Repair method for concrete defect of expansion grouting pipe and tunnel lining

A repair method and concrete technology, applied in chemical instruments and methods, earthwork drilling, drilling composition, etc., can solve the problems of concrete bonding force, tunnel leakage, and sagging gravity, etc., saving time and energy. Human and material resources, protection from the danger of spark burning, good bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

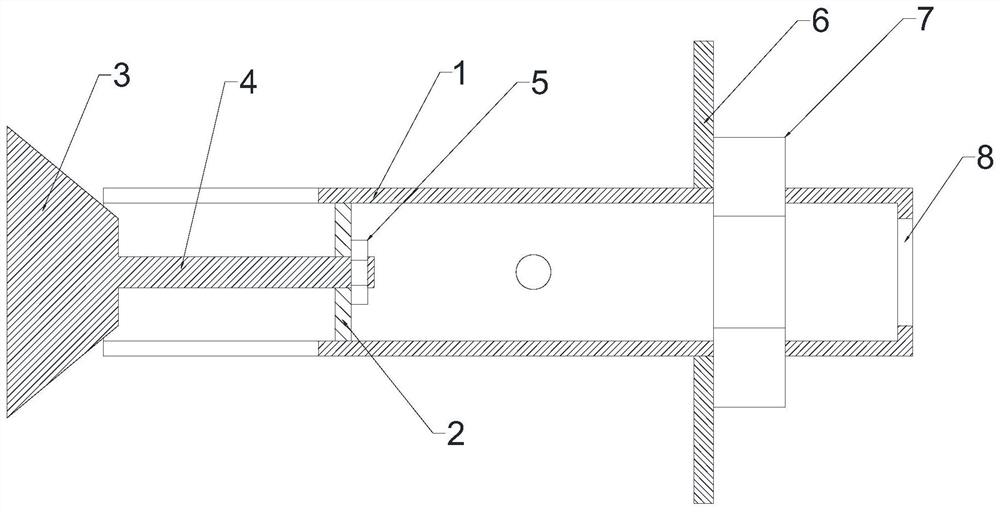

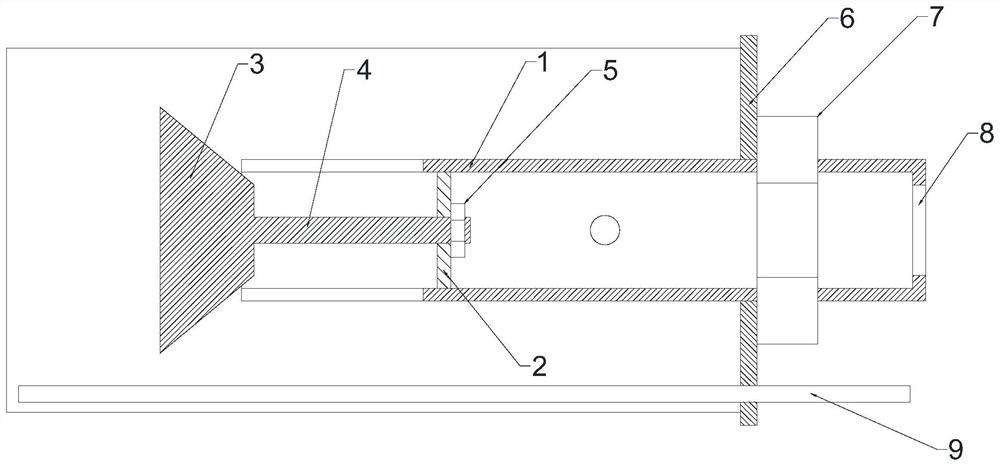

[0039] An expansion grouting pipe is provided in this embodiment, which includes a sleeve, a fixing plate, an expansion cone, an expansion rod, an expansion bolt, a tray and a fixing nut;

[0040] One end of the sleeve is provided with at least one sleeve gap along its axial direction; in this embodiment, the number of the sleeve gaps is 4, and the four sleeve gaps are evenly distributed along the circumference of the sleeve .

[0041] A fixing plate is arranged on the inner side wall of the sleeve, preferably, the fixing plate is arranged along an axis perpendicular to the sleeve, and a through hole is opened in the middle of the fixing plate.

[0042] The radius of the expansion cone gradually decreases from left to right, and the diameter of the expansion cone is larger than the inner diameter of the sleeve; one end of the expansion rod is fixed to the end with a smaller diameter of the expansion cone, and the other end Through the fixed plate, located on the right side of...

Embodiment 2

[0048] This embodiment provides a repair method for tunnel lining concrete defects. The tunnel lining concrete defects include tunnel lining concrete coring holes. The repair method includes:

[0049] S10, cleaning the core hole

[0050] In this embodiment, the dust on the inner wall of the coring hole is removed by using high-pressure gas so that when the filling material is used to fill the coring hole, good bonding force can be achieved between the filling material and the inner wall of the coring hole.

[0051] S20, install expansion grouting pipe and exhaust pipe

[0052] The expansion grouting pipe can be the expansion grouting pipe described in Embodiment 1, or other expansion grouting pipes.

[0053] When installing the expansion grouting pipe, first insert the expansion grouting pipe more than 20cm into the core hole, and fix the expansion grouting pipe.

[0054] The exhaust pipe adopts a steel pipe or iron pipe with a diameter of 8mm (the diameter of the pipe can b...

Embodiment 3

[0084] This embodiment provides a repair method for tunnel lining concrete defects, the tunnel lining concrete defects include tunnel lining concrete core holes, the repair method and the repair method in Example 2 lie in the first polyurethane spraying hard foam and the second The components and contents of the two polyurethane spray hard foams are different. Specifically, in this embodiment, the first polyurethane spray hard foam includes 100 parts by mass of PM200 and 20 parts by weight of MDI50; the second polyurethane spray hard foam The foam includes the following components in parts by weight: DL1000: 42.3; YRLK-100: 21.15; E-100: 4.1; Diethylene glycol: 7.3; flame retardant DOher6209: 14.1; foam stabilizer SD641: 0.85; KH560: 0.85; T12: 0.85; water: 0.35; and gray paste: 8.4.

[0085] Operating time, foaming ratio is tested according to JC / T2041-2010 "Polyurethane Grouting Materials", foam density is tested according to GB / T6343 "Foam Plastics and Rubber-Determination ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com