Resistance adjusting mechanism of magnetic control bodybuilding /competition vehicle

A resistance adjustment, racing car technology, applied in the field of fitness equipment, can solve the problems of brake pad wear, distance difference, and affecting the smoothness of the inertial wheel rotation, and achieve the effect of ensuring magnetic resistance and smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

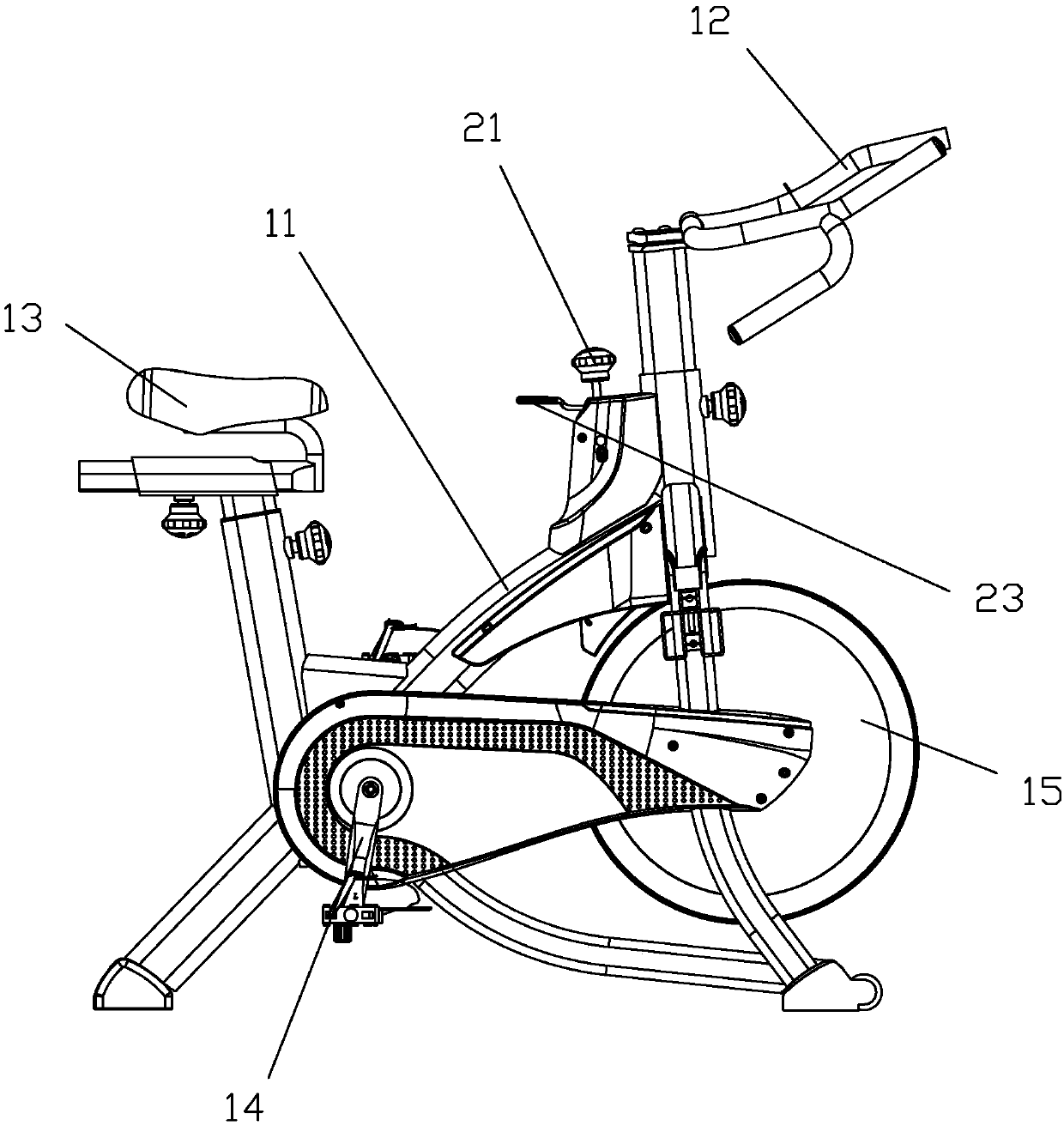

[0030] see figure 1 Described, a kind of magnetically controlled fitness / competition car of the present invention comprises vehicle frame 11, armrest 12, seat cushion 13, pedal wheel mechanism 14 and inertial wheel 15, and armrest 12 and seat cushion 13 are contained on the vehicle frame 11 respectively , pedal wheel mechanism 14 and inertia wheel 15 are also contained respectively on the vehicle frame 11 and are in the position of matching, when pedal wheel mechanism 14 moves, can drive inertia wheel 15 to rotate.

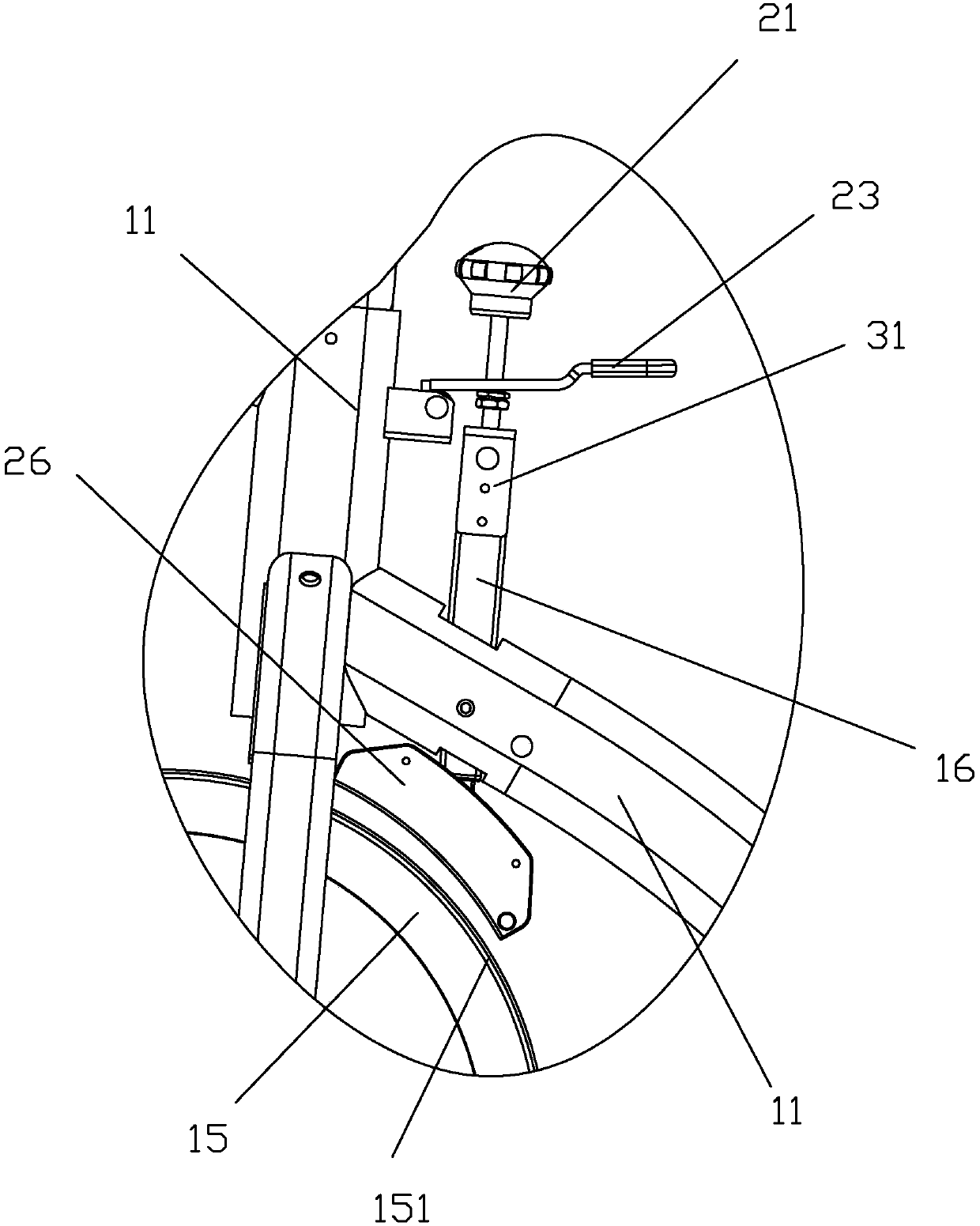

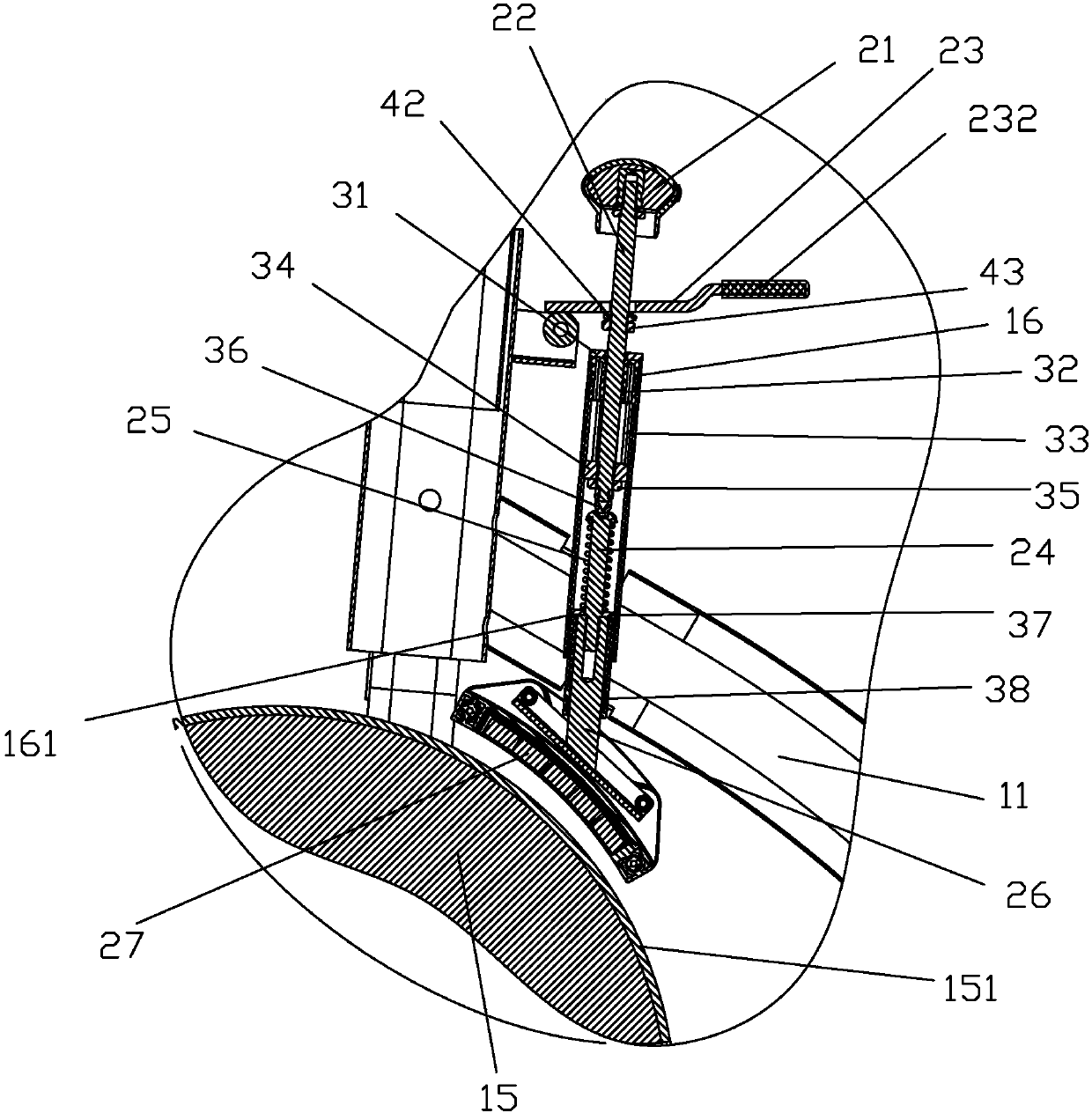

[0031] see Figure 2 to Figure 4 As mentioned above, the resistance adjustment mechanism of a magnetically controlled fitness / racing car of the present invention includes a casing 16, a brake screw 22, a stopper 33, a first nut 34, a bolt 24, a first compression spring 25, and a magnetic plate to fix the frame 26 and magnet block 27; the sleeve 16 is installed at the vehicle frame 11 corresponding to the position of the inertia wheel 15; the first nut 34 can be m...

Embodiment 2

[0050] see Figure 5 As mentioned above, the difference between the magnetically controlled fitness / racing vehicle of the present invention and the first embodiment is that the limiting member 33 is a second compression spring, and the elastic force of the second compression spring is smaller than that of the first compression spring 25 elastic force.

[0051] This design of the present invention is a technical solution adopted in order to improve the comfort of adjustment. When the knob 21 faces in one direction, the brake screw 22 rotates, and the brake screw 22 tends to move downward, while the first nut 34 has The trend of upward movement, because the top of the first nut 34 adopts the second stage clip as the stopper 33, has compressibility, and the elastic force of the second stage clip is less than the elastic force of the first stage clip 25, at this moment, The first nut 34 can move upwards, and when the elastic force increases after the second stage clip is pressed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com