Method for preparing high-quality graphene quantum dot or large-lamella graphene oxide

A graphene quantum dot, high-quality technology, applied in the direction of graphene, single-layer graphene, chemical instruments and methods, etc., can solve the problems of complex operation and low strategy efficiency, achieve good water solubility, uniform size, and improve peeling efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

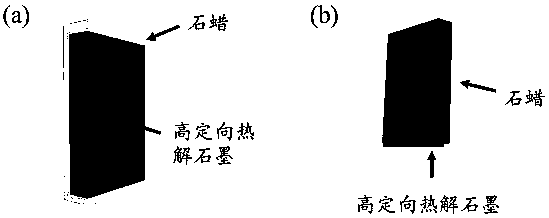

[0029] A method for preparing graphene quantum dots, the steps are as follows:

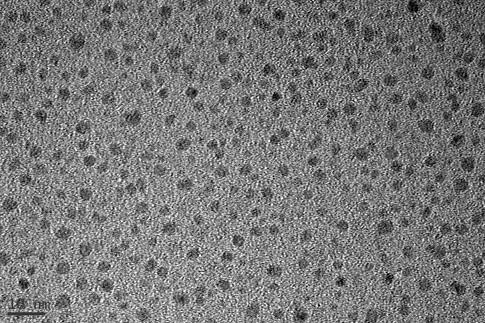

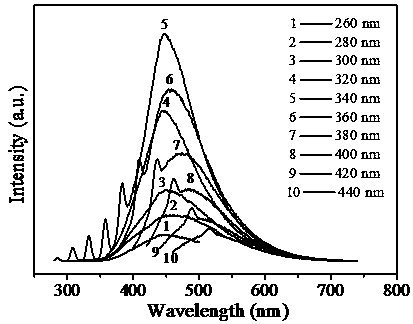

[0030]Highly oriented and regular highly oriented pyrolytic graphite is partially coated with paraffin to expose the (002) crystal plane, which is used as an anode. Under the condition of applying a constant voltage of 3V, the electrochemical reaction was carried out in a 10 mol / L NaOH alkaline electrolyte solution to obtain graphene quantum dots dispersed in an alkaline electrolyte aqueous solution. The mixed solution of gained quantum dots and electrolyte is diluted, and the quantum dot solution is neutralized with 0.1mol / L dilute hydrochloric acid solution, and the solution is dialyzed for 3 days in a dialysis bag with a molecular weight cut-off of 3000 Da, and the salt in the solution is All removed, namely obtain the graphene quantum dot aqueous solution with uniform size distribution. The graphene quantum dot aqueous solution after dialysis is freeze-dried to obtain blue fluorescent graphen...

Embodiment 2

[0033] A method for preparing graphene oxide, the steps are as follows:

[0034] Pyrolytic graphite was partially coated with paraffin to expose the (002) crystal plane, which was used as the anode. Under the condition of external constant voltage 4V, in 0.1mol / L H 2 SO 4 The electrochemical reaction is carried out in the electrolyte solution to obtain graphene oxide dispersed in the acidic electrolyte solution. The electrolyte solution of the obtained product was vacuum filtered at 0.05MPa / 1 minute, washed with deionized water several times, and freeze-dried (freezing temperature: -50°C, drying temperature: 0°C, drying vacuum: 1Pa, drying time: 48 hours) After that, high-quality graphene oxide is obtained.

Embodiment 3

[0036] A method for preparing graphene oxide, the steps are as follows:

[0037] Highly oriented and regular highly oriented pyrolytic graphite is partially coated with paraffin to expose the (002) crystal plane, which is used as an anode. Under the condition of alternating voltage of 2V-5V, at 0.1mol / L Na 2 SO 4 The electrochemical reaction is carried out in the electrolyte solution to obtain graphene oxide dispersed in the acidic electrolyte solution. The resulting product electrolyte solution was vacuum filtered at 0.2MPa / 120 minutes, washed with deionized water several times, and freeze-dried (freezing temperature: liquid nitrogen temperature, drying temperature: 20°C, drying vacuum: 14Pa, drying time: 1 hour) After that, high-quality graphene oxide is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com