Repeated transformation method for same-floor flooding and pressure combination production remaining geological reserves

A technology of geological reserves and repeated transformation, which is applied in the direction of earthwork drilling, production fluid, wellbore/well components, etc. It can solve the problems of limited transformation scale, limited production increase effect, and large decline, so as to expand the degree of production and improve development efficiency , the effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1 (G125-157 well):

[0037] Step 1: Perforation preparation: Prepare deep-penetrating composite perforating bullets (SYD102 / 127), preferably in layers with better physical properties at the bottom of the oil layer, with a perforation thickness of 5.0m and a perforation density of 16 holes / m to ensure oil displacement Smooth injection of fracturing fluid;

[0038] Step 2: Oil displacement fluid preparation: mix CRS surfactant at 3.75kg / m 3 The proportion of the oil displacement fracturing fluid is prepared, and the injection volume is designed to be 800m according to the length of the previous fracturing fracture. 3 ;

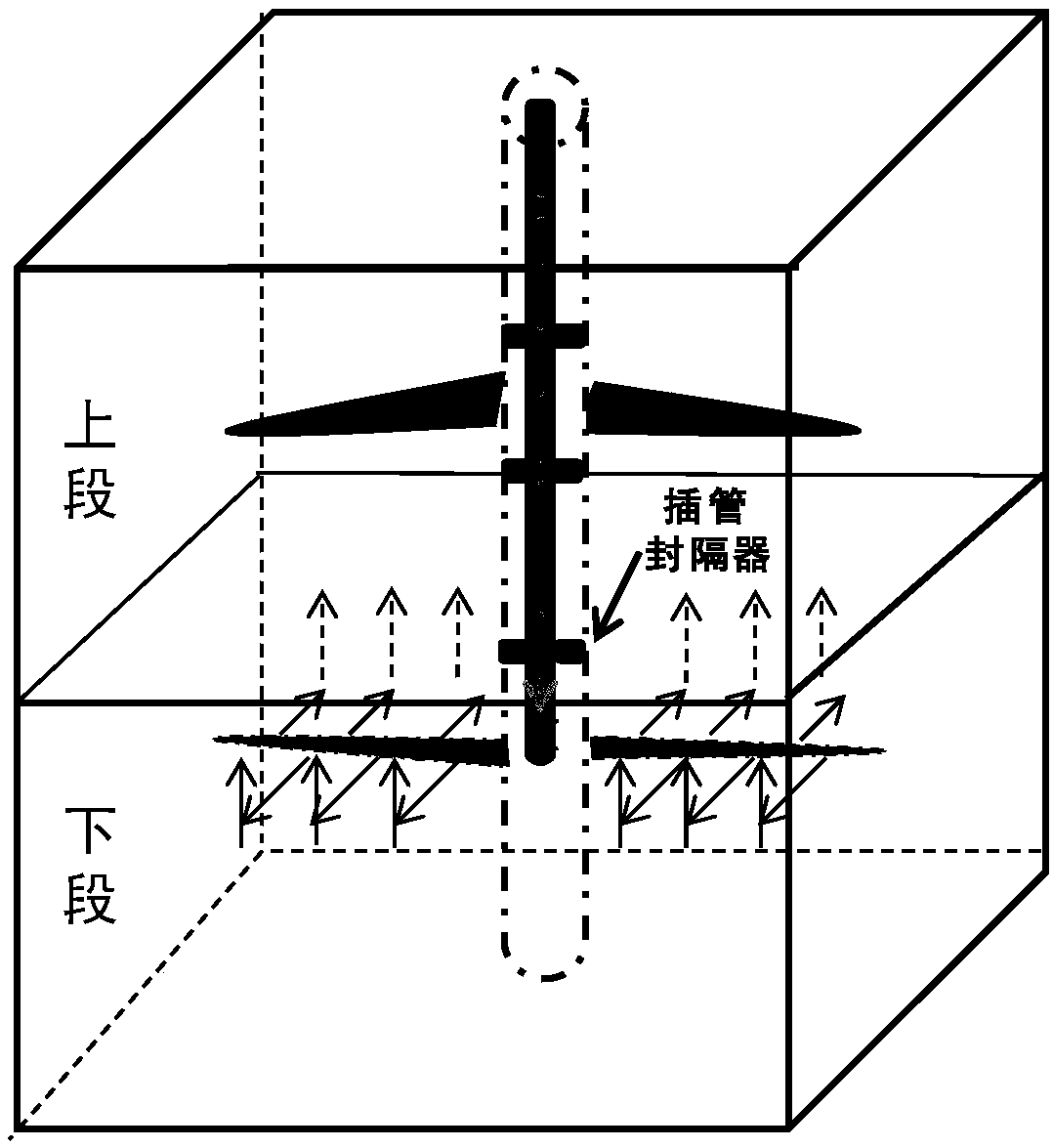

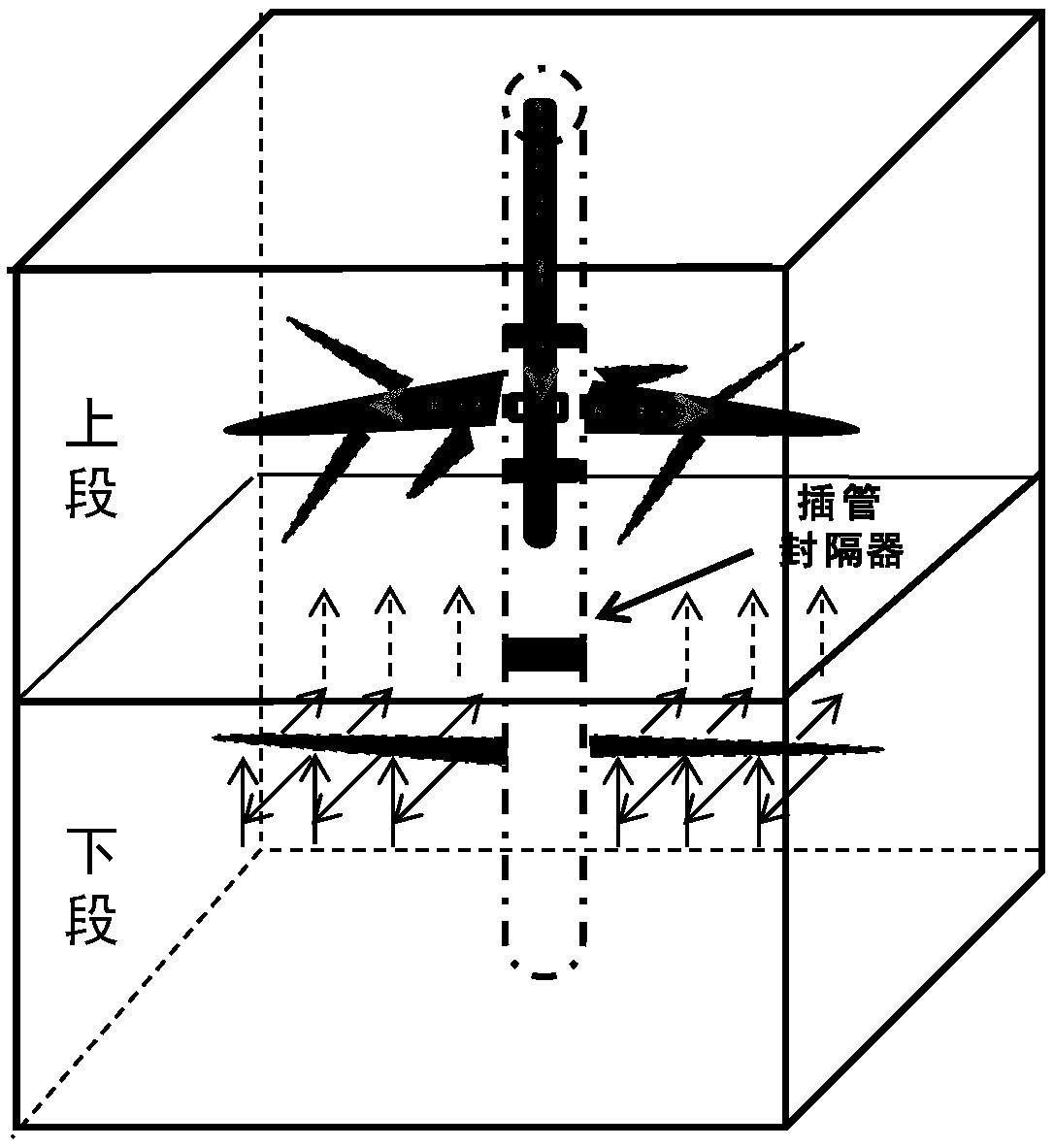

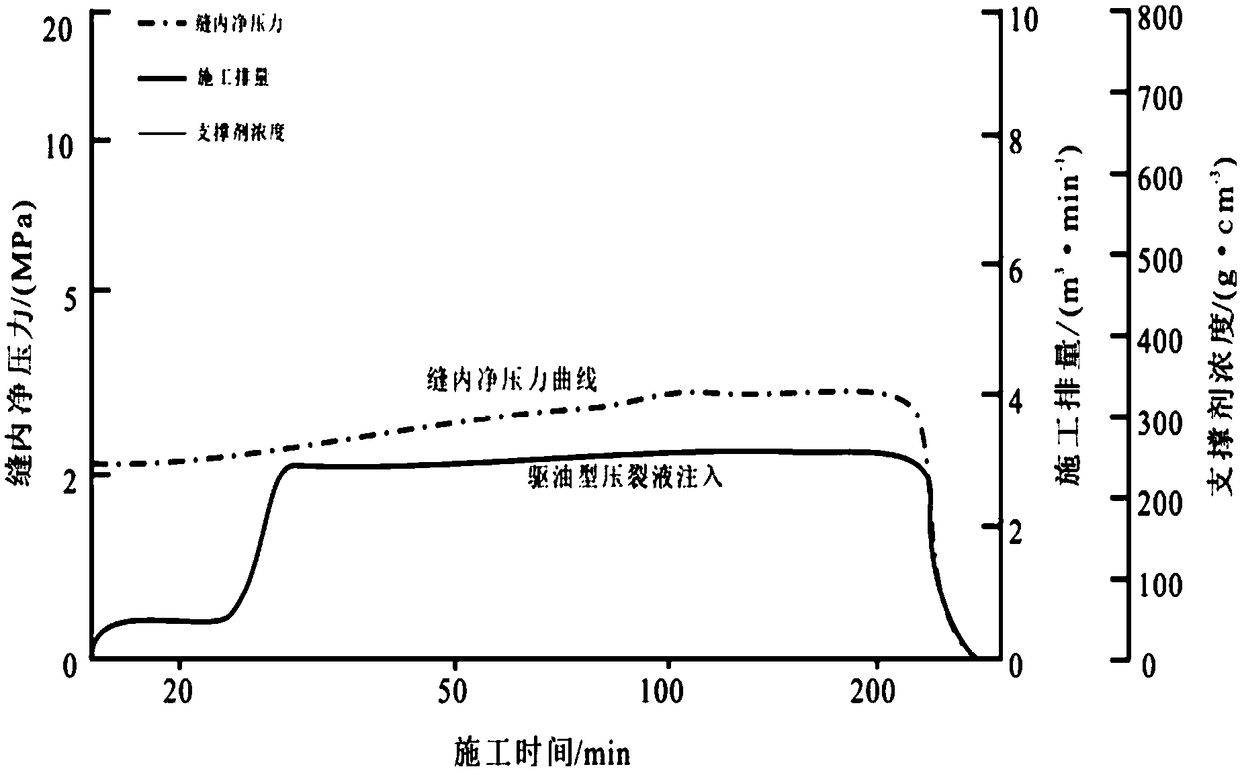

[0039] Step 3: Oil displacement fluid injection construction (see figure 2 ): double-upper casings are used for pressure injection into the pipe string, and the lower seal is an intubation-type packer. Oil-displacing fracturing fluid is used to 3 / min is injected into the new perforation section 800m 3 , the injection time is about 4.5 ho...

Embodiment 2

[0046] Step 1: Perforation preparation: prepare deep-penetrating composite perforating bullets (SYD102 / 127), select layers with better physical properties at the bottom of the oil layer, perforate thickness of 4.0m, and perforation density of 16 holes / m to ensure oil displacement Smooth injection of fracturing fluid;

[0047] Step 2: Oil displacement fluid preparation: mix CRS surfactant at 3.75kg / m 3 The proportion of the oil displacement fracturing fluid is prepared, and the injection volume is designed to be 1000m according to the length of the previous fracturing fracture. 3 ;

[0048] Step 3: Oil displacement fluid injection construction (see figure 2 ): double-upper casings are used for pressure injection into the pipe string, and the lower seal is an intubation-type packer. Oil-displacing fracturing fluid is used to 3 / min is injected into the new perforation section 1000m 3 , after the squeeze is over, the intubation packer is discarded, the injection section is s...

Embodiment 3

[0054] Step 1: Perforation preparation: prepare deep-penetrating composite perforating bullets (SYD102 / 127), select layers with good physical properties at the bottom of the oil layer, perforate thickness of 3.0m, and perforation density of 16 holes / m to ensure oil displacement Smooth injection of fracturing fluid;

[0055] Step 2: Oil displacement fluid preparation: mix CRS surfactant at 3.75kg / m 3 The proportion of the oil displacement fracturing fluid is prepared. According to the length of the previous fracturing fracture, the injection volume is designed to be 900m 3 ;

[0056] Step 3: Oil displacement fluid injection construction (see figure 2 ): double-upper casings are used to press-inject the pipe string, and the lower seal is an intubated packer. Oil-displacing fracturing fluid is used to 3 / min is injected 900m into the new perforation section 3 , after the squeeze is over, the intubation packer is discarded, the injection section is sealed, and the dialysis an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com