A kind of building molding material and method thereof produced by using silicon thermal method magnesium smelting waste slag as raw material

A technology of magnesium smelting waste slag and molding materials, which is applied in the field of building molding materials, can solve problems such as high production costs, large equipment investment, and complex production processes, and achieve the effects of reducing emissions, reducing molding pressure, and obvious economic and environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

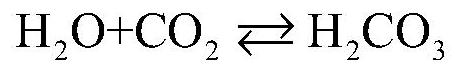

Method used

Image

Examples

Embodiment 1

[0061] A kind of method of the present invention is that the waste slag of magnesium smelting of silicothermal method is raw material production building molding material, and its implementation steps are as follows,

[0062] Step 1, raw material preparation;

[0063] Take the non-moisture-absorbing magnesium smelting reduction waste slag after natural cooling and pulverization, sieve it with a 10-mesh sieve, manually roll all the sieve to 90 mesh, and evenly blend with the powdered sieve to prepare the Powdered magnesium slag raw material 10kg;

[0064] Step 2, stir and hydrate;

[0065] Pour the blended powdered magnesium slag raw material into the container, add water while stirring and mixing, until it can be kneaded into a block with hands, and the amount of water added is 3kg;

[0066] Step 3, compression molding;

[0067] Make a steel mold according to the standard brick size, take the raw materials after mixing and hydration, manually fill them into the mold, pound ...

Embodiment 2

[0072] Carry out according to the steps of Example 1, wherein use 30 mesh sieves to sieve the non-moisture-absorbing magnesium smelting reduction waste slag, and all the oversieves are manually rolled to 120 mesh to obtain 2.1 kg of magnesium slag raw materials; when proceeding to step 2 , the amount of water added is 0.42kg; when it comes to step 3, use a press to press the pressure of 1MPa to form it, and then get another piece of magnesia slag brick after demoulding; step 4 carbonization maintenance is carried out under the conditions of 0.15MPa and 30°C, and continuous maintenance After 6 hours, the magnesia slag brick was taken out, and the compressive strength of the magnesia slag brick was tested to be 40MPa, and the flexural strength was 12MPa.

Embodiment 3

[0074] Carry out according to the steps of Example 1, wherein use 90 mesh sieves to sieve the non-moisture-absorbing magnesium smelting reduction waste slag, and manually roll the oversize to 150 mesh to obtain 3.0 kg of magnesium slag raw material; when proceeding to step 2 , the amount of water added is 0.3kg; when it comes to step 3, use a press to press the pressure of 10MPa to form, and then get a magnesia slag brick after demoulding; step 4 carbonization maintenance is carried out under the conditions of 0.2MPa and 60°C, and continuous maintenance After 8 hours, the magnesia slag brick was taken out, and the compressive strength of the magnesia slag brick was tested to be 55MPa, and the flexural strength was 17MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com