Electric heating element deformation detecting control system

A detection control system, electric heating element technology, applied in the direction of electrical components, electric heating devices, measuring devices, etc., can solve the problems of swelling and rupture, deformation inspection, etc., and achieve the effect of isolating radioactive damage, simple operation, and reasonable conception

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

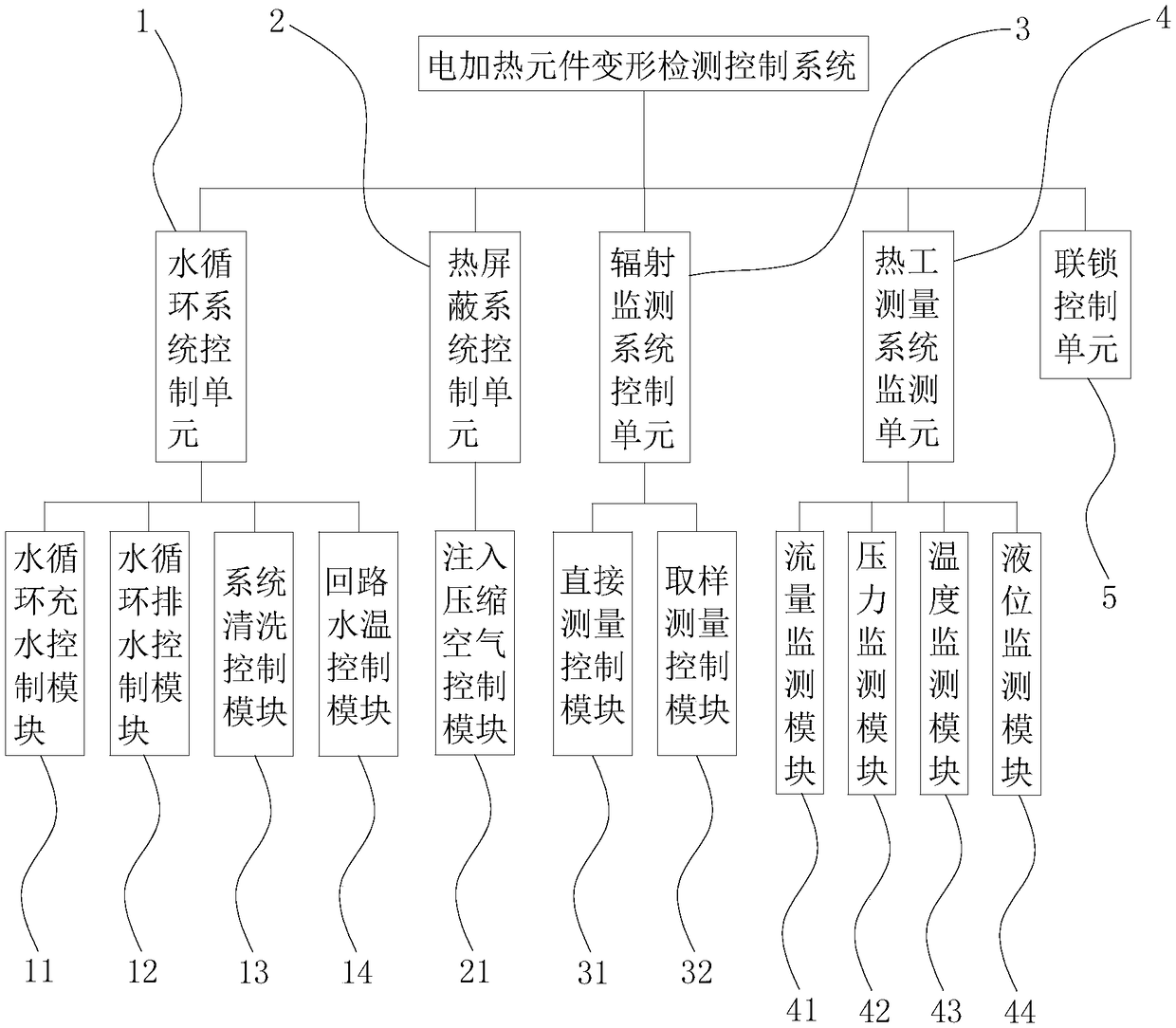

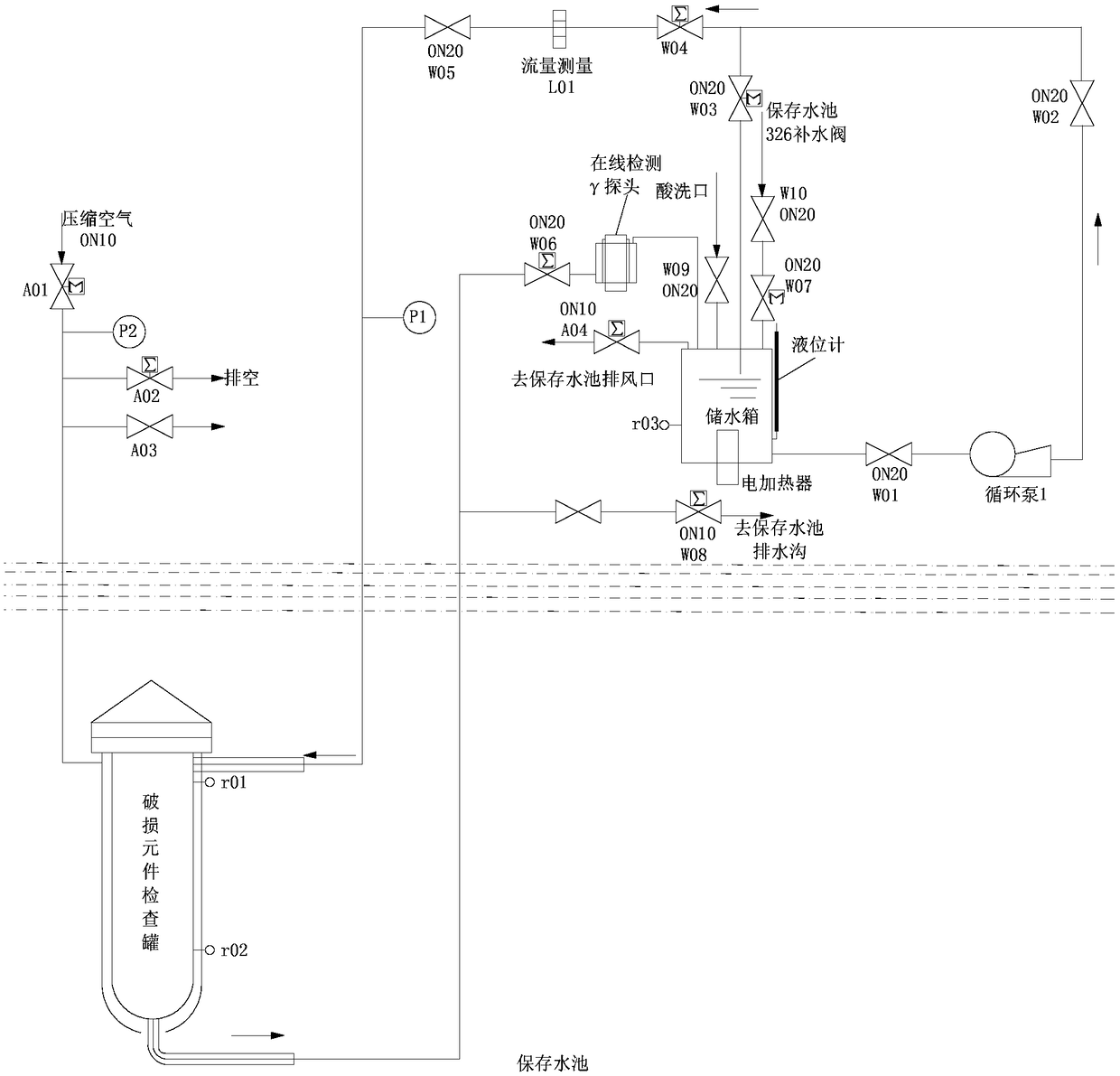

[0027] Such as figure 1 As shown, the electric heating element deformation detection control system of the present invention is used for real-time control of the electric heating element deformation detection system (such as image 3 shown) and includes a water circulation system control unit 1 , a heat shielding system control unit 2 , a radiation monitoring system control unit 3 , a thermal measurement system monitoring unit 4 and an interlock control unit 5 .

[0028] The water circulation system control unit 1 is used to control the water filling, drainage and cleaning of the water circulation system, and to heat and temperature control the circuit water of the water circulation system; wherein, the water circulation system control unit 1 includes a water circulation water filling control module 11, a water circulation system Drainage control module 12, system cleaning control module 13 and loop water temperature control module 14; the water circulation filling control mod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com