High-voltage power distribution device and method

A technology of high-voltage power distribution and resistance, which is applied in the direction of electrical equipment, electric vehicles, transportation and packaging, etc. The role of breaking and other problems, to reduce the effect of the probability of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention will be described in further detail below in conjunction with the accompanying drawings.

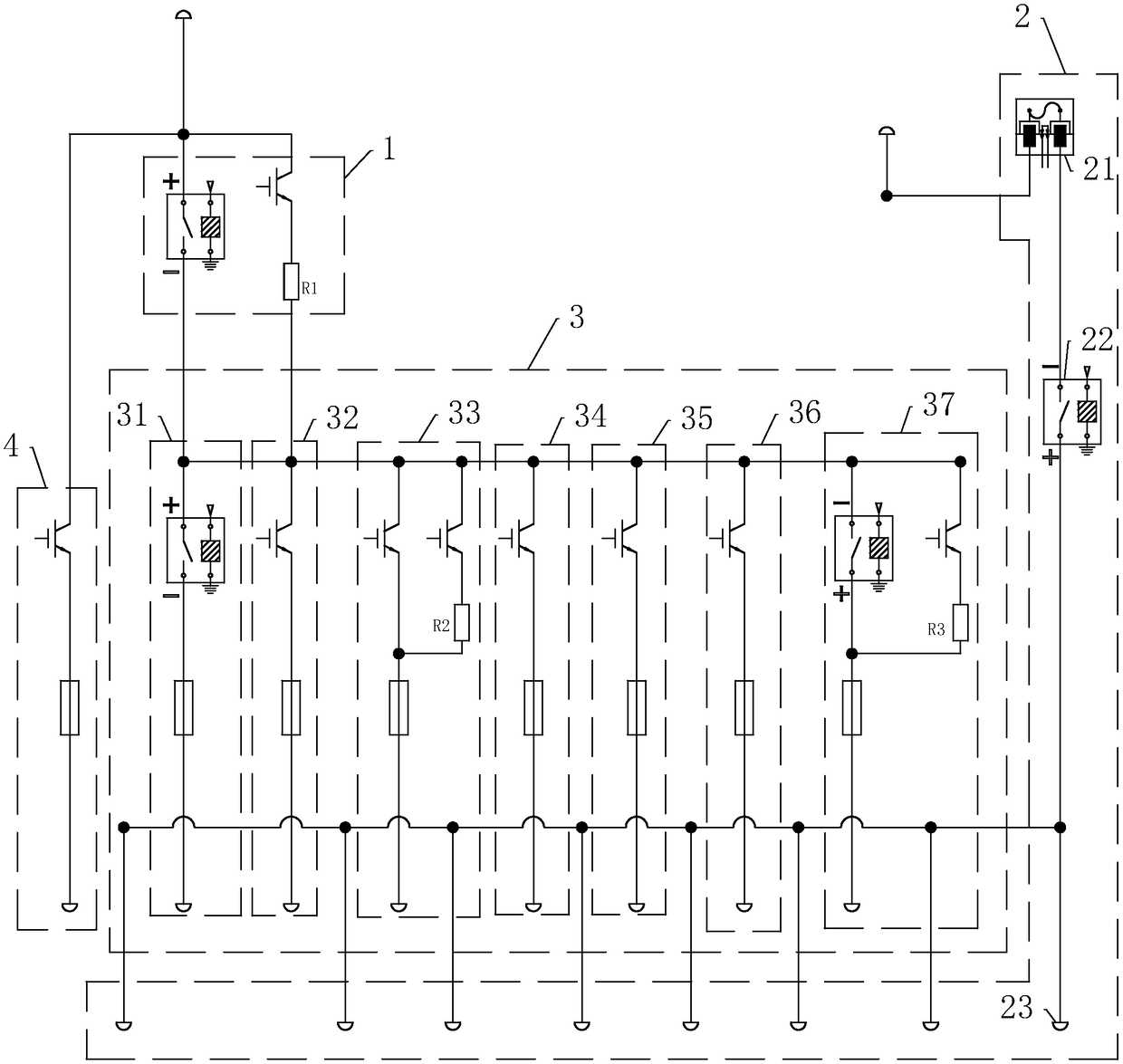

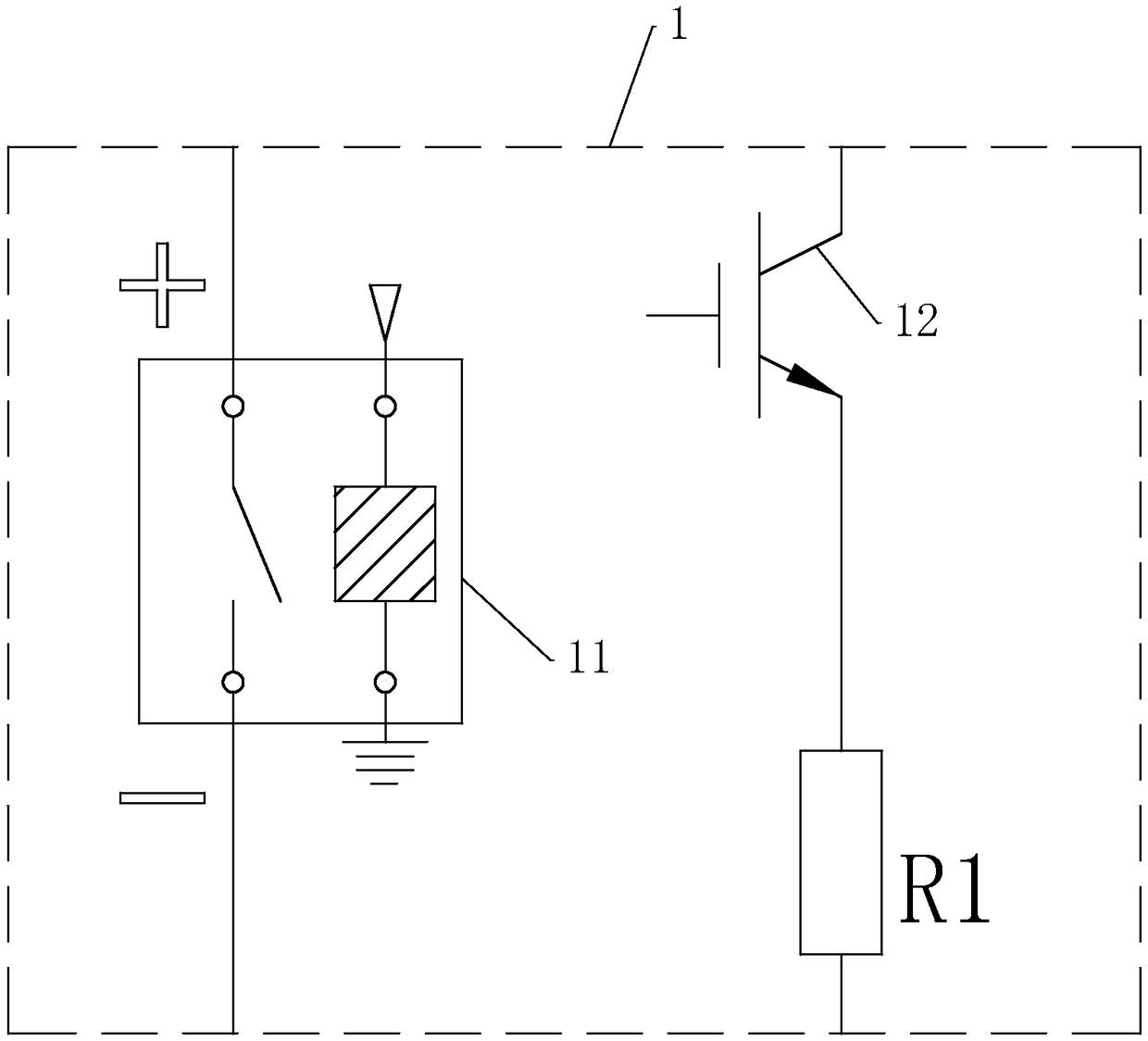

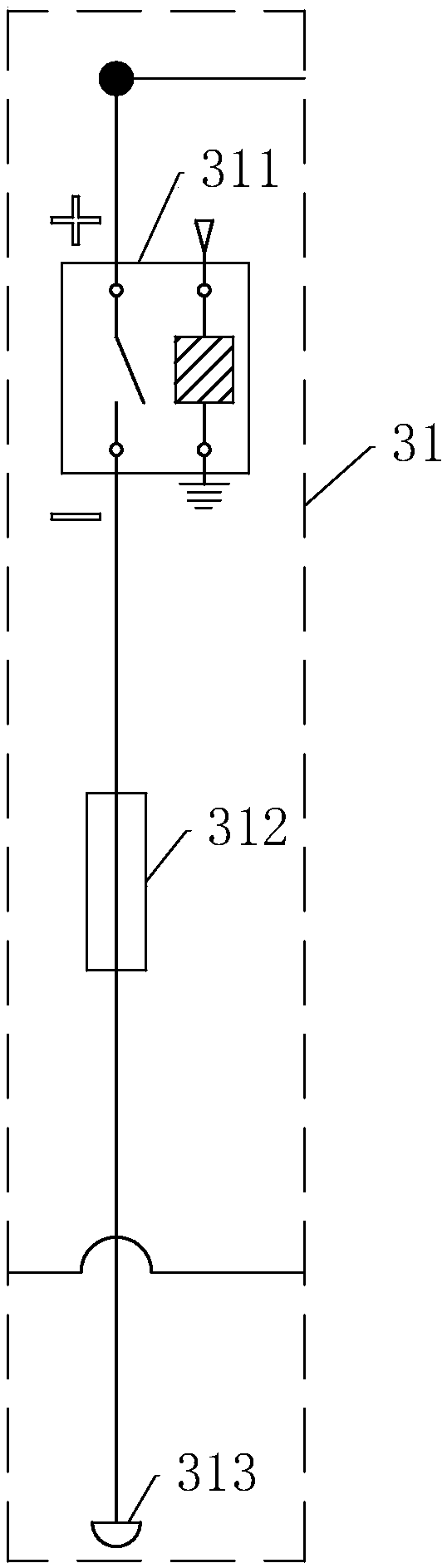

[0059] refer to figure 1 with figure 2 , is a high-voltage power distribution device disclosed in the present invention, comprising a main positive on-off component 1 connected to the positive pole of the power supply, a main negative on-off component 2 connected to the negative pole of the power supply and the equipment on both ends, and the two ends are respectively connected to the main positive The group control component 3 that disconnects component 1 and equipment connection. The main positive on-off assembly 1 includes a main positive contactor 11, a positive switch 12 and a resistor R1. The main positive contactor 11 is a relay, the positive switch 12 is an N-channel IGBT, and the resistor R1 is a cement ceramic resistor. The positive contact of the main positive contactor 11 is electrically connected to the power supply, the collector of the posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com