Wall material protecting film and preparation method thereof

A protective film and wall material technology, applied in the field of wall material protective film and its preparation, can solve the problems of user health hazards, decoration wall materials containing peculiar smell, etc., and achieve the effects of beautifying the environment, purifying indoor air, and having a good hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

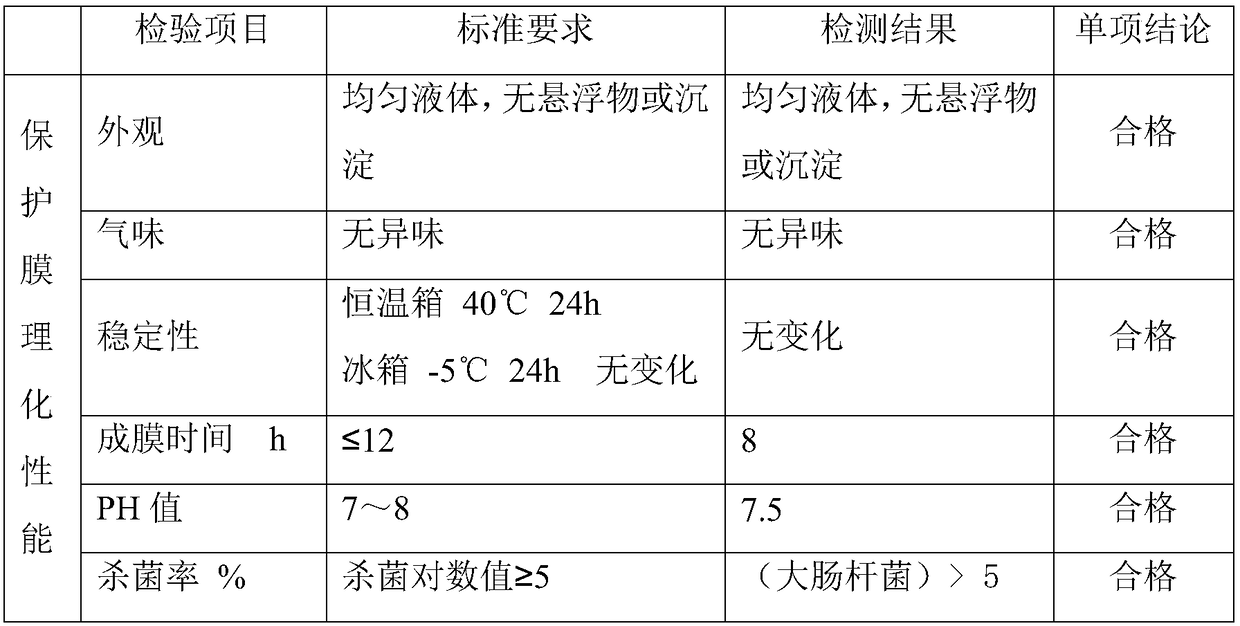

Image

Examples

Embodiment 1

[0023] The application provides a wall material protective film, which is composed of the following raw materials in parts by weight: emulsion 250, nano photocatalyst 30, formaldehyde scavenger 15, active nano silver ions 70, and some deionized water.

[0024] Optionally, the emulsion is an acrylate styrene emulsion polymer.

[0025] Optionally, the nano photocatalyst is titanium dioxide.

[0026] Optionally, the formaldehyde scavenger is imidazolidinone.

[0027] A preparation method of a wall material protective film, said preparation method comprising the steps of:

[0028] Step 1: After completely dissolving the emulsion, nano-photocatalyst, formaldehyde scavenger, and active nano-silver ions with deionized water, add them to the reaction tank in sequence according to the proportion;

[0029] Step 2: Start the reaction tank, and stir for 30-45 minutes at room temperature at 300-500 rpm.

Embodiment 2

[0031] The application provides a wall material protective film, which is composed of the following raw materials in parts by weight: emulsion 280, nano photocatalyst 35, formaldehyde scavenger 25, active nano silver ions 90, and some deionized water.

[0032] Optionally, the emulsion is an acrylate styrene emulsion polymer.

[0033] Optionally, the nano photocatalyst is titanium dioxide.

[0034] Optionally, the formaldehyde scavenger is imidazolidinone.

[0035] A preparation method of a wall material protective film, said preparation method comprising the steps of:

[0036] Step 1: After completely dissolving the emulsion, nano-photocatalyst, formaldehyde scavenger, and active nano-silver ions with deionized water, add them to the reaction tank in sequence according to the proportion;

[0037] Step 2: Start the reaction tank, and stir for 30-45 minutes at room temperature at 300-500 rpm.

Embodiment 3

[0039] The application provides a wall material protective film, which is composed of the following raw materials in parts by weight: emulsion 300, nano photocatalyst 40, formaldehyde scavenger 130, active nano silver ions 100, and some deionized water.

[0040] Optionally, the emulsion is an acrylate styrene emulsion polymer.

[0041] Optionally, the nano photocatalyst is titanium dioxide.

[0042] Optionally, the formaldehyde scavenger is imidazolidinone.

[0043] A preparation method of a wall material protective film, said preparation method comprising the steps of:

[0044] Step 1: After completely dissolving the emulsion, nano-photocatalyst, formaldehyde scavenger, and active nano-silver ions with deionized water, add them to the reaction tank in sequence according to the proportion;

[0045] Step 2: Start the reaction tank, and stir for 30-45 minutes at room temperature at 300-500 rpm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com