 is installed above the fixed disk 6, and concave-shaped fixing groove 4 is opened above the support vertical rod 5, and the top of concave-shaped fixing groove 4 A mud inlet 2 is installed, and a delivery pipe 7 is fixedly connected to the right side of the concave fixing groove 4, and a transmis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com