A composition for carbon catalytic hydrogenation to methane

A composition, a technology for producing methane, applied in the directions of chemical/physical processes, physical/chemical process catalysts, chemical instruments and methods, etc., to achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

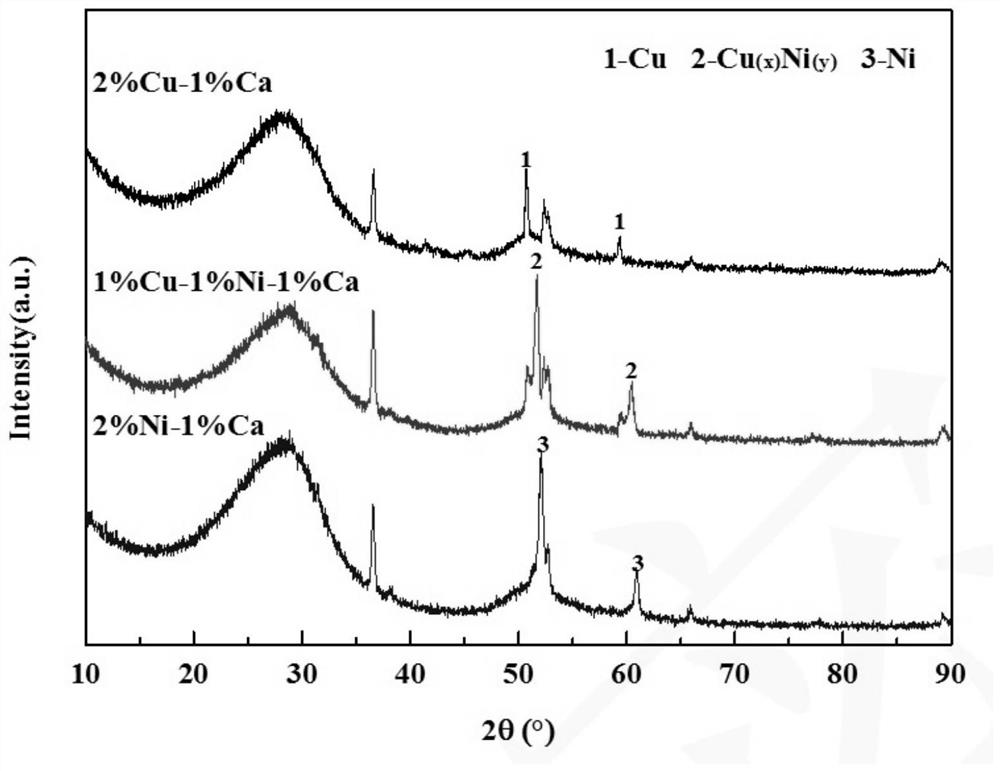

Method used

Image

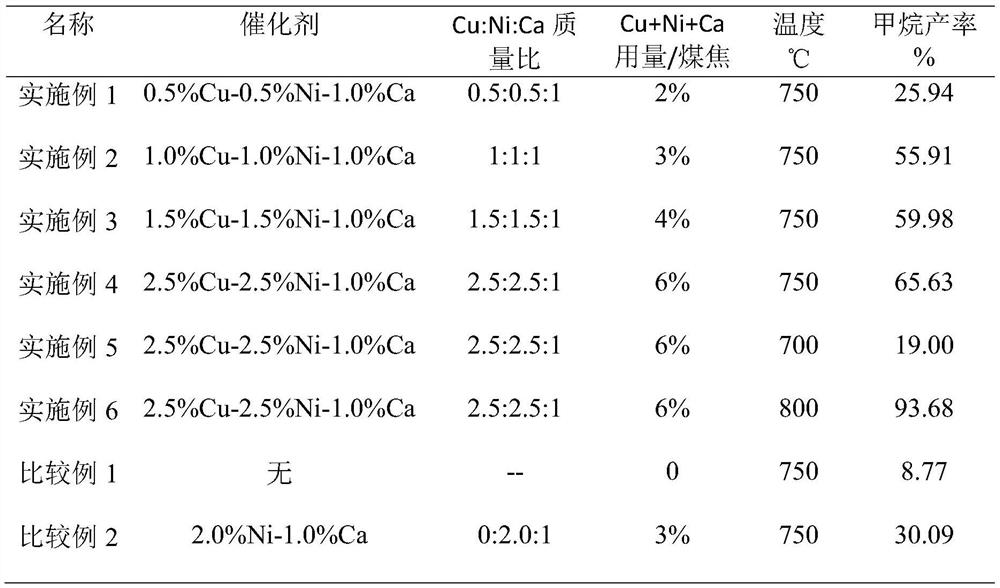

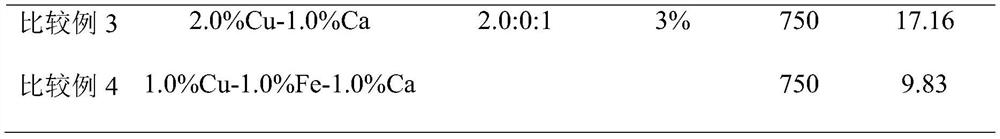

Examples

Embodiment 1

[0029] Weigh 0.0190g of Cu(NO 3 ) 2 ·3H 2 O, 0.0248g of Ni(NO 3 ) 2 ·6H 2 O, 0.0589g Ca(NO 3 ) 2 ·4H 2 O Mix and place in a small beaker, add 0.7ml of deionized water to obtain a mixed solution evenly by ultrasonication, weigh 1g of 20-40 mesh coal char into the mixed solution, impregnate with ultrasonic for 2 hours, and dry in a drying oven at 105°C for 24 hours , to be cooled to room temperature and stored in a desiccator for later use.

[0030] Put the above dried coal char into the fixed bed reactor, and carry out gasification reaction under the conditions of reaction temperature 750°C, hydrogen pressure 2MPa, hydrogen flow rate 50ml / min to obtain product methane.

Embodiment 2

[0032] Weigh 0.0380g of Cu(NO 3 ) 2 ·3H 2 O, 0.0495g of Ni(NO 3 ) 2 ·6H 2 O, 0.0589g Ca(NO 3 ) 2 ·4H 2 O Mix and place in a small beaker, add 0.7ml of deionized water to obtain a mixed solution evenly by ultrasonication, weigh 1g of 20-40 mesh coal char into the mixed solution, impregnate with ultrasonic for 2 hours, and dry in a drying oven at 105°C for 24 hours , to be cooled to room temperature and stored in a desiccator for later use.

[0033] Put the above dried coal char into the fixed bed reactor, and carry out gasification reaction under the conditions of reaction temperature 750°C, hydrogen pressure 2MPa, hydrogen flow rate 50ml / min to obtain product methane.

Embodiment 3

[0035] Weigh 0.0570g of Cu(NO 3 ) 2 ·3H 2 O, 0.0743g Ni(NO 3 ) 2 ·6H 2 O, 0.0589g Ca(NO 3 ) 2 ·4H 2 O Mix and place in a small beaker, add 0.7ml of deionized water to obtain a mixed solution evenly by ultrasonication, weigh 1g of 20-40 mesh coal char into the mixed solution, impregnate with ultrasonic for 2 hours, and dry in a drying oven at 105°C for 24 hours , to be cooled to room temperature and stored in a desiccator for later use.

[0036] Put the above dried coal char into the fixed bed reactor, and carry out gasification reaction under the conditions of reaction temperature 750°C, hydrogen pressure 2MPa, hydrogen flow rate 50ml / min to obtain product methane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com