High-light anti-fouling wear-proof water-based paint special for PVC surface decoration and preparation method thereof

A surface decoration, water-based coating technology, applied in anti-fouling/underwater coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problems of poor anti-fouling and wear resistance, weak decorative ability, low adhesion, etc. The effect of strong adhesion, improved product utilization, and good blocking resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The raw materials and reagents for the preparation of the emulsion described in this example mainly include: polycarbonate diol from Jining Huakai Resin Co., Ltd.; isophorone diisocyanate from Wuxi Dongrun Electronic Material Technology Co., Ltd.; dimethylol butyric acid From Anhui Zhongen Chemical Co., Ltd.; trimethylolpropane, dibutyltin dilaurate, and triethylamine from Guangdong Wengjiang Chemical Reagent Co., Ltd.; ethylenediamine from Shandong West Asia Chemical Industry Co., Ltd.

[0032] The water-based paint of this embodiment is produced in two steps. The first step is to prepare polycarbonate-based water-based polyurethane emulsion; the second step is to prepare the water-based paint. The specific preparation method is as follows:

[0033] The first step, the preparation of polycarbonate water-based polyurethane emulsion

[0034] Based on the total mass of monomers, weigh 62% polycarbonate diol, 31% isophorone diisocyanate, 1% trimethylolpropane and 0.1% dib...

Embodiment 2

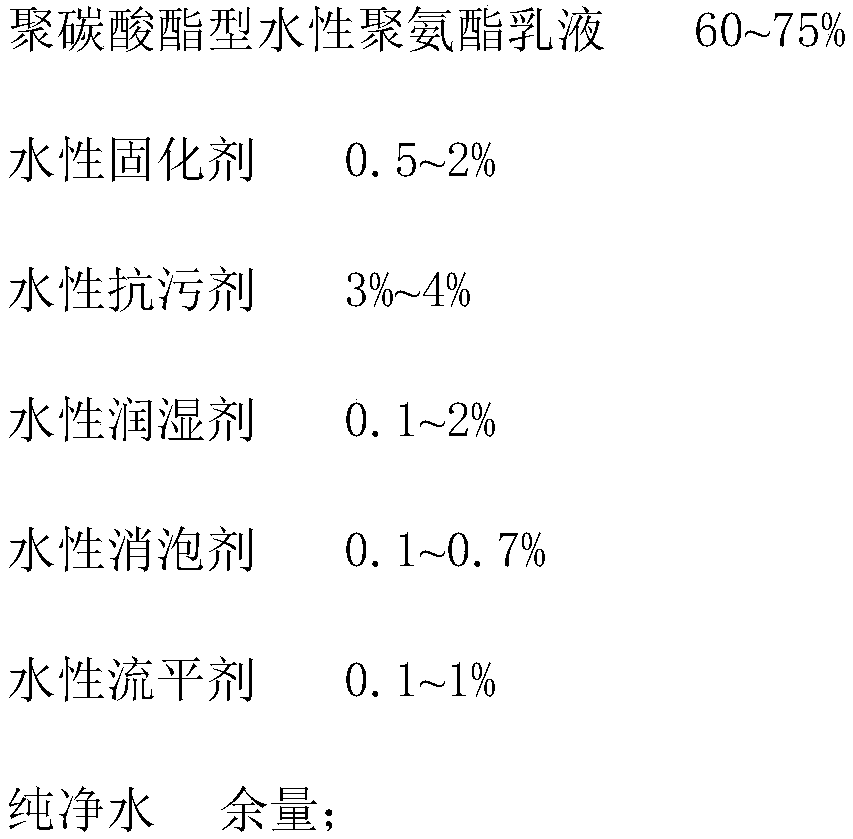

[0048] Formula is as follows (by weight fraction ratio):

[0049] Homemade polycarbonate-based water-based polyurethane emulsion 75%;

[0050] Water-based antifouling agent 3%, polydimethylsiloxane emulsion containing hydroxyl functional groups, model Germany TEGO 5100N, from Xiamen Baiguiquan Trading Co., Ltd.;

[0051] Water-based curing agent 0.8%, amine-based water-based resin crosslinking agent, model D-04, from Xiamen Baiguiquan Trading Co., Ltd.;

[0052] Water-based wetting agent 1%, high-performance ethoxylated nonionic super wetting agent, model HH-607, from Taizhou Henghai Chemical Co., Ltd.;

[0053] Water-based defoamer 0.6%, water-based polyurethane defoamer, model F-828, from Xiamen Baiguiquan Trading Co., Ltd.;

[0054] Water-based leveling agent 0.6%, polyether modified polydimethylsiloxane solution, model BYK346 in Germany, from Xiamen Baiguiquan Trading Co., Ltd.;

[0055] Pure water balance.

[0056] Weigh the raw materials according to the weight fract...

Embodiment 3

[0060] Formula is as follows (by weight fraction ratio):

[0061] Homemade polycarbonate-based water-based polyurethane emulsion 70%;

[0062] Water-based antifouling agent 3%, polydimethylsiloxane emulsion containing hydroxyl functional groups, model Germany TEGO 5100N, from Xiamen Baiguiquan Trading Co., Ltd.;

[0063] Water-based curing agent 1.3%, amine-based water-based resin crosslinking agent, model D-04, from Xiamen Baiguiquan Trading Co., Ltd.;

[0064] Water-based wetting agent 1.5%, high-performance ethoxylated nonionic super wetting agent, model HH-607, from Taizhou Henghai Chemical Co., Ltd.;

[0065] Water-based defoamer 0.6%, water-based polyurethane defoamer, model F-828, from Xiamen Baiguiquan Trading Co., Ltd.;

[0066] Water-based leveling agent 0.6%, polyether modified polydimethylsiloxane solution, model BYK346 in Germany, from Xiamen Baiguiquan Trading Co., Ltd.;

[0067] Pure water balance.

[0068] Weigh the raw materials according to the weight fra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| gloss | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com