Processing method of label

A processing method and labeling technology, which is applied in the field of marking products, can solve the problems of destroying the integrity and aesthetics of labels, incapable of batch processing and production, and low production efficiency, so as to improve diversity and recognition, and ensure integrity and aesthetics , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

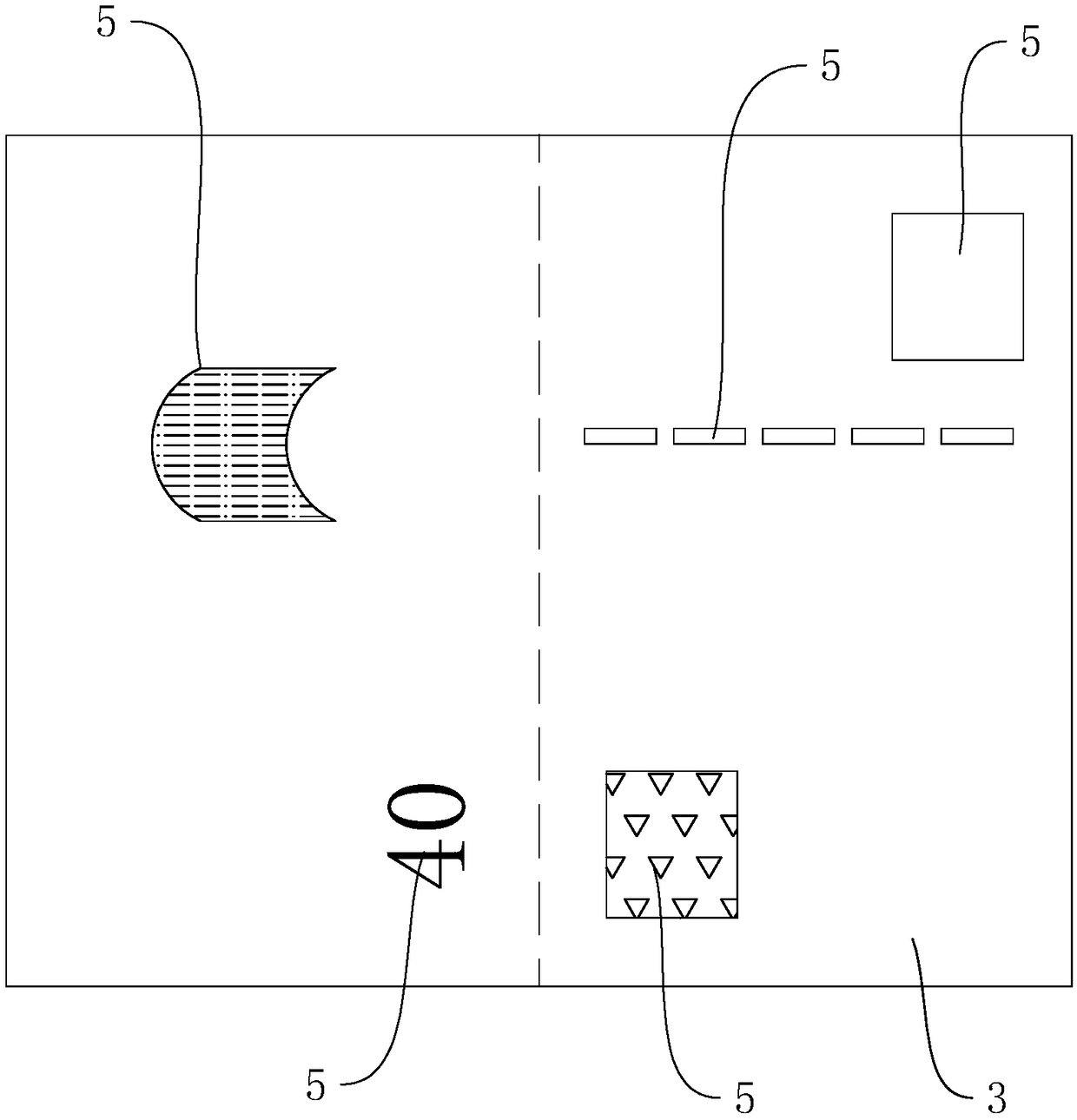

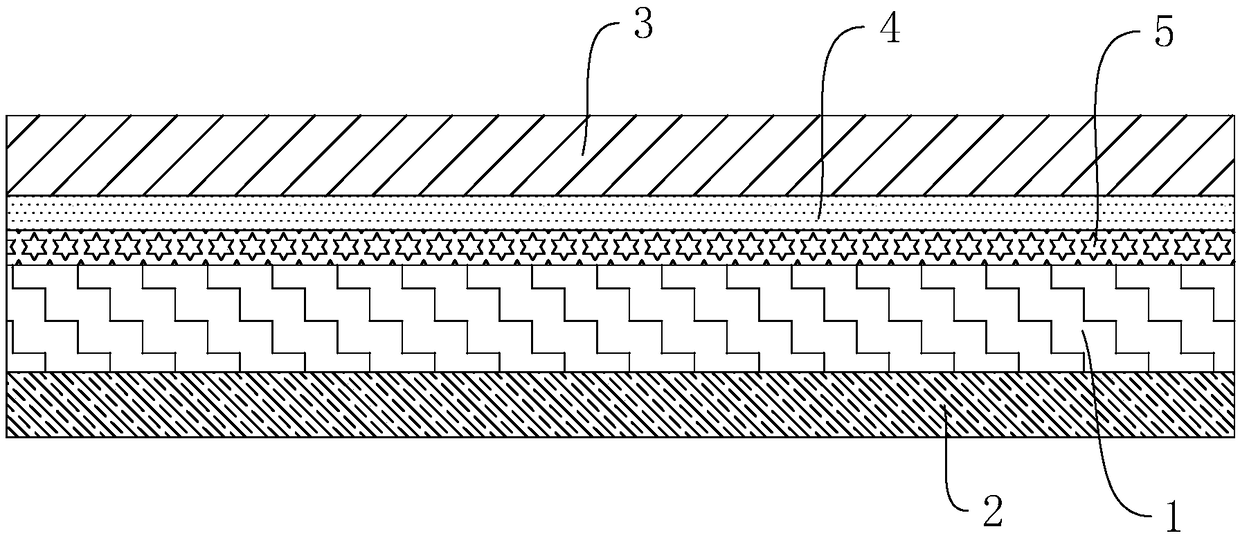

[0038] Example 1: A label, such as figure 1 with figure 2 As shown, it includes a plastic sealing film layer 1 and a soft substrate layer 2 thermoplastically adhered to the plastic sealing film layer 1 . The existence of the above-mentioned plastic sealing film layer 1 is mainly to protect the soft rubber layer, and its interior generally contains polymer plastic components, which have a certain waterproof and shaping effect.

[0039] Secondly, the soft base material layer 2 can use a soft TPE layer, which is a kind of thermoplastic elastomer material and has the advantages of high strength and high resilience. Wherein, the plastic sealing film layer 1 is adhered with a layer of optical film layer 3 on the side away from the soft substrate layer 2 , and a layer of adhesive layer 4 is arranged between the plastic sealing film layer 1 and the optical film layer 3 . In addition, the above-mentioned adhesive layer is a hydrosol layer, and the hydrosol uses water as the dispersi...

Embodiment 2

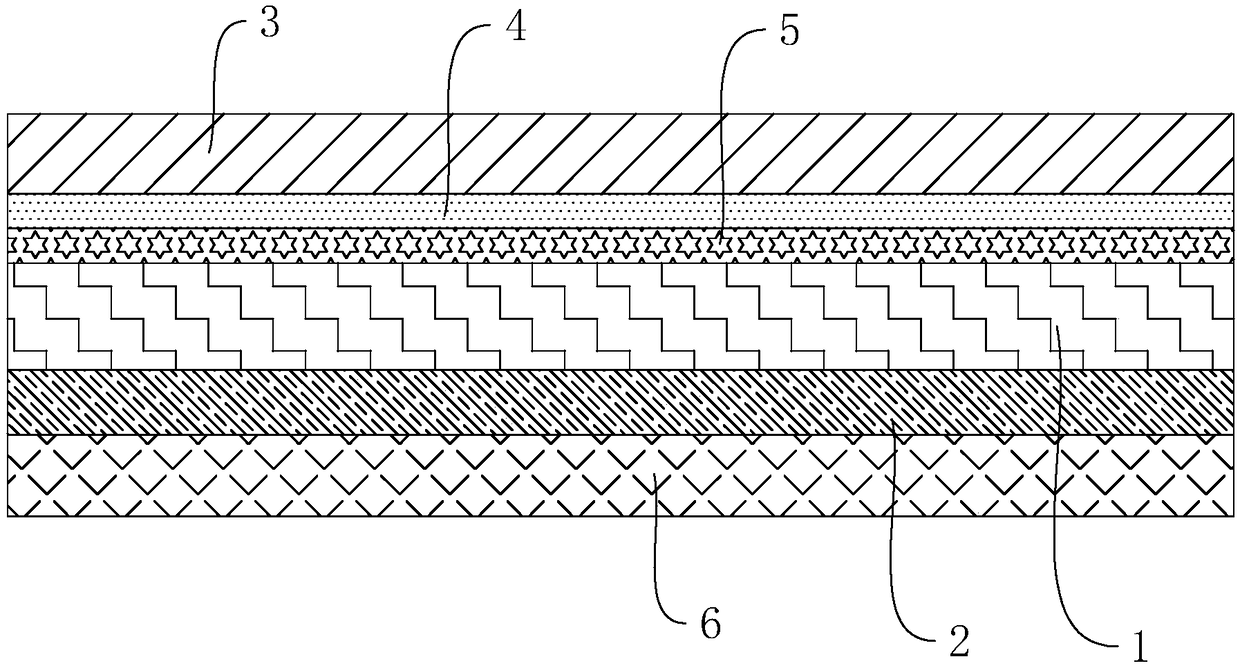

[0047]Embodiment 2: a label, the difference from Embodiment 1 is that the soft substrate layer 2 can be a soft TPR layer. Wherein, the main component of the soft TPR layer is thermoplastic rubber. It has the advantages of high elasticity, high strength and high resilience of rubber, and it also has the characteristics of covering and bonding with PP plastic raw materials, PE plastic raw materials, PC engineering plastics, PS plastics, ABS plastic raw materials and other base materials. .

Embodiment 3

[0048] Embodiment 3: A label, the difference from Embodiment 1 is that the soft substrate layer 2 can be a mixture of a soft TPE layer and a soft TPR layer, wherein between the soft TPE layer and the soft TPR layer The ratio is 1:2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com