Anodes for lithium-ion battery cells, methods for making anodes, and batteries containing anodes

A lithium-ion battery and electrode technology, applied in the direction of electrode manufacturing, battery electrodes, electrode collector coating, etc., can solve problems such as insufficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] Other features, advantages and details of the invention will emerge from reading the following description of several embodiments of the invention, given as non-limiting illustrations in relation to the accompanying drawings, in which:

[0061] figure 1 is a graph illustrating the absorption spectrum measured by Fourier Transform Infrared Spectroscopy (abbreviated FTIR), showing the absorbance as a function of wavenumber for two elastomeric films composed of HNBR binder, one of which is a non-crosslinked "control" Thin films and another is crosslinked by thermal oxidation in the present invention.

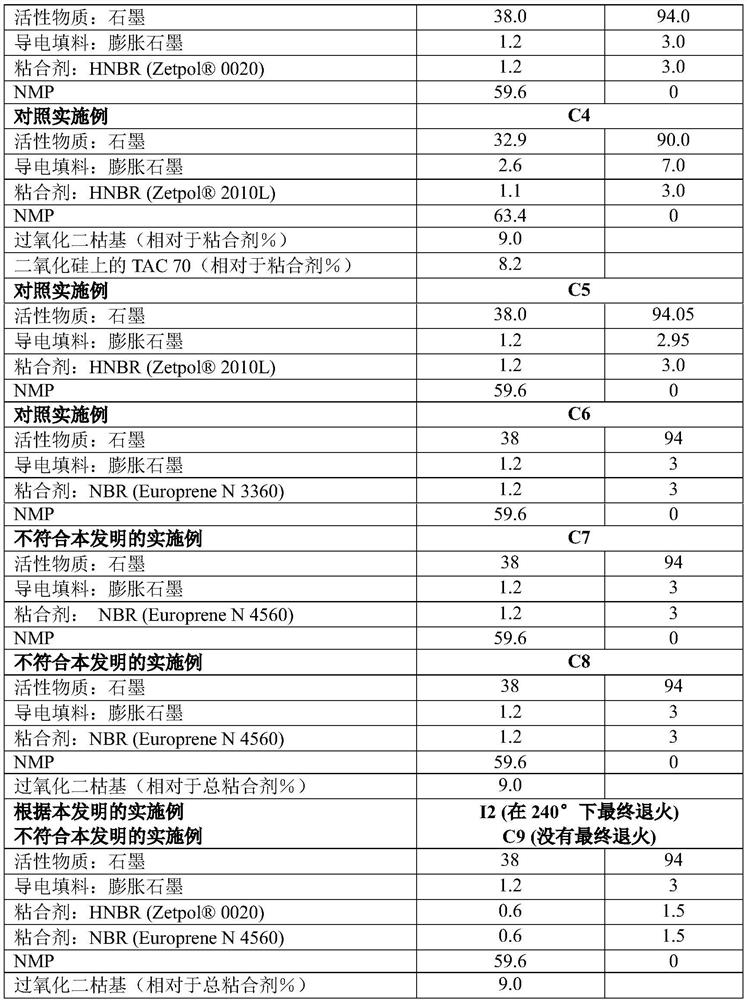

[0062] "Control" example not according to the invention, and lithium ions prepared by the liquid route according to the invention Examples of battery anodes:

[0063] All of the following examples use the following:

[0064] - as the active material, called C- Artificial graphite of L-SERIES (Timcal);

[0065] - as conductive filler, purified conductive expanded gra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com