Coupling bionic double-circular disc furrow opener applicable to sticky and heavy soil

A double-disc and ditch opener technology, which is applied in the direction of excavation/covering trenches, application, planting methods, etc., can solve the problem of reducing the efficiency and quality of ground mechanical operations, and the difficulty of preventing sticking and drag reduction. The requirements for anti-adhesion and drag reduction are different, so as to achieve the effect of good anti-adhesion and drag reduction, strong ability of crushing soil stubble, and reducing adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

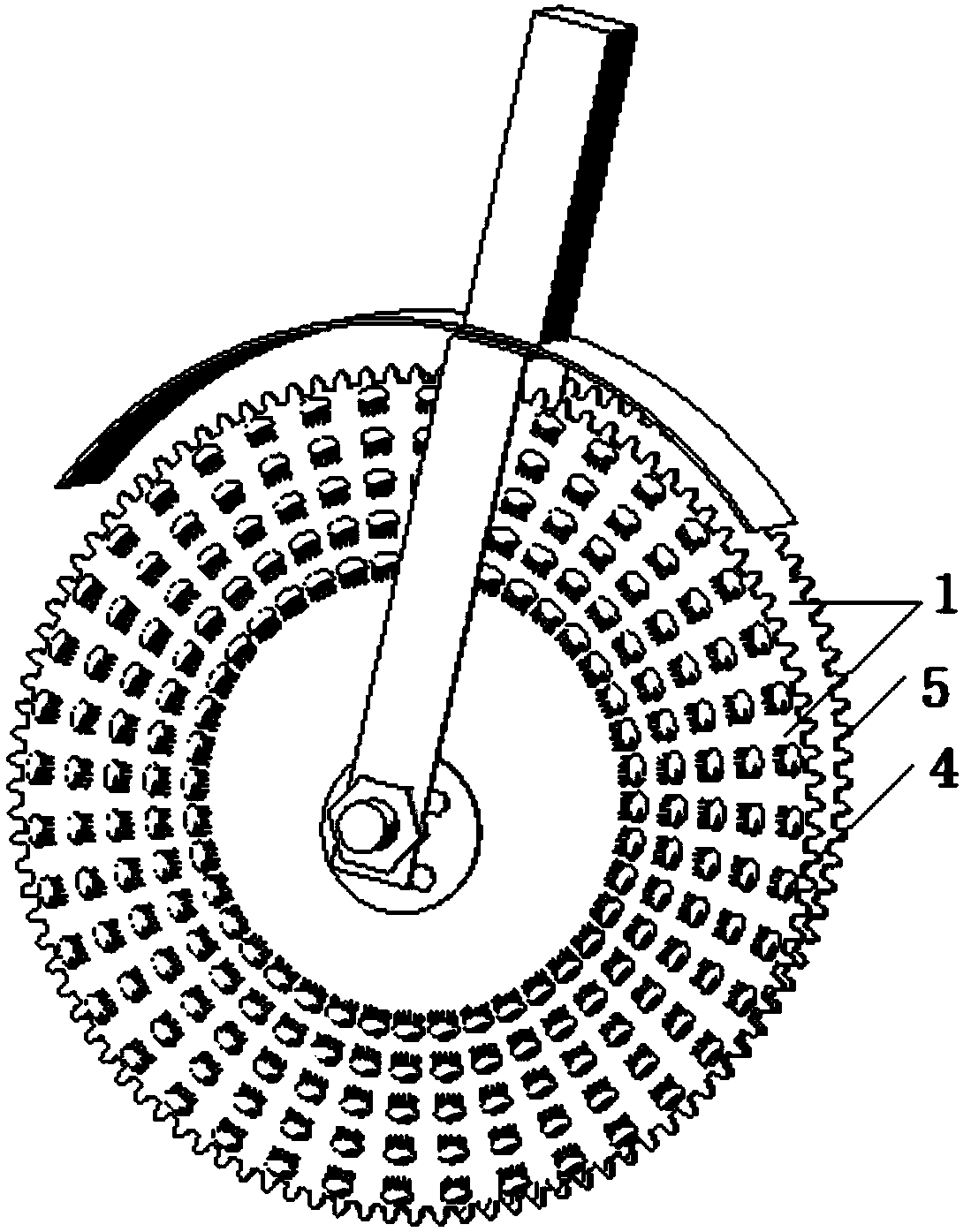

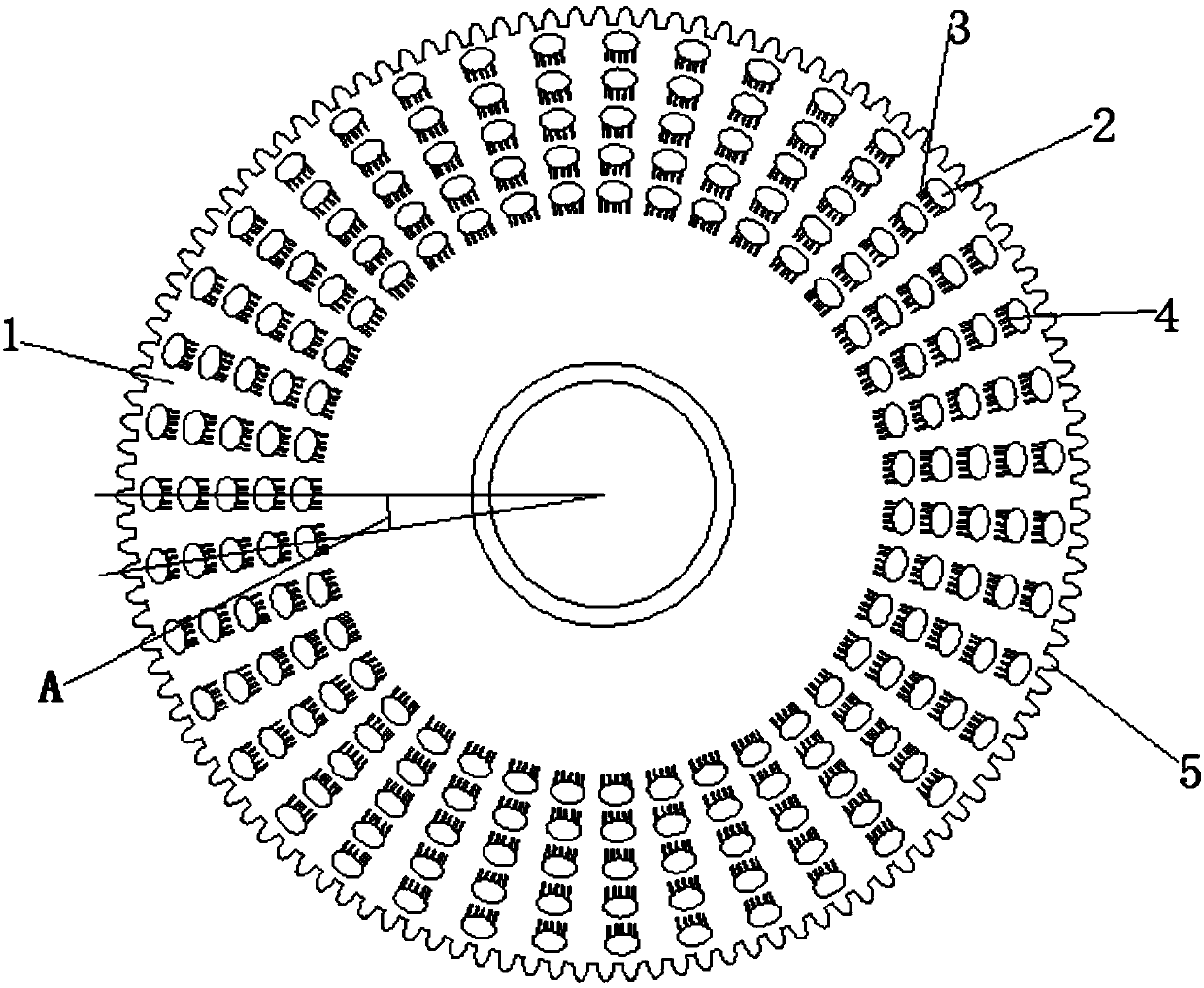

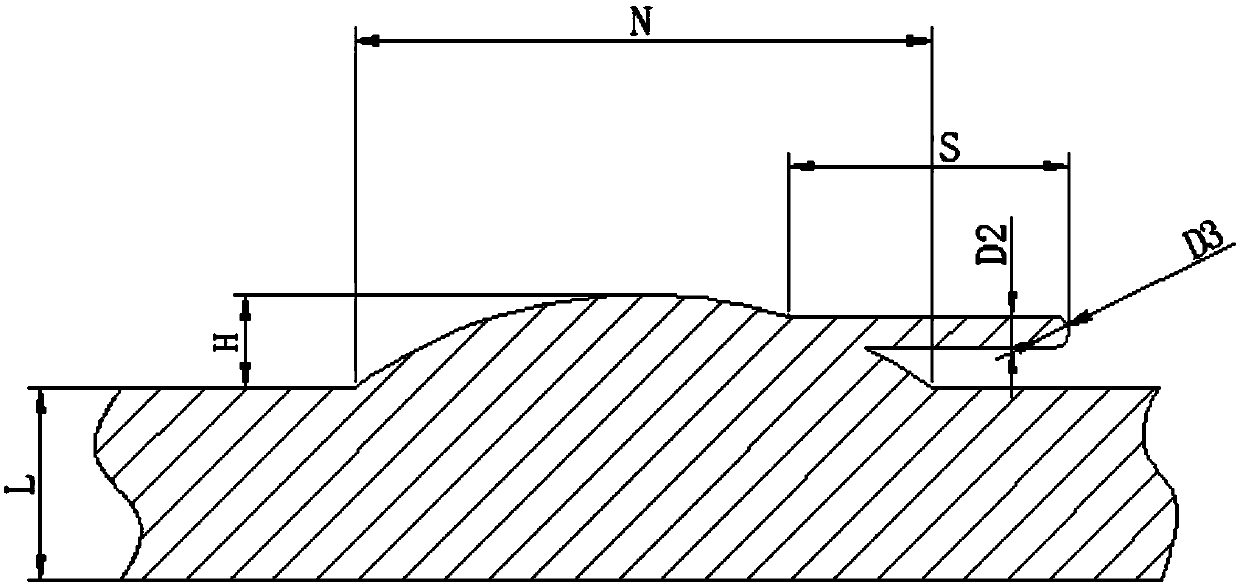

[0032] Embodiment 1: as Figure 1-6 As shown, a coupled bionic double-disc opener suitable for clay-heavy soil, the outer surfaces of the two discs 1 of the double-disc opener are provided with ellipsoidal convex hulls 2 arranged along the circumference of the disc , the flexible micro-thorns 3 are arranged on the side of the convex hull 2 of the ellipsoidal surface close to the center of the disc 1, the convex hull 2 of the curved surface of the ellipsoid and the flexible micro-thorns 3 are connected as a whole to form a bionic surface structure 4 coupled with the convex hull of the micro-thorns, This structure is uniformly distributed along the radial direction of the circumference on the working surface of the disc 1, and 5 layers are evenly arranged.

[0033] Further, the cutting edge of the disc 1 is set as a bionic sawtooth geometric mechanism 5, and its contour curve is: y=0.3x 2 , the value range of x is -18 ~ 18mm (that is, the endpoint value is taken within this...

Embodiment 2

[0043] Embodiment 2: as Figure 1-6 As shown, a coupled bionic double-disc opener suitable for clay-heavy soil, the outer surfaces of the two discs 1 of the double-disc opener are provided with ellipsoidal convex hulls 2 arranged along the circumference of the disc , the flexible micro-thorns 3 are arranged on the side of the convex hull 2 of the ellipsoidal surface close to the center of the disc 1, the convex hull 2 of the curved surface of the ellipsoid and the flexible micro-thorns 3 are connected as a whole to form a bionic surface structure 4 coupled with the convex hull of the micro-thorns, This structure is evenly distributed along the radial direction of the circumference on the working surface of the disc 1, and three layers are evenly arranged.

[0044] Further, the cutting edge of the disc 1 is set as a bionic sawtooth geometric mechanism 5, and its contour curve is: y=0.3x 2 , the value range of x is -18 ~ 18mm (that is, the endpoint value is taken within thi...

Embodiment 3

[0054] Embodiment 3: as Figure 1-6 As shown, a coupled bionic double-disc opener suitable for clay-heavy soil, the outer surfaces of the two discs 1 of the double-disc opener are provided with ellipsoidal convex hulls 2 arranged along the circumference of the disc , the flexible micro-thorns 3 are arranged on the side of the convex hull 2 of the ellipsoidal surface close to the center of the disc 1, the convex hull 2 of the curved surface of the ellipsoid and the flexible micro-thorns 3 are connected as a whole to form a bionic surface structure 4 coupled with the convex hull of the micro-thorns, This structure is uniformly distributed radially along the circumference on the working surface of the disk 1, and is evenly arranged in multiple layers.

[0055] Further, the cutting edge of the disc 1 is set as a bionic sawtooth geometric mechanism 5, and its contour curve is: y=nx 2 , wherein the value range of n is 0.12, and the value range of x is -18 ~ 18mm (that is, the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com