A computer vision-based automatic monitoring method for grain storage quantity change in granary

A computer vision and quantity change technology, applied in computer parts, computing, data processing applications, etc., can solve the problems of high energy consumption and time cost, and achieve the effect of fast detection speed and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

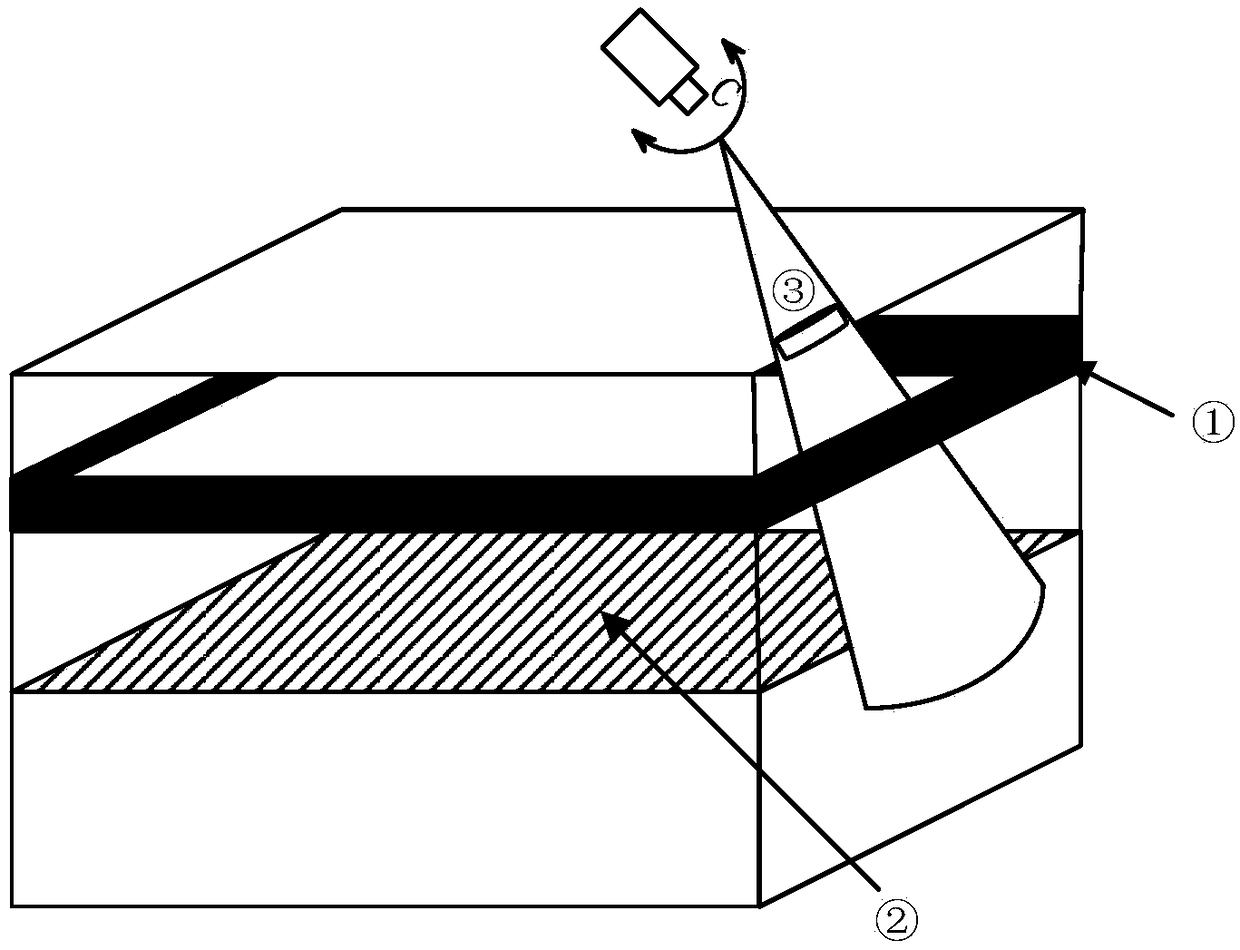

[0026] figure 1 It is a schematic diagram of the monitoring framework of the embodiment of the present invention, as shown in the figure: it includes a camera C, a grain loading line ①, a grain surface ② and a grain outlet ③; the grain loading line ① is distributed around the granary. Among them, the camera C is used to obtain the image of the grain loading line ① and the grain surface ② at the grain outlet ③ of the granary.

[0027] In other embodiments, the grain loading line can be replaced with a marking line, for example: it can be replaced with a marking line set 20-50 cm above the grain loading line; it can also be replaced with a marking set at other corresponding positions according to monitoring needs Wire. If the marking line is used, all the grain loading lines in the subsequent description can be replaced with the marking line, and the methods and steps involved are the same. Among them, both the grain loading line and the marking line are reference lines, which...

Embodiment 2

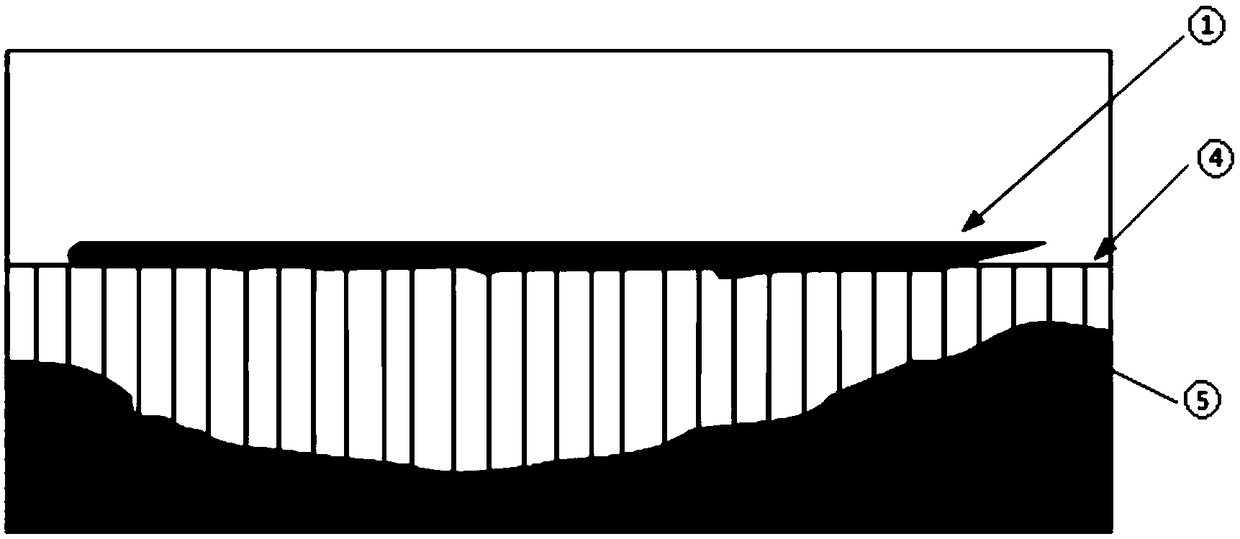

[0065] In this embodiment, the only difference from Embodiment 1 is that when calculating the overall height of the grain surface, the area between the grain loading line and the grain surface is used. The calculation steps are as follows: first, calculate the boundary of each pixel on the grain surface The vertical distance between the point and the straight line of the lower boundary of the fitted grain loading line; then, use the integral method to calculate the area between the grain loading line and the grain surface to obtain the overall height of the grain surface.

[0066] After obtaining the overall height of the grain noodles, compare the overall height of the current grain noodles with the overall height of the grain noodles recorded in history. If the difference between the two is greater than the set threshold, an alarm will be sent to the management personnel; otherwise, the current data will be recorded . For example: Suppose the area from the current grain load...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com