High-elastic double-density in-mold foamed rubber sole and production process thereof

A technology of foam rubber and double density, which is applied to shoe soles, footwear, footwear, etc., can solve the problems of insufficient elasticity, high cost, time-consuming, etc., and achieve the effect of increasing elasticity, high bonding strength, and good composite effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

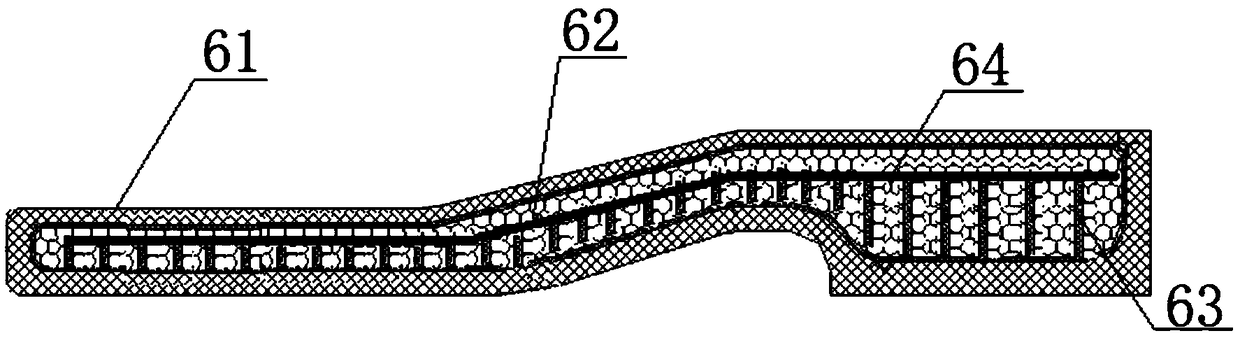

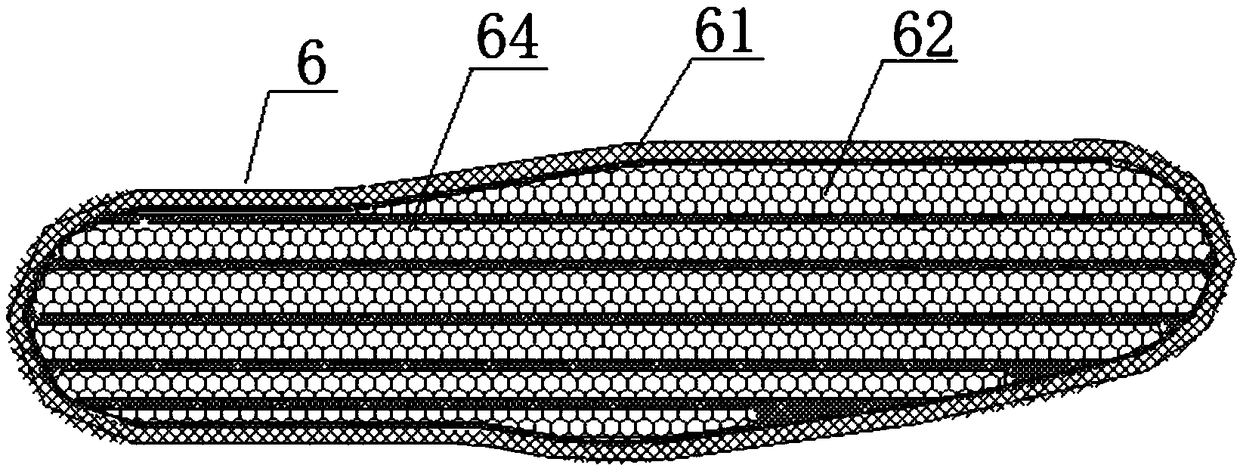

[0055] The high-elasticity dual-density in-mold foamed rubber sole of this embodiment, such as figure 1 , 2As shown in the figure, it includes a high-density outer layer 61 and a low-density inner layer 62, and is an integrated structure that is ejected from the same mold; the high-density outer layer 61 and the low-density inner layer 62 are made of high-density rubber compound and low-density material respectively. The low-density inner layer 62 is also embedded with a vertical spring support 63 evenly.

[0056] The component formula of the low-density rubber compound and its respective parts by weight include: 40-50 of solution-polymerized styrene-butadiene rubber, 15-25 of natural rubber, 5-10 of fumed silica, 7-12 of isoprene rubber, and 7-12 of naphthenic oil. 11. Stearic acid 0.5-1.5, zinc oxide 1-5, 120 resin 3-8, dicumyl peroxide 0.1-0.3; high-density sizing material component formula and their respective weight parts include: compound rubber 35-45 , reclaimed rubbe...

Embodiment 2

[0060] The high-elasticity dual-density in-mold foamed rubber sole of the present embodiment has the same basic structure as that of Embodiment 1, and the improvements are as follows: image 3 , 4 As shown, the compression molding and foaming vulcanization device 3 includes a mold clamping cylinder 31, an upper mold half 33, a lower mold half 34, a mold inner core 35, a mold inner core 2 36 and a mold core rotating cylinder 39; the lower half mold The mold 34 is fixed on the die vulcanization table 5, and the upper mold half 33 is matched with the upper mold half 33 directly above the lower mold half 34. The upper mold half 33 is detachably connected to the mold clamping cylinder 31; the mold clamping cylinder 31 passes through the fixing frame Fixed; the mold inner core 1 35 and the mold inner core 2 36 have the same shape and different specifications, and the tail ends of the two are opposite to each other, and both are detachable and fixed with the mold core conversion brac...

Embodiment 3

[0079] The high-elasticity double-density in-mold foamed rubber sole of the present embodiment has the same basic structure as that of embodiment 2, and the improvement is as follows: figure 1 , 2 As shown, the end of the spring support 63 is fixed with a connecting plate 64, which is convenient for the presetting and fixing of the spring support 63 in the mold synchronously. Presetting the spring support 63 before the rubber is vulcanized can effectively improve the combination of the spring support 63 and the rubber. Strength, the rubber can be embedded in the gap of the spring, can fluctuate synchronously with the elasticity of the spring, and play the role of skeleton support. The same mold is produced, the bonding strength of the spring and the rubber is high, and the composite effect is good. The elasticity of the spring can be selected to be consistent with the elasticity of the low-density rubber layer. In order to strengthen the support strength of the low-density inn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent density | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com