Printing and dyeing pretreatment process for imitated silk fabric

A technology of imitating silk and fabrics, which is applied in the processing of textile materials, continuous processing of textile materials, spraying/jetting of textile materials, etc. It can solve the problems of fabric printing and dyeing quality, and achieve enhanced dyeing quality, reduced wrinkles, and enhanced cleaning effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Roll the same specification of the grey fabric, reserve a joint before rolling, use a sewing machine to connect the rolled grey fabric to the joint of another roll of grey fabric, and connect multiple rolls of grey fabric in the same way.

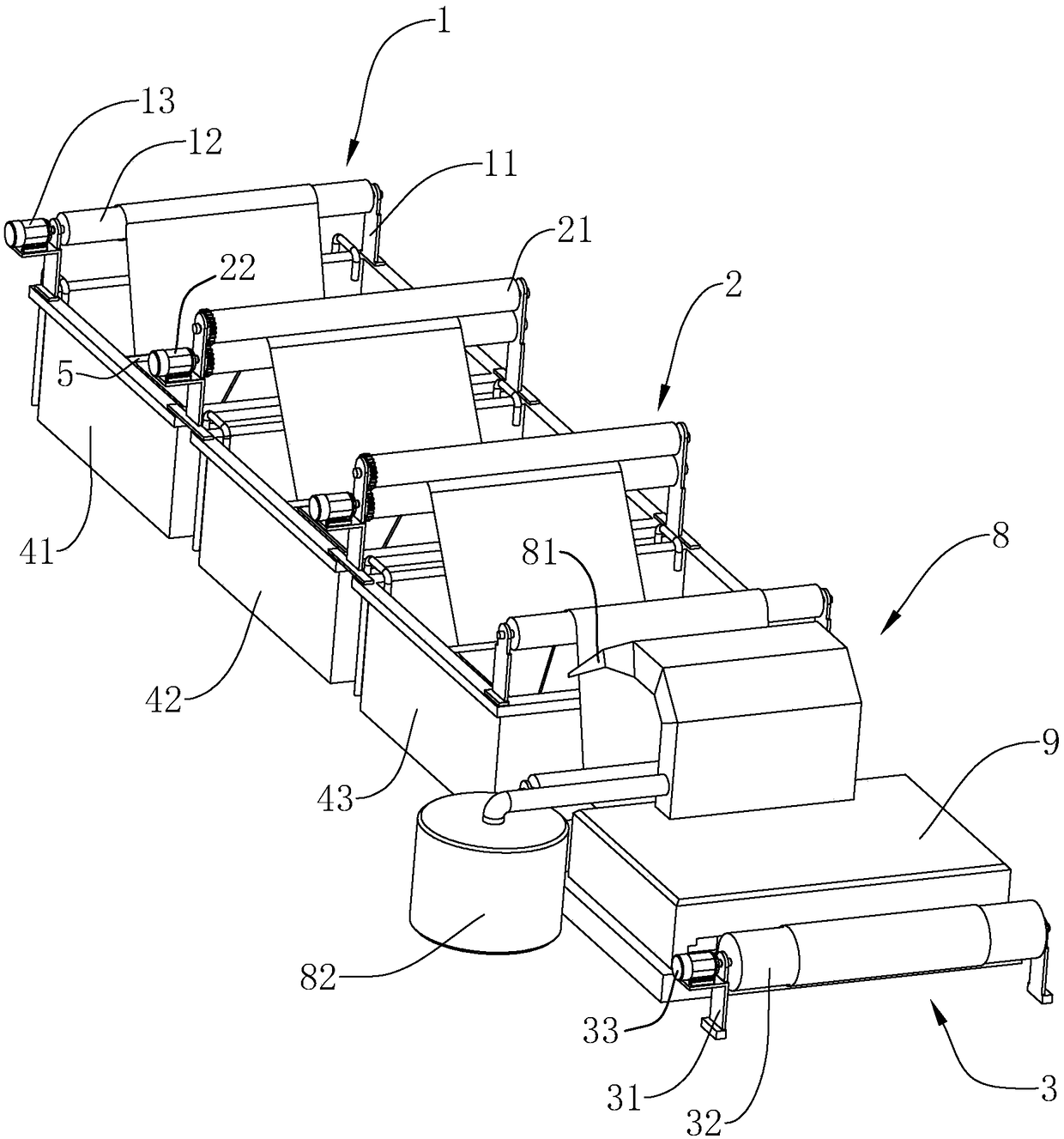

[0045] Such as figure 1 As shown, the rolled grey fabric is installed on the unwinding device 1, and the transmission device 2 is used to make the grey fabric pass through the desizing tank 41, the first cleaning tank 42, and the second cleaning tank 43 in sequence. Wherein, the desizing tank 41, the first cleaning tank 42 and the second cleaning tank 43 are all rotatably connected with a cloth pressing rod 5, which is made of polytetrafluoroethylene and arranged horizontally. The desizing tank 41, the first cleaning tank 42, and the second cleaning tank 43 are also provided with overflow ports.

[0046] Reference figure 1 , The desizing tank 41 is provided with a desizing solution, the desizing solution floods the cloth press rod 5 in th...

Embodiment 2

[0054] Roll the same specification of the grey fabric, reserve a joint before rolling, use a sewing machine to connect the rolled grey fabric to the joint of another roll of grey fabric, and connect multiple rolls of grey fabric in the same way.

[0055] Such as figure 2 As shown, the rolled grey fabric is installed on the unwinding device 1, and the transmission device 2 is used to make the grey fabric pass through the desizing tank 41, the first cleaning tank 42, and the second cleaning tank 43 in sequence. The desizing tank 41, the first cleaning tank 42 and the second cleaning tank 43 are all rotatably connected with a cloth pressing rod 5, which is made of polytetrafluoroethylene and arranged horizontally. The desizing tank 41, the first cleaning tank 42, and the second cleaning tank 43 are also provided with overflow ports.

[0056] Reference figure 2 The desizing tank 41 is provided with a desizing liquid, and the desizing liquid floods the cloth pressing rod 5 in the desi...

Embodiment 3

[0066] Except that the unloading rate of the unwinding device 1 is replaced with 4000m / h, the spraying rate of the steam injection device 8 is replaced with 8m / s, and the setting temperature of the gray fabric of the setting machine 9 is replaced with 180°C, the rest of the operations are the same as those in the embodiment. 2 is the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com