Multifunctional biomechanics energy harvesting textile and preparation method and application thereof

A biomechanical and energy harvesting technology, used in textiles and papermaking, textiles, fabrics, etc., can solve problems such as the lack of triboelectric equipment, and achieve the effects of excellent hydrophobic properties, excellent tensile properties, and simple production processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

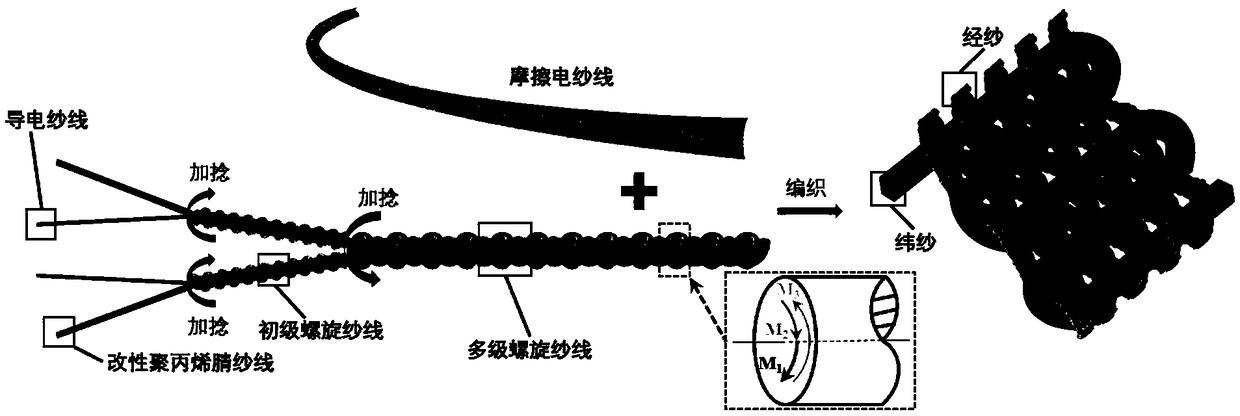

[0040] (1) The polyacrylonitrile yarn grafted with fluorosilane and the conductive yarn are plied and twisted to obtain a primary spiral yarn of 800 twists / m, and then two primary spiral yarns are plied and twisted to obtain a 600 twist / m multi-stage spiral yarn, the directions of the two twists are opposite.

[0041] (2) Insert the conductive yarn into the rubber tube, stretch the rubber tube, use the friction between the rubber tube and the conductive yarn and the compression force at both ends of the rubber tube to make the conductive yarn present a serpentine structure in the rubber tube, and then Two-component epoxy glue was used to seal both ends of the rubber tube to obtain triboelectric yarns.

[0042] (3) Using the multi-stage helical yarn in step (1) as the warp yarn and the triboelectric yarn in step (2) as the weft yarn, plain weave is performed using a knitting machine. First, adjust the position of the heald frame, and set the parameters on the writing board sc...

Embodiment 2

[0050]In embodiment 1 step (1), "obtain the primary spiral yarn of 800 twist / m" to "obtain the primary spiral yarn of 600 twist / m", change "obtain the multistage spiral yarn of 600 twist / m" In order to "obtain a multi-stage spiral yarn of 450 twist / m", change the "working air pressure to 0.6MPa, and the picking amount per minute to 70 times" in step (2) to "the working air pressure is set to 0.5MPa, every The amount of picking per minute is set to 60 times", and the rest are the same as in Example 1 to obtain energy harvesting textiles.

[0051] Figure 10 It shows that the twist of the multi-stage helical yarn is reduced, and the output performance of the energy harvesting textile is reduced.

Embodiment 3

[0053] In embodiment 1 step (1), "obtain the primary helical yarn of 800 twist / m" to "obtain the primary helical yarn of 400 twist / m", "obtain the multistage helical yarn of 600 twist / m" into "Obtain a multi-stage spiral yarn with 300 twist / m", change the "working air pressure is set to 0.6MPa, and the picking amount per minute is set to 70 times" in step (2) to "the working air pressure is set to 0.4MPa, every minute The amount of picking was set to 50 times, and the rest were the same as in Example 1 to obtain energy-harvesting textiles.

[0054] Figure 11 It is shown that as the twist of the multi-stage helical yarn decreases, the yarn bonding becomes loose and the output performance of the energy harvesting textile decreases.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com