Prefabricated box girder steel bar binding and positioning jig frame

A technology for tying steel bars and positioning tires, which is used in manufacturing tools, ceramic molding machines, building structures, etc., can solve the problems of time-consuming and laborious handling of semi-finished steel bars, restricting construction progress by quality and speed, and low qualification rate of steel protective layers. It is convenient for multi-position lifting and adjustment, improving convenience, and the effect of convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

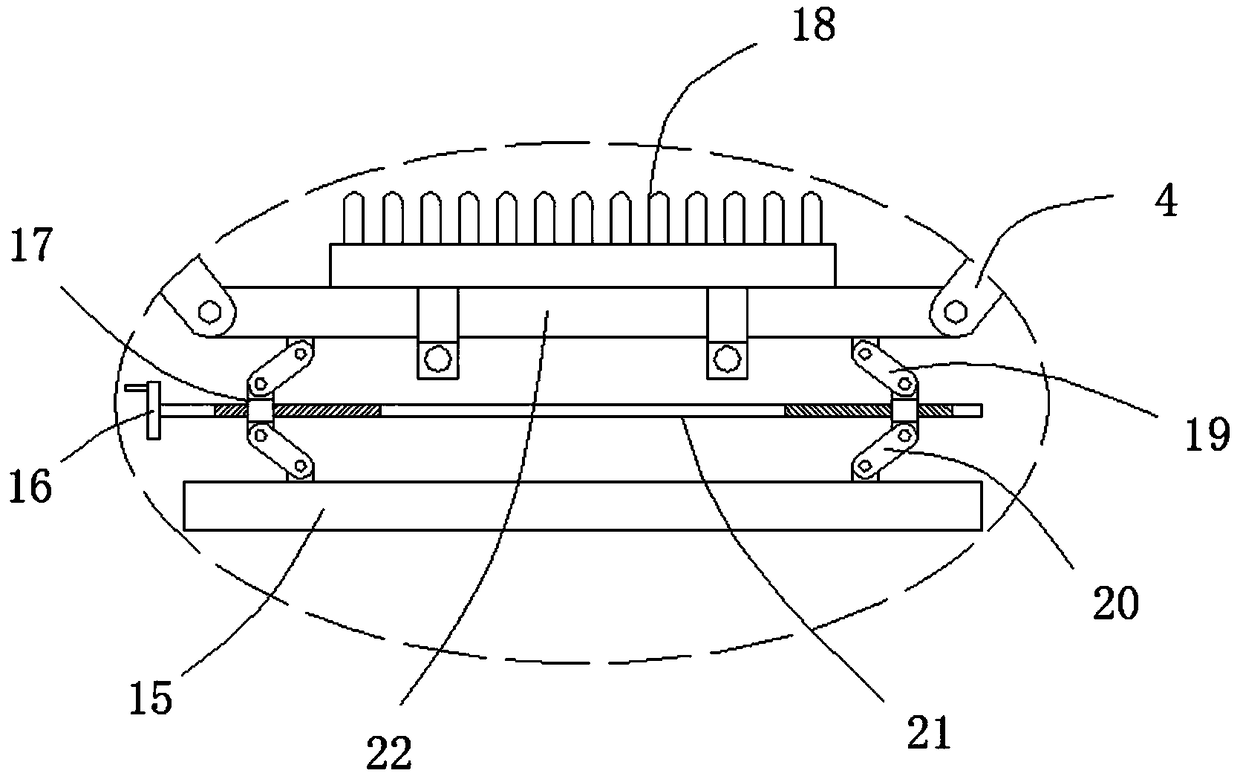

[0025] refer to Figure 1-6 , a prefabricated box girder reinforcement binding positioning tire frame, including a first bottom plate 1 and a second bottom plate 15, the first bottom plate 1 is provided with two, and the top of the first bottom plate 1 is welded with a plurality of equidistantly arranged support columns 2, The top of the support column 2 is fixed with a fixed bar 10, the top of the fixed bar 10 is provided with a rolling groove, the top of the fixed bar 10 is provided with a moving block 12, the bottom of the moving block 12 is equipped with a roller 11, and the roller 11 is rolled and installed in the rolling groove , a first bushing 7 is arranged b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com