A production method of linseed oil and its vacuum low-temperature pressing device

A technology of linseed oil and production method, which is applied in the direction of fat oil/fat production, press, fat production, etc., can solve the problems of reducing the nutritional and physiological activity of linseed oil, high maintenance cost of extraction technology equipment, and affecting the quality of oil, etc. Achieve the effects of shortening the process, high shelling efficiency and improving oil yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

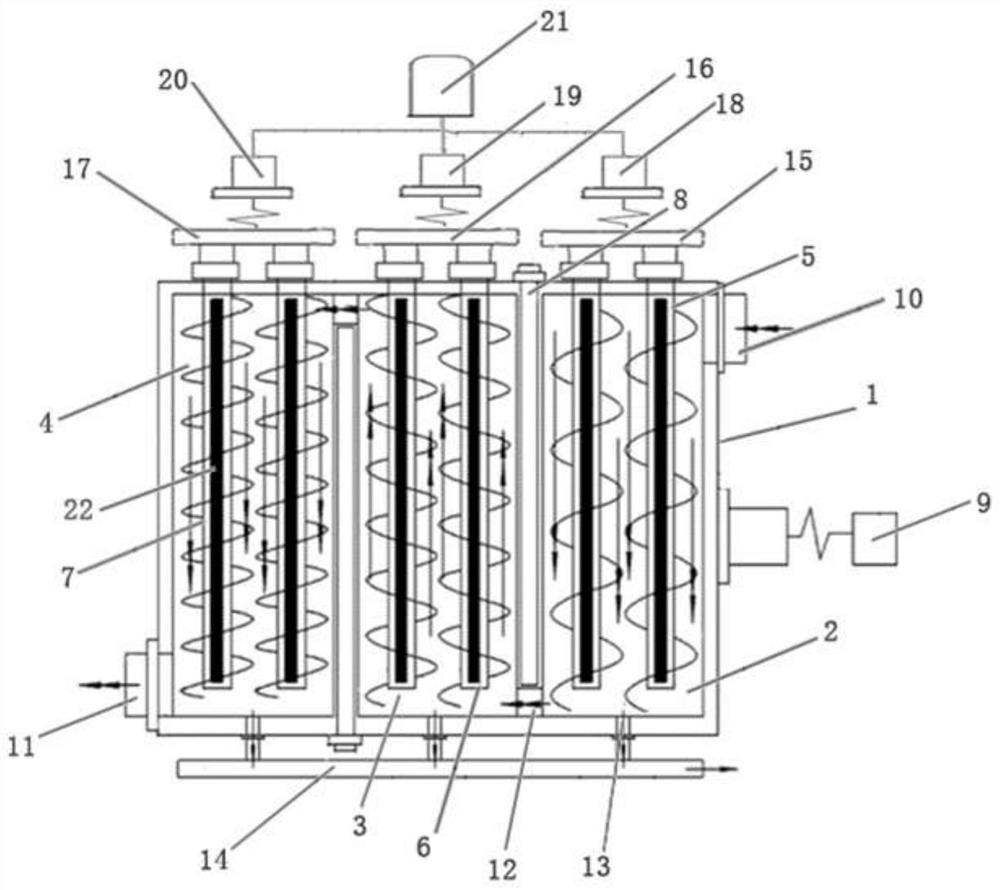

Image

Examples

Embodiment 3

[0058] Screening Example 3: Preferred Screening Example 1, the process parameters of the processing process of Example 2 were screened, and the linen of the high pressure pulse electric field, the ultrasonic pulse process was combined, and the flaxseed oil was prepared:

[0059] 2.5kg linen is placed in a high pressure pulse electric field for pretreatment, and the pulse electric field strength is 26 kV / cm. The pulse width is 20 μs, the temperature is 38 ° C, the treatment time is 4 minutes, which is a lamelifted linen; The conveyance to the crusher is broken, the particle size is 0.8 to 1 mm of crude granules; then the crude granular linen is delivered to the ultrasonic chamber for ultrasonic treatment, and the ultrasonic wave is 18 kHz, the temperature is 33 ° C, the treatment time is 8min, get pressing materials; then press the pressing material to vacuum and low-temperature pressed oil, the vacuum is 0.06 MPa, the temperature is 32 ° C, the treatment time is 90 min, and the ...

preparation Embodiment 1

[0063] The production method of the linseed oil of the present preparation includes the following steps:

[0064] A, shell and sheath housing separation: screening lossless, copied, no dry, high quality clean flax seeds, put high-quality flaxseed into the bag, put the ultra high pressure equipment, seal, pressurize to 358MPa, the holding time is 4 minutes Remove the shell, then linen, the linen mixture is separated by high-speed rotating fan, separating linen, linen shell, gaining linen, spare;

[0065] B, high pressure pulse electric field pretreatment: 35kg linen is placed in a high pressure pulse electric field for pretreatment, the pulse electric field strength is 22kV / cm, the pulse width is 17μs, the temperature is 36 ° C, the treatment time is 3 min, and the tiened linen ;

[0066] C, Brave: Transferring the ripening linen to the crusher to break, get the particle size of 0.8 ~ 1 mm, crude granular layer;

[0067] D, ultrasonic reprocessing: convey the crude granular linen...

preparation Embodiment 2

[0075] The production method of the linseed oil of the present preparation includes the following steps:

[0076] A, shell and shell shell separation: screening lossless, copied, no dry, high quality clean flax seeds, put high-quality flaxseed into the bag, put ultra high pressure equipment, seal, pressurize to 482MPa, pressure pressure time is 5 min Remove the shell, then linen, the linen mixture is separated by high-speed rotating fan, separating linen, linen shell, gaining linen, spare;

[0077] B, high pressure pulse electric field pretreatment: 35kg linen is placed in a high pressure pulse electric field for pretreatment, the pulse electric field strength is 25kV / cm, the pulse width is 18 μs, the temperature is 37 ° C, the treatment time is 4 minutes, and the labin is obtained. ;

[0078] C, Brave: Transferring the ripening linen to the crusher to break, get the particle size of 0.8 ~ 1 mm, crude granular layer;

[0079] D, Ultrasonic Regeneration: Transferring the crude gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com