Pumping agent for hydraulic reclamation of silt solidified soil and preparation method thereof

A technology of dredging sludge and solidified soil, which is applied in chemical instruments and methods, fixed/solidified sludge treatment, sludge treatment, etc. It can solve the problem of undiscovered sludge solidified soil and how to improve the flow of freshly mixed sludge solidified soil In order to achieve the effect of prolonging the pumpable construction time, ensuring the shear fluidity of the slurry, and maintaining the stability of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

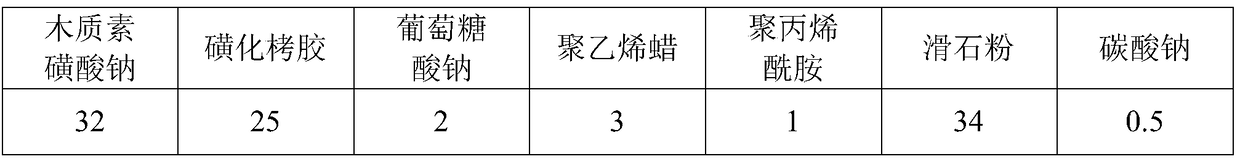

[0046] In this example, the composition of the pumping agent for dredging and filling silt-solidified soil is shown in Table 1. The prepared pumping agent is used for dredging and filling construction of silt-solidified soil in the center of a seawall in Zhejiang, and the amount of pumping agent added is 0.2kg / m 3 (volume of silt slurry), see Table 11 for relevant performance indicators of silt-solidified soil.

[0047] Table 1 Composition of pumping agent (unit: part)

[0048]

Embodiment 2

[0050] In this example, the composition of the pumping agent for dredging and filling silt-solidified soil is shown in Table 2. The prepared pumping agent is used for dredging and filling construction of silt-solidified soil in the center of a seawall in Zhejiang, and the amount of pumping agent added is 0.2kg / m 3 (volume of silt slurry), see Table 11 for relevant performance indicators of silt-solidified soil.

[0051] Table 2 Composition of pumping agent (unit: part)

[0052]

Embodiment 3

[0054] In this example, the composition of the pumping agent for dredging and filling silt-solidified soil is shown in Table 3. The prepared pumping agent is used for dredging and filling construction of silt-solidified soil in the center of a seawall in Zhejiang, and the amount of pumping agent added is 0.2kg / m 3 (volume of silt slurry), see Table 11 for relevant performance indicators of silt-solidified soil.

[0055] Table 3 Composition of pumping agent (unit: part)

[0056]

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com