Method for purifying zinc electrodeposition anode mud to prepare manganese sulfate and cell grade manganese dioxide

A manganese dioxide and anode slime technology, applied in the field of metallurgy, can solve the problems of loss of smelting energy consumption of non-ferrous metals with slag, increase of slag amount in lead smelting smelting system, and high manganese ion in system solution, so as to achieve superior cycle stability and product quality. Stable, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A method for purifying and preparing manganese sulfate from zinc electrodeposition anode slime, comprising the following steps:

[0032] (1) Perform ball milling on the zinc electrodeposition anode slime (its composition content is shown in Table 1), then weigh 1200g of zinc electrodeposition anode slime after ball milling and 3600mL of deionized water, wash zinc under mechanical stirring conditions, and filter Obtain the first section of zinc washing slag and the first section of zinc washing solution; the first section of zinc washing solution is carried out for resource recycling, and 3600mL deionized water is added to the first section of zinc washing slag to carry out the second section of zinc washing, filtered and dried to obtain Zinc washing slag;

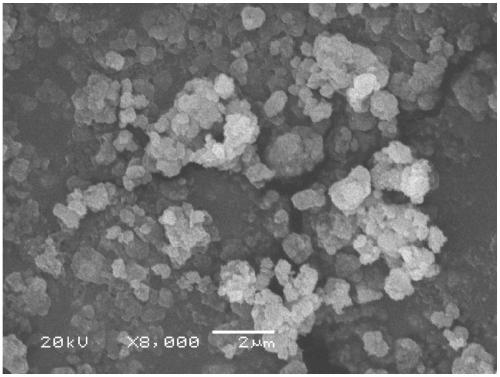

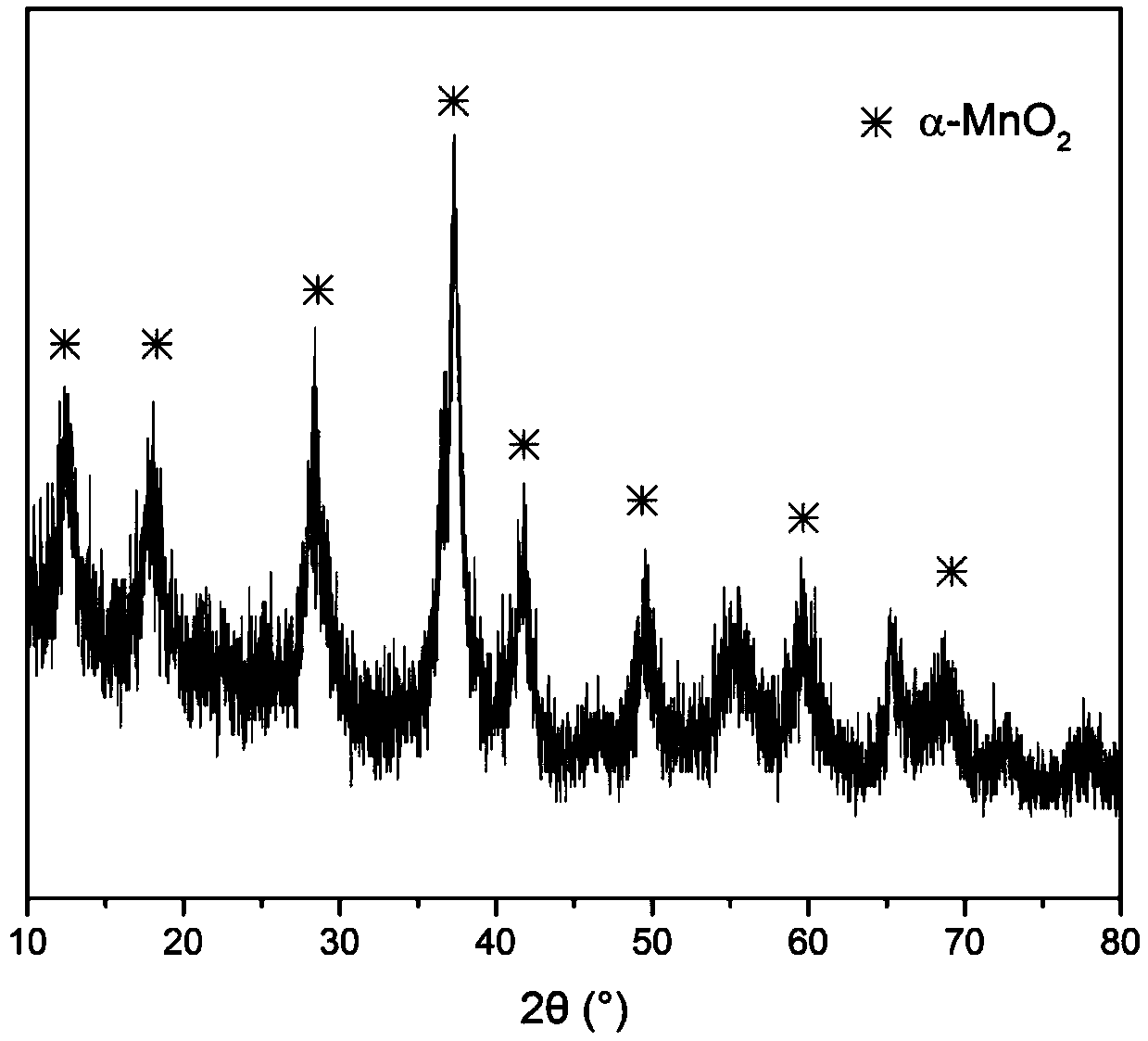

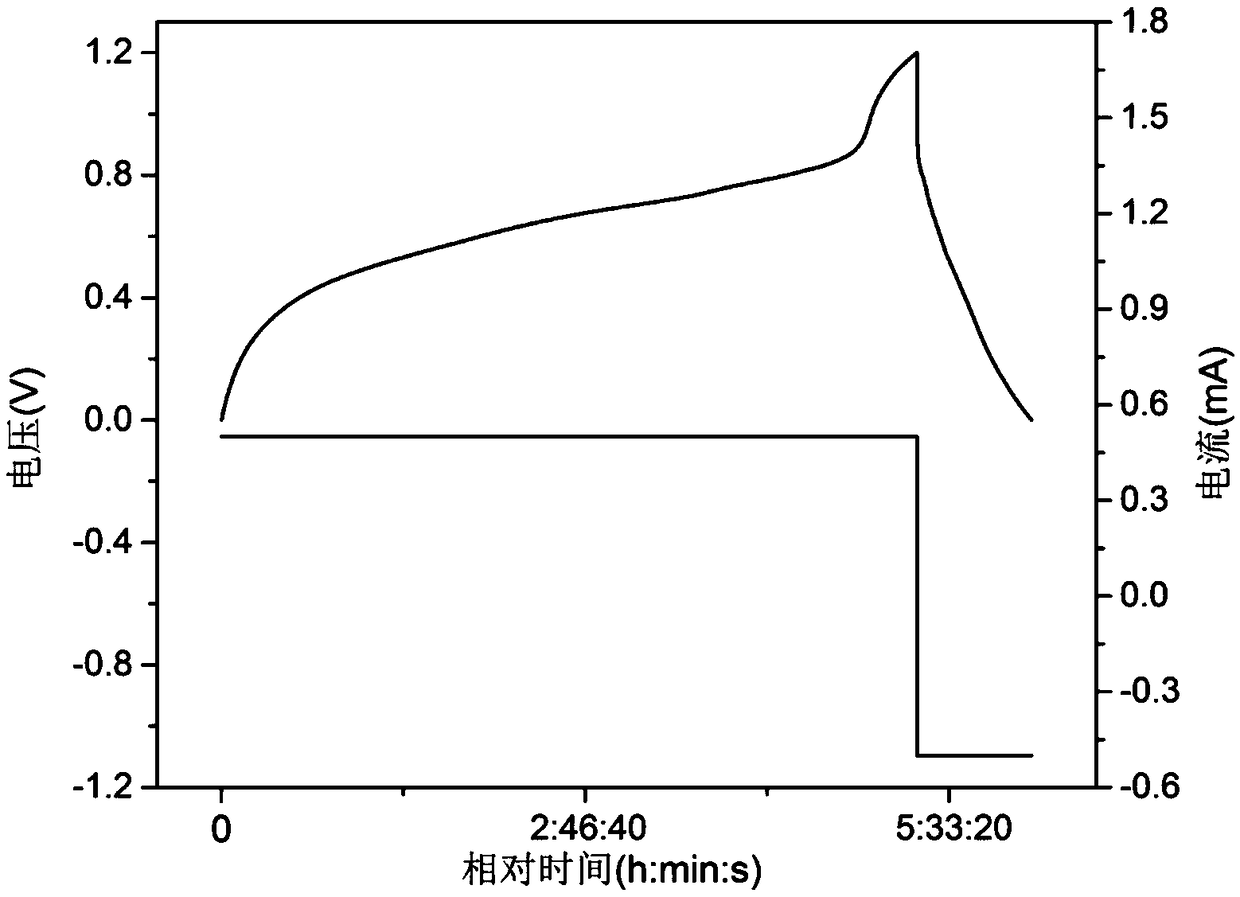

[0033] (2) Take 500g of zinc washing slag and add it to 2500mL of deionized water, and feed SO with a gas flow rate of 1L / min and an excess coefficient of 1.4 times 2 Reductively leaching manganese to obtain a manga...

Embodiment 2

[0063] A method for purifying and preparing manganese sulfate from zinc electrodeposition anode slime, comprising the following steps:

[0064] (1) Carry out ball milling of the zinc electrodeposition anode slime, then weigh 1200g of the zinc electrodeposition anode slime pulverized by the ball mill and mix it with the second-stage zinc washing solution in 3600mL of Example 1, wash zinc under mechanical stirring conditions, and filter Finally, the first section of zinc washing slag and the first section of zinc washing solution are obtained; the first section of zinc washing solution is used for resource recycling, and 3600mL deionized water is added to the first section of zinc washing slag to carry out the second section of zinc washing, filtered and dried Get zinc washing slag;

[0065] (2) Take 500g of zinc washing slag and add it to 2500mL of deionized water, and feed SO with a gas flow rate of 1L / min and an excess coefficient of 1.4 times 2 Reductively leaching manganes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

| Dc resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com