Down fluffing agent and preparation method thereof

A fluffy agent and down technology, which is applied in textiles and papermaking, fiber treatment, biochemical fiber treatment, etc., can solve the problems of down elasticity reduction, achieve unique smell, enhance luster, and improve bulkiness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

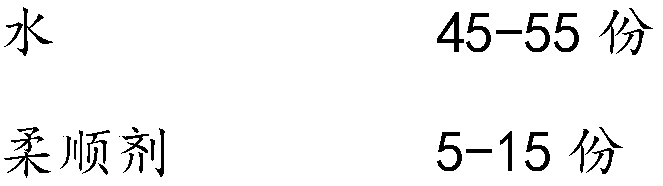

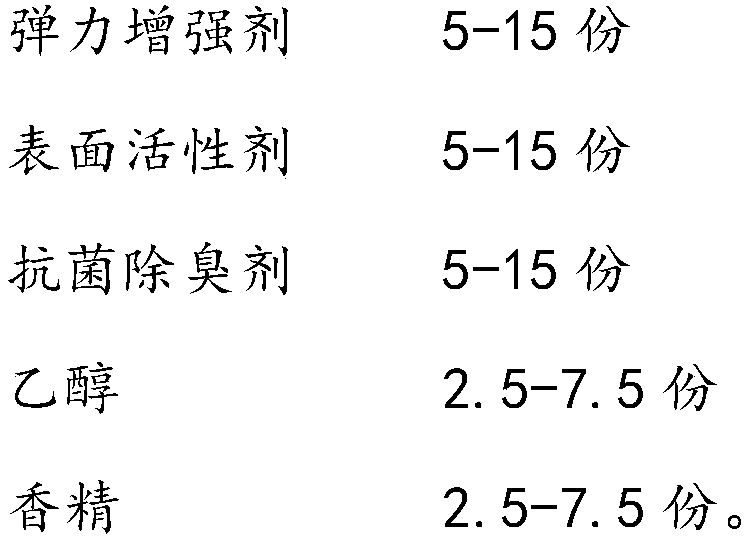

[0029] A down fluffing agent and a preparation method thereof, comprising the following raw materials in parts by weight: 45 parts of water, 5 parts of softener, 15 parts of elasticity enhancer, 5 parts of surfactant, 15 parts of antibacterial and deodorant parts, 7.5 parts of ethanol and 7.5 parts of essence, the softener is a mixture of fatty alcohol polyoxyethylene ether, bis-tallow acyl ethyl hydroxyethyl methyl ammonium methyl sulfate and polyethylene wax and fatty alcohol polyoxyethylene ether, double tallow The weight ratio of acyl ethyl hydroxyethyl methyl ammonium methyl sulfate and polyethylene wax is 3:5:2, and the elasticity enhancer is elastin, emulsifier, polyethylene glycol and polydimethylsiloxane. mixture, and the weight ratio of elastin, emulsifier, polyethylene glycol and polydimethylsiloxane is 1:2:6:1, and the surface modifier is isotridecyl ether, fatty acid methyl ester One or more of ethoxylate, AEO9, ethylene glycol stearate, phosphatidylcholine, trigl...

Embodiment 2

[0031] A down fluffing agent and a preparation method thereof, comprising the following raw materials in parts by weight: 50 parts of water, 10 parts of softeners, 10 parts of elasticity enhancers, 10 parts of surfactants, and 10 parts of antibacterial and deodorant agents. parts, 5 parts of ethanol and 5 parts of essence, the softener is a mixture of fatty alcohol polyoxyethylene ether, bis-tallow acyl ethyl hydroxyethyl methyl ammonium methyl sulfate and polyethylene wax, and fatty alcohol polyoxyethylene ether, double tallow The weight ratio of acyl ethyl hydroxyethyl methyl ammonium methyl sulfate and polyethylene wax is 3:5:2, and the elasticity enhancer is elastin, emulsifier, polyethylene glycol and polydimethylsiloxane. mixture, and the weight ratio of elastin, emulsifier, polyethylene glycol and polydimethylsiloxane is 1:2:6:1, and the surface modifier is isotridecyl ether, fatty acid methyl ester One or more of ethoxylate, AEO9, ethylene glycol stearate, phosphatidyl...

Embodiment 3

[0033] A down fluffing agent and a preparation method thereof, comprising the following raw materials in parts by weight: 55 parts of water, 15 parts of softener, 5 parts of elasticity enhancer, 15 parts of surfactant, 5 parts of antibacterial and deodorant parts, 2.5 parts of ethanol and 2.5 parts of essence, the softener is a mixture of fatty alcohol polyoxyethylene ether, bis-tallow ethyl hydroxyethyl methyl ammonium methyl sulfate and polyethylene wax and fatty alcohol polyoxyethylene ether, double tallow The weight ratio of acyl ethyl hydroxyethyl methyl ammonium methyl sulfate and polyethylene wax is 3:5:2, and the elasticity enhancer is elastin, emulsifier, polyethylene glycol and polydimethylsiloxane. mixture, and the weight ratio of elastin, emulsifier, polyethylene glycol and polydimethylsiloxane is 1:2:6:1, and the surface modifier is isotridecyl ether, fatty acid methyl ester One or more of ethoxylate, AEO9, ethylene glycol stearate, phosphatidylcholine, triglyceri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com