Polyester yarn dyeing technology

A polyester yarn and process technology, applied in the field of polyester yarn dyeing, can solve problems such as poor dyeing effect of polyester yarn, achieve uniform absorption and improve dyeing quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

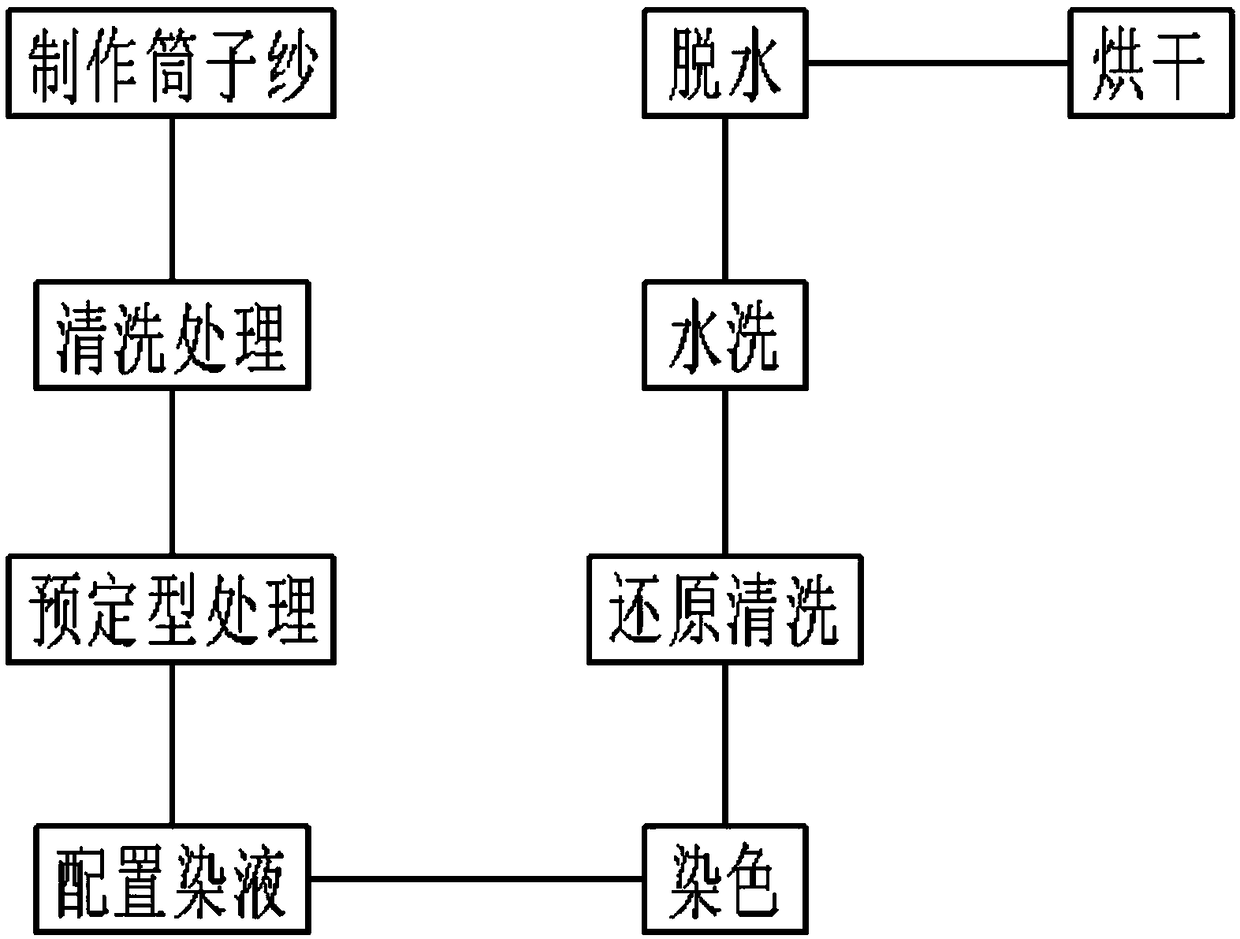

[0027] Example 1: Please refer to figure 1 , a polyester yarn dyeing process, a polyester yarn dyeing process, comprising the following steps: making cheese, cleaning treatment, pre-setting treatment, dye liquor configuration, dyeing, reduction cleaning, washing, dehydration, drying; specifically:

[0028] (1) Production of bobbins: including loose yarns and cages, the tight bobbins are rewound into loose bobbins with a winding density of 0.32g / cm3 through a spinning machine, which can effectively prevent the phenomenon of dyeing during dyeing and eliminate The internal and external color difference ensures smooth dyeing, and the appearance of the original gray yarn can also be inspected during the loosening process. Install the loose bobbin on the sarong as required for dyeing. When loading the bobbin from bottom to top, the small opening faces upwards and the large opening faces downward. The sleeve can be loaded into the tube; when loading the cage, the tube should be hand...

Embodiment 2

[0041] Example 2: Please refer to figure 1 , a polyester yarn dyeing process, a polyester yarn dyeing process, comprising the following steps: making cheese, cleaning treatment, pre-setting treatment, configuring dye liquor, dyeing, reduction cleaning, washing, dehydration, drying; specifically:

[0042] (1) Production of bobbin yarn: including loose yarn and cage loading, the tight bobbin yarn is rewound into a loose bobbin with a winding density of 0.34g / cm3 through a loose yarn machine, which can effectively prevent the phenomenon of dyeing during dyeing and eliminate The internal and external color difference ensures smooth dyeing, and the appearance of the original gray yarn can also be inspected during the loosening process. Install the loose bobbin on the sarong as required for dyeing. When loading the bobbin from bottom to top, the small opening faces upwards and the large opening faces downward. The sleeve can be loaded into the tube; when loading the cage, the tube ...

Embodiment 3

[0055] Example 3: Please refer to figure 1 , a polyester yarn dyeing process, a polyester yarn dyeing process, comprising the following steps: making cheese, cleaning treatment, pre-setting treatment, configuring dye liquor, dyeing, reduction cleaning, washing, dehydration, drying; specifically:

[0056] (1) Production of bobbins: including loose yarns and cages, rewinding the tight bobbins through the loosening machine into loose bobbins with a winding density of 0.36g / cm3, which can effectively prevent the phenomenon of dyeing during dyeing and eliminate The internal and external color difference ensures smooth dyeing, and the appearance of the original gray yarn can also be inspected during the loosening process. Install the loose bobbin on the sarong as required for dyeing. When loading the bobbin from bottom to top, the small opening faces upwards and the large opening faces downward. The sleeve can be loaded into the tube; when loading the cage, the tube should be handl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com