Chromate-acrylic resin masking liquid with good secondary coating adhesiveness and preparation method and application thereof

A acrylic resin and chromate technology, applied in coatings, anti-corrosion coatings, etc., can solve problems such as difficulty in meeting the individual needs of users, not involving the adhesion of secondary coatings, environmental protection C6 thick coatings, etc. Coating compatibility issues, improving the acid resistance of acrylic resin, and improving the effect of coating film quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

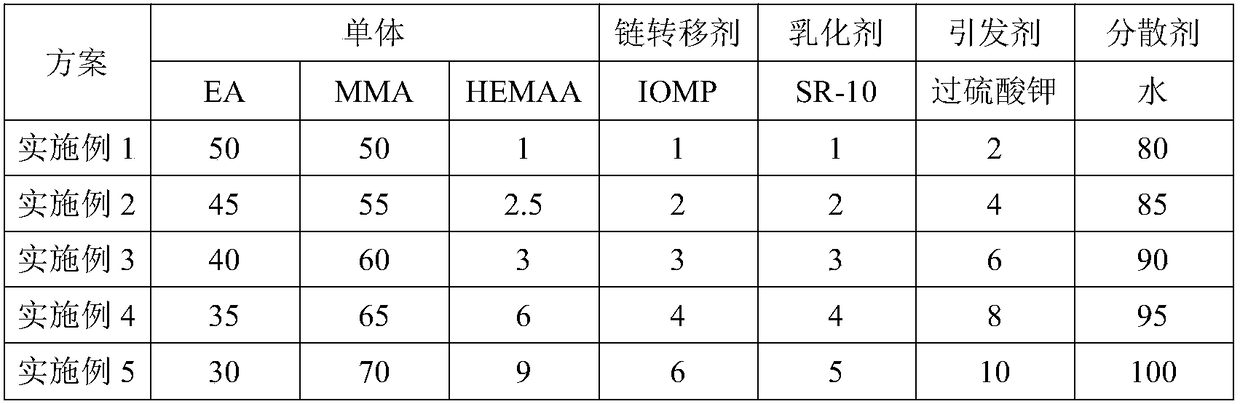

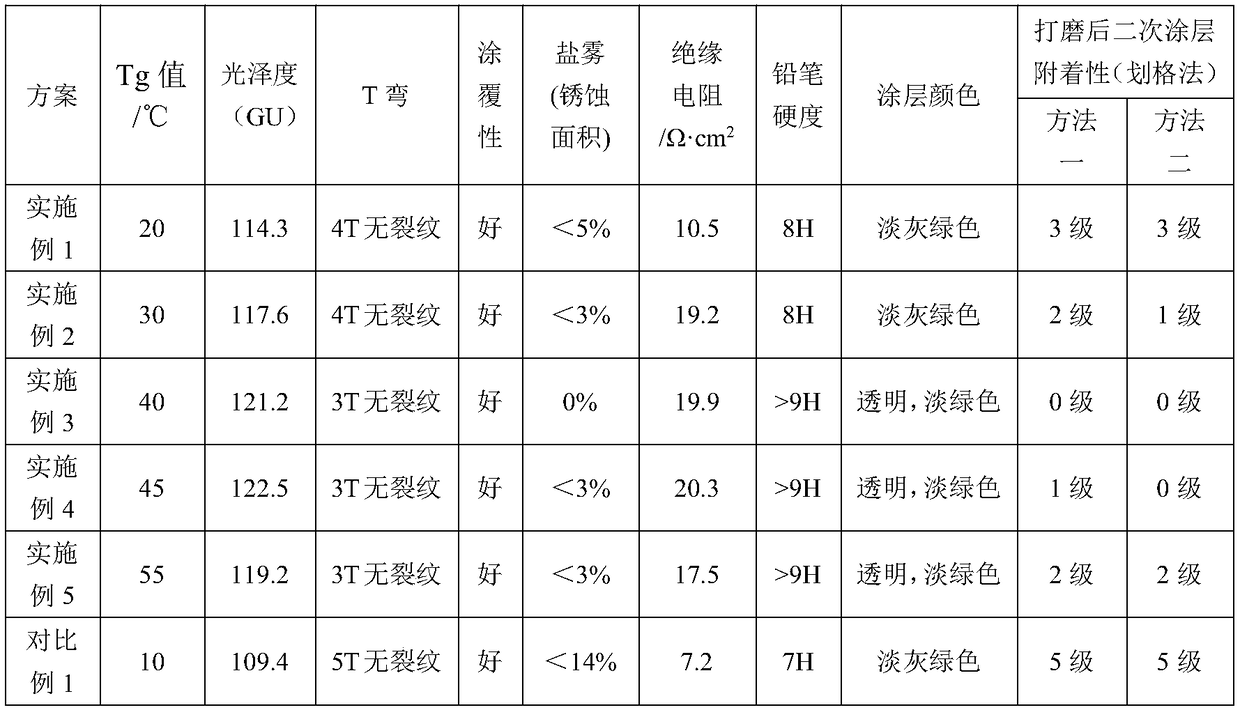

[0035]The chromate-acrylic resin coating solution with good secondary coating adhesion provided by the present invention is composed of inorganic components, polyhydric alcohols, and acrylic emulsion in a mass ratio of (5-20): (0.1-1.0): 1 , the specific proportioning of each embodiment is shown in Table 1; the inorganic components include 1-8 parts of magnesium oxide, 14-29 parts of chromic anhydride, 0.1-0.8 parts of boric acid and 50-95 parts of water in parts by mass. See Table 4 for comparison; the acrylic emulsion includes 40-70 parts by mass of pre-emulsion, 1-8 parts of sodium bicarbonate and 40-70 parts of water, and the specific proportions are shown in Table 3; 1-5 parts of allyloxy fatty alcohol oxyethylene ether ammonium sulfate, 2-10 parts of potassium persulfate, 50-70 parts of methyl methacrylate, 30-50 parts of ethyl acrylate, N-hydroxyethyl acrylamide 1 to 10 parts, 1 to 6 parts of chain transfer agent and 80 to 100 parts of water are pre-emulsified, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com