Building blasting vibration damage evaluation method based on high-speed photogrammetry

A blasting vibration and high-speed photography technology, applied in blasting, measuring devices, optical instrument testing, etc., can solve problems such as vibration characteristics and pressure concentration that are not considered, and achieve the effect of avoiding subjectivity, accurate evaluation, and broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

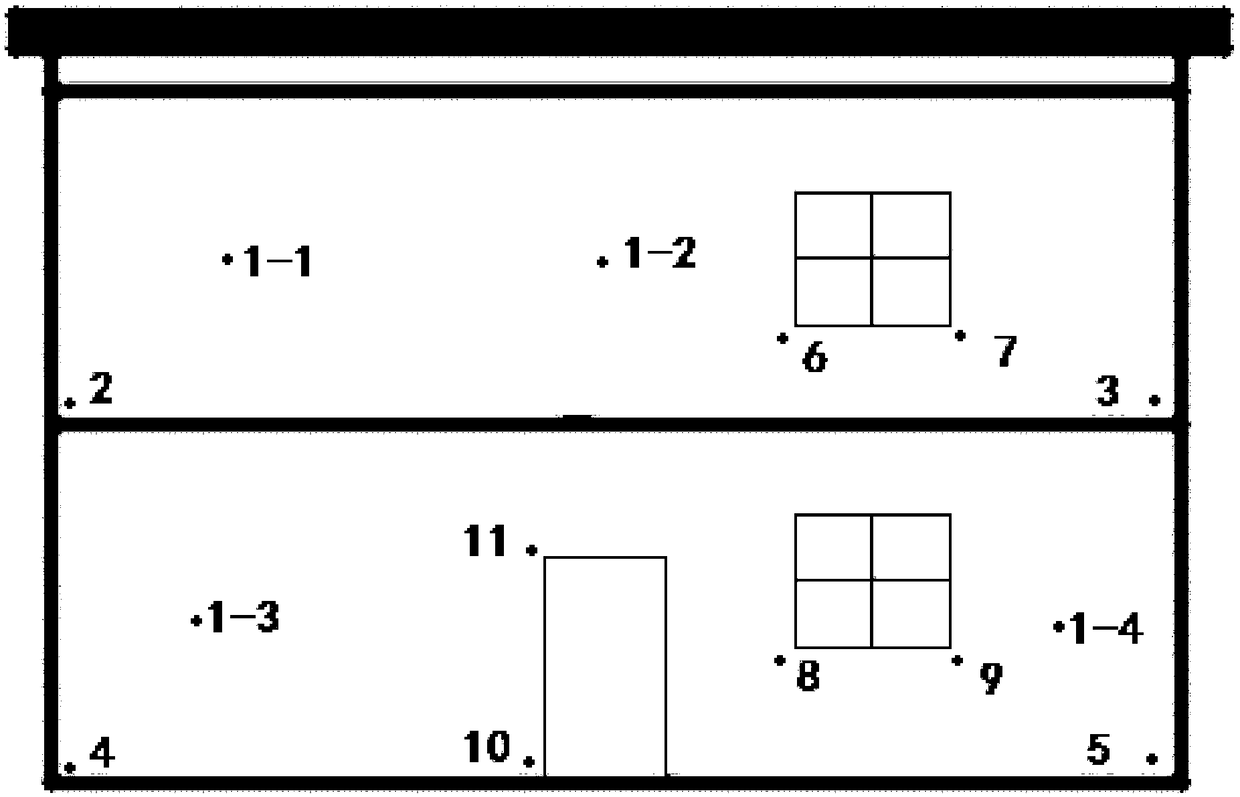

[0020] In this embodiment one, if figure 1 As shown, a two-story building is taken as an example to evaluate blasting vibration damage, which includes the following steps:

[0021] Step 1. First arrange a number of high-speed cameras at suitable positions around the building to take pictures of the whole building, and arrange vibration sensors on the floor and beams of the building, and then connect each instrument through a synchronizer, and carry out data synchronization at the same time. collection.

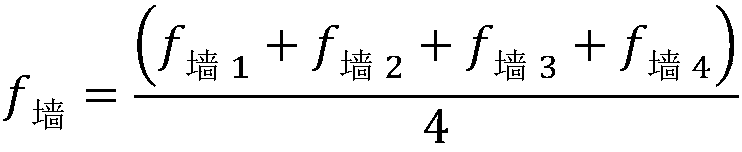

[0022] Step 2. Obtain the vibration curves of various parts of the building based on the collected data, obtain the distribution of the local vibration amplification index for special parts of the structure, determine the weak parts of the structure accordingly, and select a mark point on it, and for the overall A number of marker points are also selected for structural parts; high-speed cameras are used to focus on tracking and shooting of all marker points to obtain vibrati...

Embodiment 2

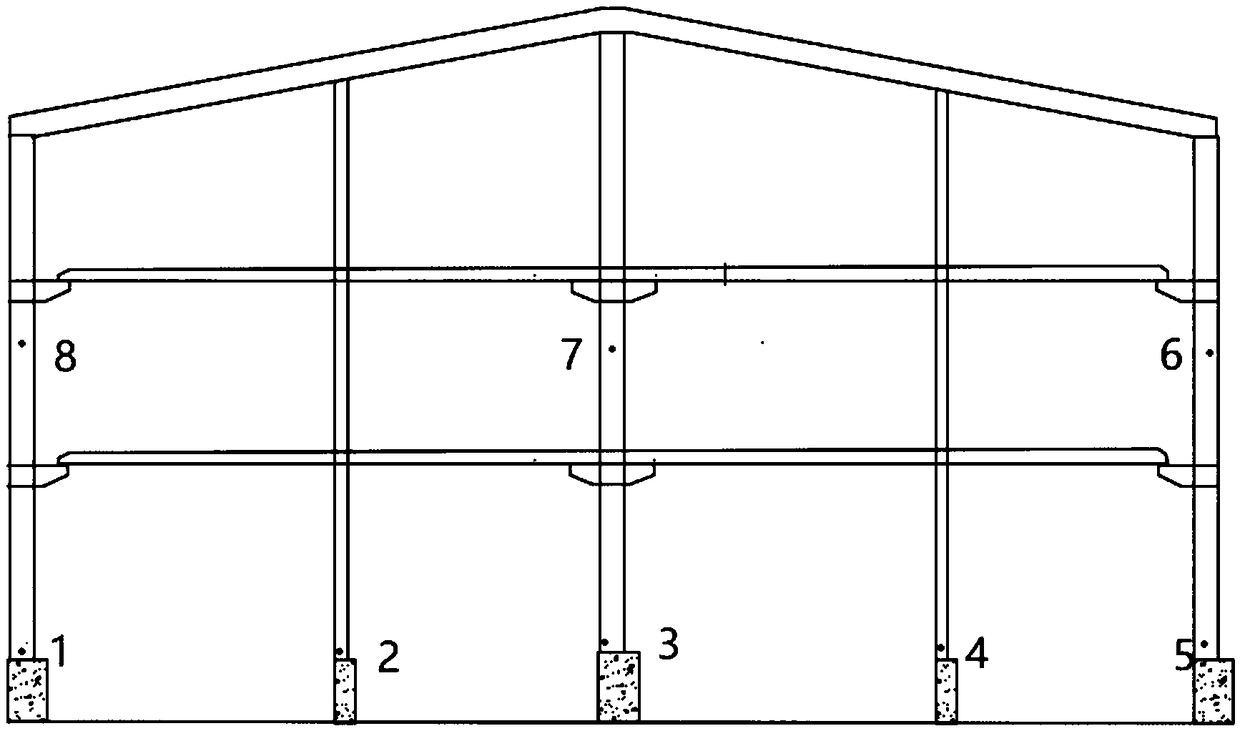

[0035] In the second example, if figure 2 The three-storey steel truss factory building on a construction site is shown as an example for blasting vibration damage assessment, which includes the following steps:

[0036] Step 1. First, arrange a number of high-speed cameras at suitable locations around the factory building to capture the entire factory building. Assuming that the four sides of the factory building are the same, only select the front of the factory building for data collection, and arrange vibration on the floor and beams of the building. Sensors, and then connect the instruments through the synchronizer, and collect data at the same time.

[0037] Step 2. Obtain the vibration curves of various parts of the plant based on the collected data, and obtain the distribution of the local vibration amplification index of the building for a special part of the structure. As for the truss factory building, even when there are serious cracks in the wall, the service li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com