System and method for testing reflectivity of wave-absorbing material

A testing system and wave-absorbing material technology, which is applied in the direction of material analysis, material analysis, and measuring devices using microwave means, can solve the problems of large gear span, short service life, and easy gear jamming, etc., and achieve easy manufacturing and assembly , Stable and reliable work, high adjustment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

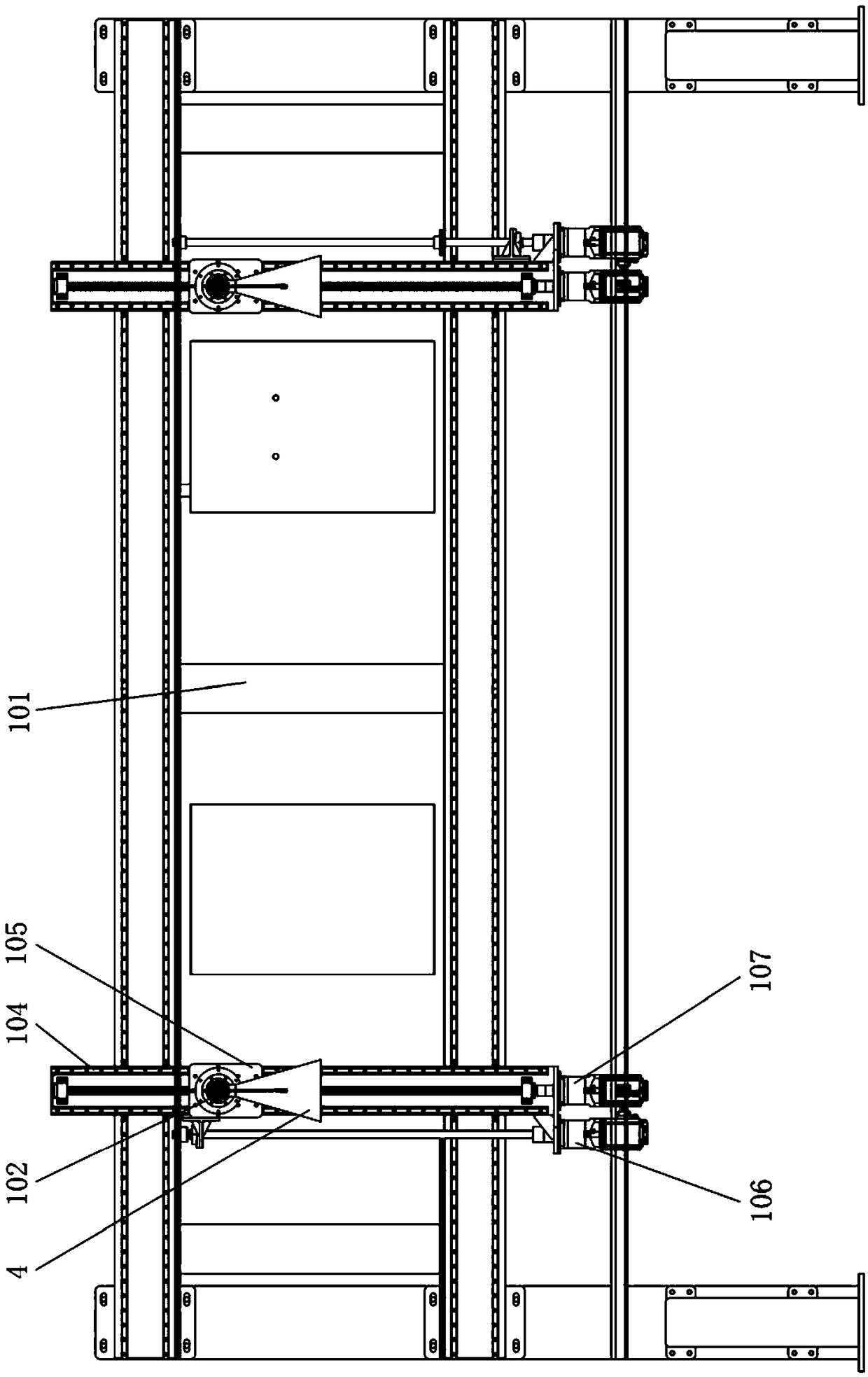

[0032] Such as Figure 1 to Figure 4 As shown, the reflectivity testing system of the absorbing material in this embodiment includes an incident angle adjustment device 1, a workpiece support platform 2 and a direct beam antenna 4, the workpiece support platform 2 is fixedly arranged, and the incident angle adjustment device 1 includes a bracket 101, a cantilever 102 and a rotary drive 103, the cantilever 102 is installed on the bracket 101 through a vertical automatic displacement component and can be driven to move in a vertical plane by the vertical automatic displacement component, the rotary drive 103 is installed on the cantilever 102, and the antenna 4 is connected with the driving end of the rotary driving member 103 and can be driven by the rotary driving member 103 to rotate around the horizontal axis. The incident angle ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com