A high-elastic wear-resistant double-density in-mold foam rubber tire and its manufacturing process

A foamed rubber, high-density technology, applied in the field of rubber product technology, can solve the problems of insufficient elasticity, high cost, energy consumption, etc., and achieve the effect of increasing elasticity, high bonding strength, and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

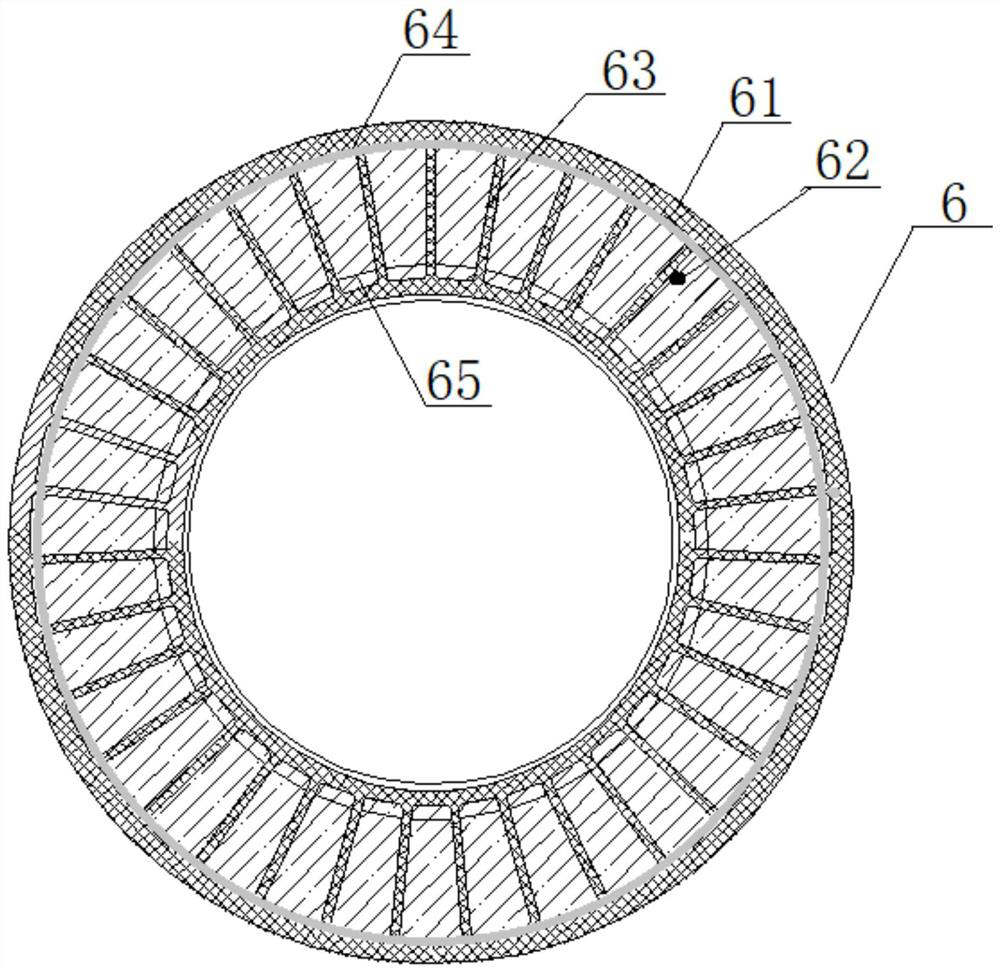

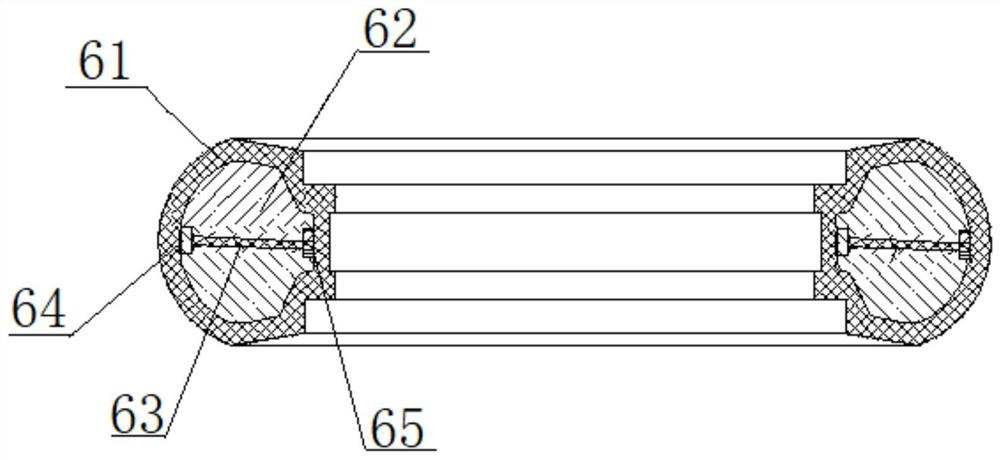

[0056] The high-elastic wear-resisting dual-density foamed rubber tire in the mold of the present embodiment, as figure 1 , 2As shown, it includes a high-density outer layer 61 and a low-density inner layer 62, which is an integrated structure that is released from the same mold; the materials of the high-density outer layer 61 and the low-density inner layer 62 are high-density rubber and low-density rubber, respectively. Rubber material, the low-density inner layer 62 is also evenly embedded with spring supports 63 in a radial state, which play a role in skeleton support, similar to steel bars in concrete, and the spring elasticity can be selected to be consistent with the elasticity of low-density rubber to strengthen The support strength of the low-density inner layer slows down the elastic fatigue attenuation caused by frequent deformation of the low-density inner layer.

[0057] The formula of high-density rubber components and their respective parts by weight include: ...

Embodiment 2

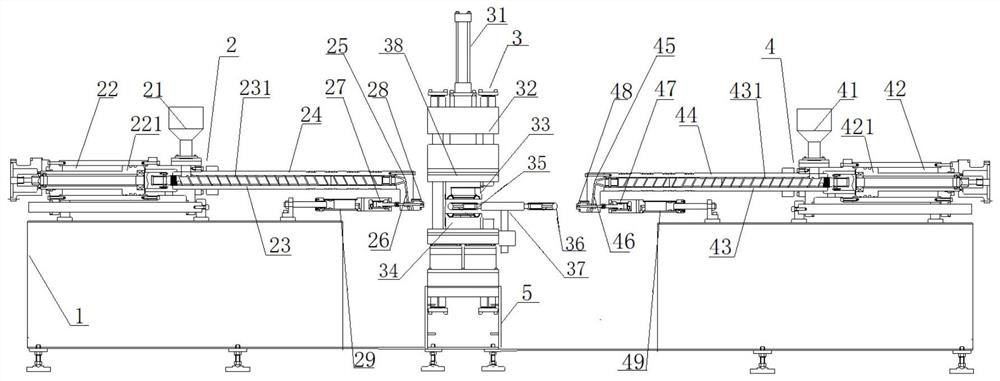

[0061] The basic structure of the high-elastic and wear-resistant double-density in-mold foam rubber tire of this embodiment is the same as that of Embodiment 1, and the improvement is that connecting plates are fixed at both ends of the spring support to facilitate the synchronization of the spring support in the mold. and fixed, the preset spring support is carried out before rubber vulcanization, which are the outer ring connecting plate 64 and the inner ring connecting plate 65; the outer ring connecting plate 64 and the inner ring connecting plate 65 are both tightly against the height The density of the outer layer is 61, and it can be designed as a curved plate that fits the shape of the outer or inner ring of the tire, which can effectively improve the bonding strength between the spring support and the rubber. The rubber can be embedded in the spring gap and can recover synchronously with the spring elasticity; image 3 , 4 As shown, the compression molding and foam v...

Embodiment 3

[0080] The high-elastic and wear-resistant dual-density in-mold foam rubber tire of this embodiment has the same basic structure as that of Embodiment 2;

[0081] The high-elastic and wear-resistant dual-density in-mold foam rubber tire of the present embodiment, the low-density rubber component formula and its respective parts by weight include: 39 parts of composite rubber, 35 parts of regenerated rubber, 5 parts of styrene-butadiene rubber, and 5 parts of natural rubber. Parts; 8 parts of butadiene rubber, 5 parts of 120 resin, 12 parts of carbon black, 5 parts of naphthenic oil, 0.7 parts of stearic acid, 3 parts of zinc oxide, 1.3 parts of composite accelerator, 2.5 parts of composite anti-aging agent, and composite vulcanizing agent 2.1 parts. Composite rubber is the composition of naphthenic oil, butyl rubber, butadiene rubber, natural rubber, white carbon black, black carbon black N330, stearic acid, zinc oxide and secondary K plastic; the carbon black is carbon black ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thermal deformation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com