Production process of PP wood pulp composite wiping cloth

A production process and wiping cloth technology, which is applied in the direction of non-woven fabrics, textiles, and papermaking, can solve the problems of poor tear resistance, poor wear resistance, and low strength, and achieve soft hand feeling, good tear resistance, and high strength. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Example 1: Using 10g / ㎡ PP spunbond non-woven fabric as base fabric, using 75% Canadian wood pulp to loosen and grind wood pulp through chain plate machine, pulper, impurity remover, and mill , Made into white water with a solubility of 0.03%, pumped into the wire section of the paper machine through preliminary dehydration to form a wet fiber web into the spunlace machine, spread it flat on the PP cloth, and make the paper dry thickness 30g / ㎡. The pressures of the five spunlace heads in the puncturing process are respectively set to 35bar, 45bar, 65bar, 75bar, and 80bar, and the drying temperature is 115°C.

Embodiment 2

[0032] Example 2: Using 12g / ㎡ PP spunbond non-woven fabric as base fabric, using 75% Canadian wood pulp to loosen and grind the wood pulp through a chain plate machine, a pulper, a de-trash machine, and a mill , Made into white water with a solubility of 0.035%, pumped into the wire section of the paper machine through preliminary dehydration to form a wet fiber web into the spunlace machine, spread it on the PP cloth, and make the paper dry thickness 28g / ㎡. The pressure of the five spunlace heads in the puncturing process is set to 35bar, 45bar, 65bar, 75bar, 80bar, and the drying temperature is 120°C.

Embodiment 3

[0033] Example 3: Using 11g / ㎡ PP spunbond non-woven fabric as base fabric, using 75% Canadian wood pulp to loosen and grind wood pulp through chain plate machine, pulper, impurity remover, and mill , Made into white water with a solubility of 0.03%, pumped into the wire section of the paper machine through preliminary dehydration to form a wet fiber web into the spunlace machine, spread it flat on the PP cloth, and make the dry thickness of the paper 32g / ㎡. The pressure of the five spunlace heads in the puncturing process is set to 35bar, 45bar, 65bar, 75bar, 80bar, and the drying temperature is 120°C.

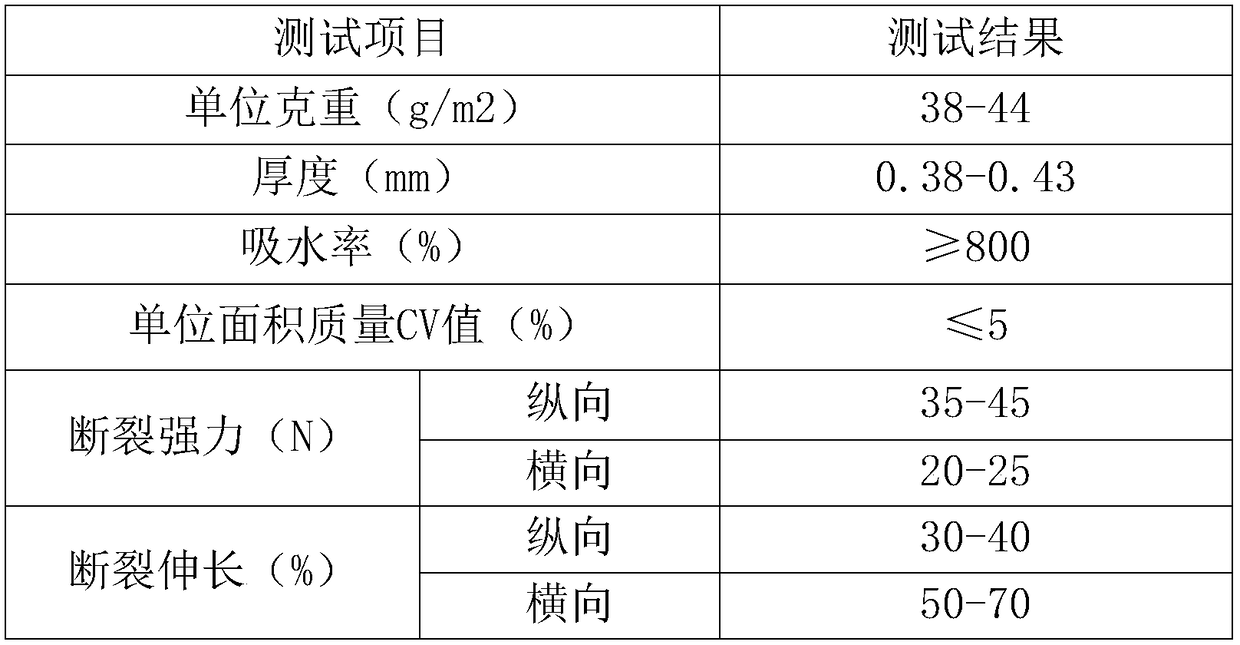

[0034] After testing, the technical indicators of the composite non-woven fabric prepared by the process of the present invention are shown in the following table:

[0035]

[0036] It can be known from the above test results that the composite non-woven fabric prepared by the process of the present invention has good moisture absorption, high strength, good tear resistance and goo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com