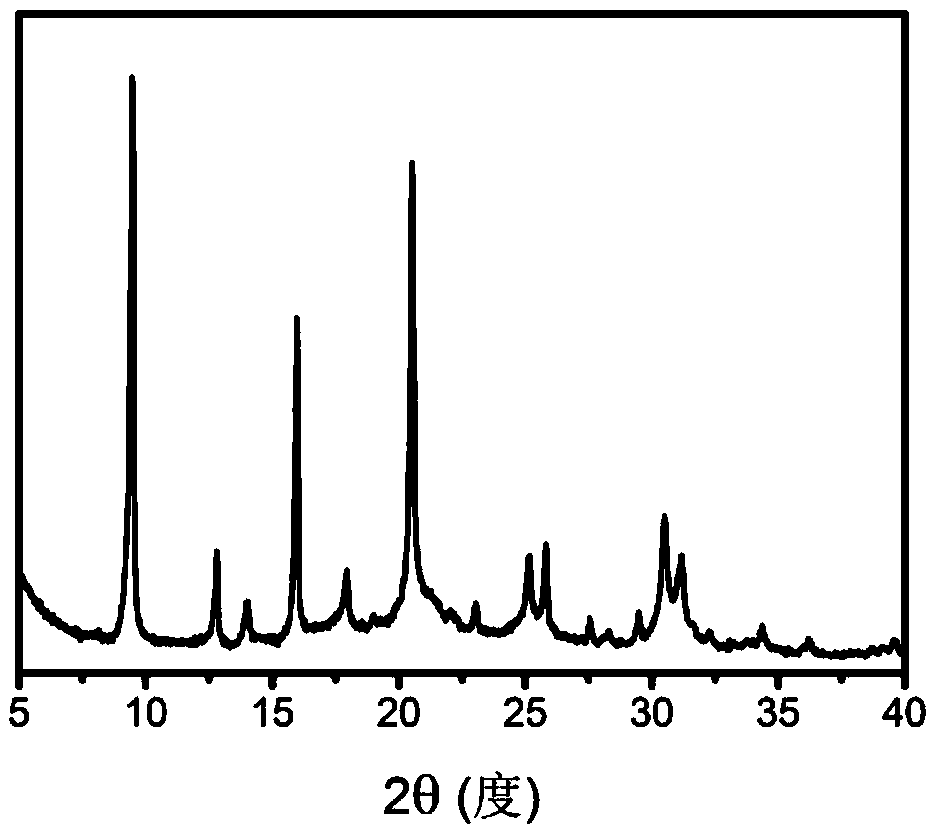

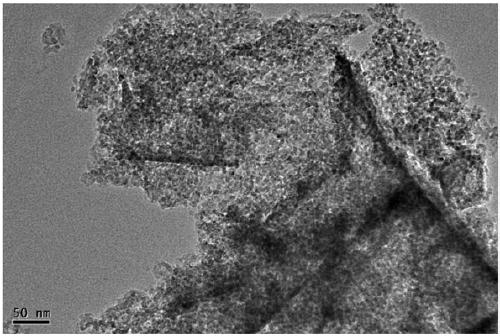

Two-dimensional ultra-thin Me-SAPO-34 molecular sieve thin-sheet material and preparation method thereof

A me-sapo-34 and molecular sieve technology, which is applied in the field of two-dimensional ultra-thin Me-SAPO-34 molecular sieve sheet material and its preparation, achieves the effects of less environmental pollution, low cost and universal method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Take 0.500 g of aluminum phosphate nanovolume powder, add 0.150 g of tetraethyl orthosilicate, 0.450 g of ethanol and 0.025 g of ferric nitrate, stir at room temperature into a uniform paste, and let it stand for 24 hours; after that, add 0.150 g of tetraethyl hydrogen Ammonium oxide (25%) solution, stirred into a uniform paste, and left for 24 hours; after that, it was transferred to a solution that added 0.125 g of water, 0.300 g of tetraethylammonium hydroxide (25%) and 0.500 g of triethylammonium hydroxide. In the polytetrafluoroethylene lining of the hydrothermal kettle of amine, seal; after that, hydrothermal at 160 ℃ for 72 hours; after that, naturally cool to room temperature, filter to obtain the precipitate, and use water and absolute ethanol to wash the precipitate for many times, at 60 °C for 24 hours to obtain a dry yellow powder; after that, the obtained white powder was put into a muffle furnace, and the temperature was raised from room temperature to 550 ...

Embodiment 2

[0038] Take 1.000 grams of aluminum phosphate nanovolume powder, add 0.350 grams of tetraethyl orthosilicate, 0.850 grams of ethanol and 0.150 grams of ferric nitrate, stir at room temperature into a uniform paste, and let it stand for 24 hours; after that, add 0.360 grams of tetramethylhydrogen Ammonium oxide (25%) solution, stirred into a uniform paste, and left for 24 hours; after that, it was transferred to a solution that added 0.325 g of water, 0.750 g of tetramethylammonium hydroxide (25%) and 1.500 g of triethylammonium hydroxide. In the polytetrafluoroethylene lining of the hydrothermal kettle of amine, seal it; after that, heat it in water at 180°C for 36 hours; after that, cool it naturally to room temperature, filter to obtain the precipitate, and wash the precipitate with water and absolute ethanol several times, at 60 °C for 24 hours to obtain a dry yellow powder; after that, the obtained white powder was put into a muffle furnace, and the temperature was raised f...

Embodiment 3

[0041] Take 2.000 grams of aluminum phosphate nanovolume powder, add 0.800 grams of tetraethyl orthosilicate, 1.600 grams of ethanol and 0.240 grams of cobalt nitrate, stir into a uniform paste at room temperature, and let it stand for 24 hours; after that, add 0.800 grams of tetraethylhydrogen Ammonium oxide (25%) solution, stirred into a uniform paste, and left for 24 hours; after that, it was transferred to a solution of 0.800 g of water, 1.600 g of tetraethylammonium hydroxide (25%) and 3.200 g of triethylammonium hydroxide. In the polytetrafluoroethylene liner of the hydrothermal kettle of amine, seal; after that, hydrothermal at 180 ℃ for 48 hours; after that, naturally cool to room temperature, filter to obtain the precipitate, and use water and absolute ethanol to wash the precipitate for many times, at 60 °C for 24 hours to obtain a dry purple powder; after that, the obtained white powder was put into a muffle furnace, and the temperature was raised from room temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com