Nerve conduit of magnesium wire and silk compositely woven structure and preparation method of nerve conduit

A nerve guide and magnesium wire technology, applied in tissue regeneration, medical science, prosthesis, etc., can solve the problems of unable to provide a stable mechanical environment for damaged nerves, difficult to control the size and distribution of holes, and insufficient mechanical strength of nerve guides, etc., to achieve Good surface activity and permeability, increase flexibility and bending performance, and promote adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The preparation method of the nerve guide with composite braided structure of magnesium silk and silk comprises the following steps:

[0036] (1) Preparation of the nerve guide middle layer 2, using a vertical spindle braiding machine with a core function to prepare the nerve guide skeleton structure, magnesium wire as the shaft yarn 4, degummed silk as the braiding yarn 5, and composite braiding.

[0037] (2) Preparation of silk fibroin solution: Weigh 30g silkworm raw silk in 12L boiling Na 2 CO 3 (0.02 M) degumming in aqueous solution for 30 minutes, stirring with a glass rod every 10 minutes to ensure the thoroughness of degumming, then rinse with deionized water several times, put the washed silk fibroin fiber in a fume hood overnight Air dry. Weighed 25 g of dried silkworm silk fiber and dissolved it in 100 mL of LiBr (9.3 M) solution, and dissolved it in an oven at 60 °C for 4 hours, shaking slightly every hour to ensure complete dissolution to obtain the first...

Embodiment 1

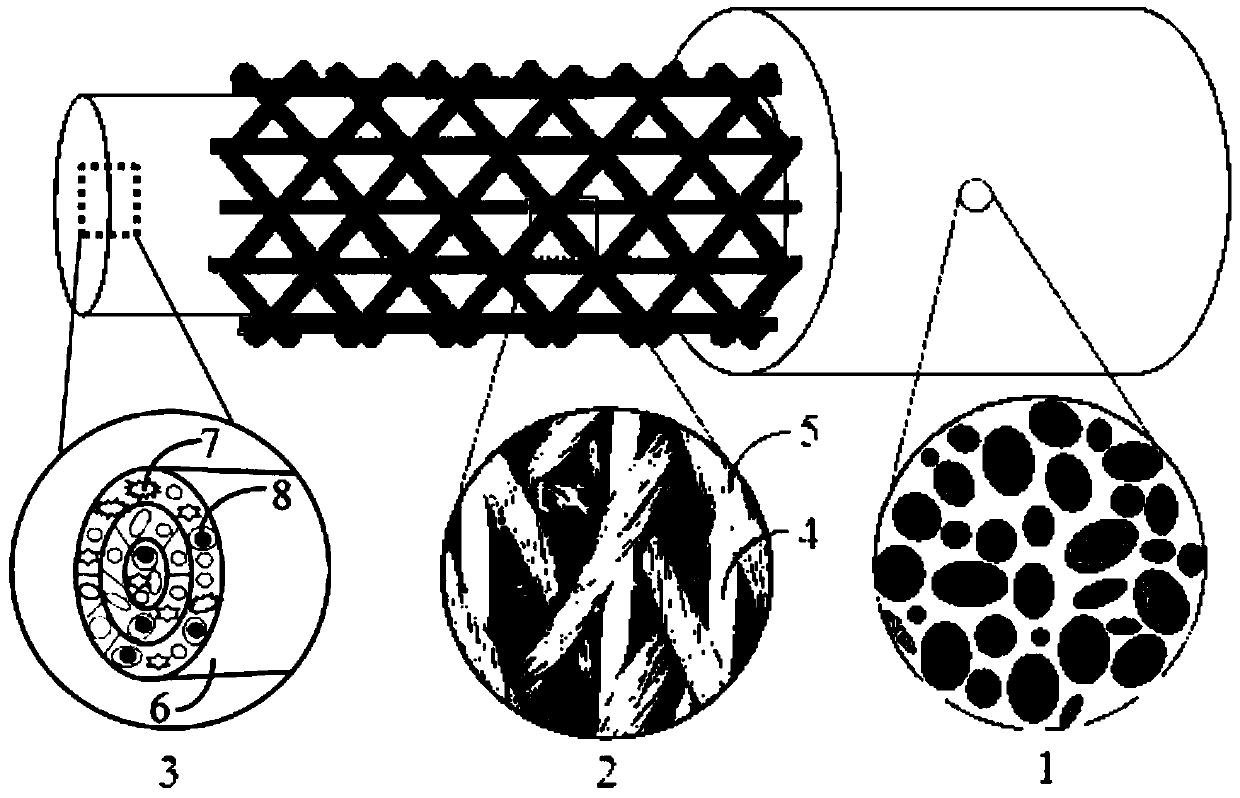

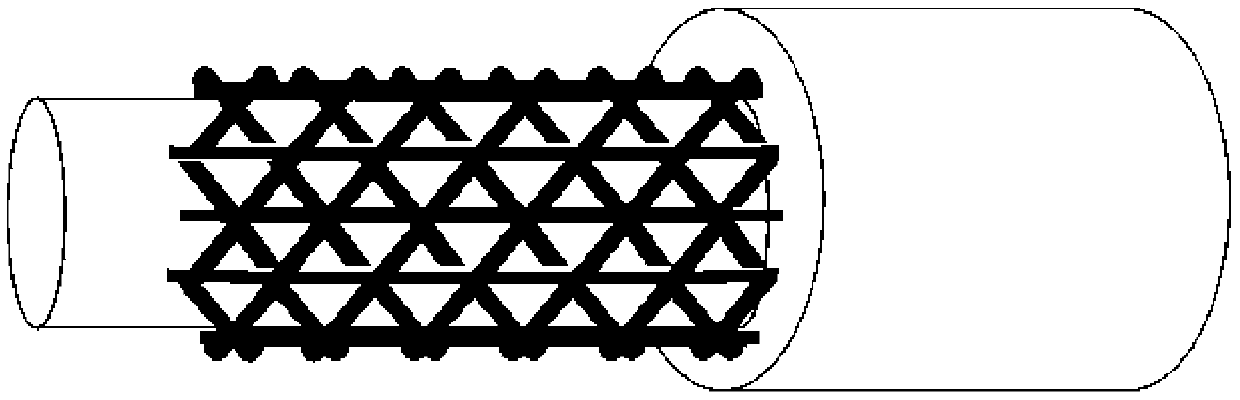

[0045] This implementation case shows a nerve conduit structure and preparation method of a composite braided structure of magnesium silk and silk, such as figure 1 As shown, the nerve guide has three layers, wherein the axis yarn 4 of the nerve guide middle layer 2 is magnesium wire, the braided yarn 5 of the nerve guide middle layer 2 is degummed silk, and the nerve guide outer layer 1 is silk fibroin and chitosan The porous sponge layer made by mixing sugar solution, the mass ratio of silk fibroin and chitosan is 10:1, the concentration of chitosan solution is 3-6 mg / mL, and the concentration of silk fibroin aqueous solution is 5-10% (w / v). The inner layer 3 of the nerve guide is a porous silk gel layer made of an aqueous solution of silk fibroin with a concentration of 5-10% (w / v). The preparation process is as follows:

[0046] (1) Braiding method is used to prepare the middle layer 2 of the nerve conduit: the raw material is 20-100 D degummed silk, magnesium wire with...

Embodiment 2

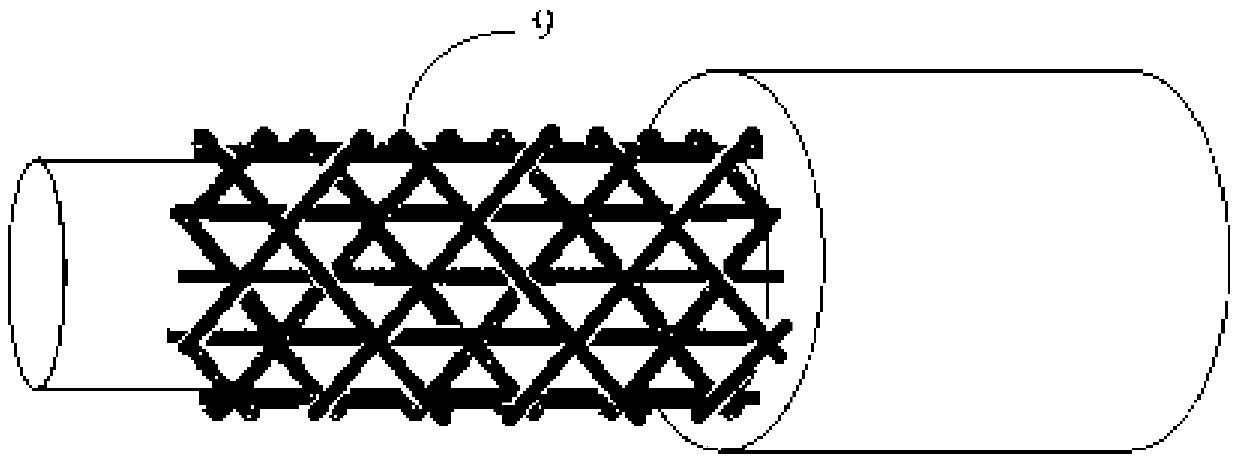

[0051] This implementation case shows a magnesium silk and silk composite braided nerve conduit structure and its preparation method, such as figure 2 As shown, the nerve guide has three layers, wherein the axis yarn 4 of the nerve guide intermediate layer 2 is magnesium wire, and four degradable titanium and nickel alloy wires 9 are symmetrically added to the braided yarn 5 to enhance the radial resistance of the nerve guide. Compressive strength, the nerve guide outer layer 1 is a porous sponge layer made of chitosan solution with a concentration of 3-6 mg / mL, and the solution concentration is 3-6 mg / mL, and the nerve guide inner layer 3 is made of chitosan with a concentration of Silk gel made from 5-10% (w / v) silk fibroin aqueous solution. The preparation process is as follows:

[0052] (1) Braiding method is used to prepare the middle layer 2 of the nerve conduit: the raw material is 20-100 D degummed silk, magnesium wire and titanium, nickel alloy wire with a diameter ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com