Continuous glass fiber reinforced polypropylene unidirectional prepreg tape and its preparation method

A unidirectional prepreg tape and glass fiber technology, applied in the field of continuous fiber reinforced thermoplastic composite materials, can solve the problems of limited selection range, complicated process, high cost, etc., and achieve the effect of improving impregnation speed and wetting ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A continuous glass fiber reinforced polypropylene unidirectional prepreg tape is prepared as follows:

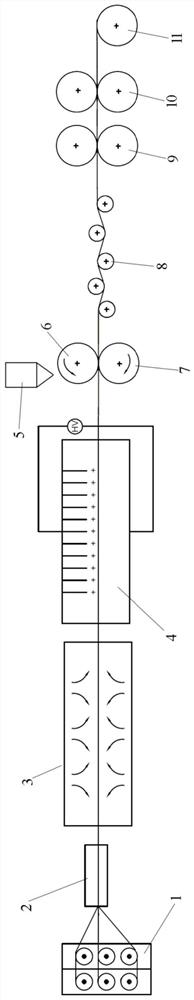

[0024] (1) 20 parts by weight of polypropylene with a melt index of 80g / 10min, 5 parts by weight of polypropylene grafted zinc maleic anhydride and 0.03 parts by weight of antioxidant 1010 are mixed evenly at high speed, and added figure 1 Mix and plasticize uniformly in the twin-screw extruder 5 with medium length-to-diameter ratio of 44, extrusion temperature of 170°C, and host speed of 500r / min, and extrude the obtained polypropylene-based melt mixture to a coating roller with a constant temperature of 170°C 6 surfaces;

[0025] (2) 80 parts by weight of continuous glass fibers are pulled by the creel 1 at a speed of 6m / min, after the continuous glass fibers are flattened to a planar shape by the spreading device 2, continue to draw the planar continuous glass fibers through a constant temperature to The oven 3 at 180°C is preheated to 180°C, and then the planar ...

Embodiment 2

[0028] A continuous glass fiber reinforced polypropylene unidirectional prepreg tape is prepared as follows:

[0029] (1) Mix 30 parts of polypropylene with a melt index of 20g / 10min, 1 part of polypropylene grafted zinc maleic anhydride and 0.07 part of antioxidant 1010 at high speed, and add figure 1 Mix and plasticize uniformly in the twin-screw extruder 5 with medium length-to-diameter ratio of 44, extrusion temperature of 190°C, and host speed of 800r / min, and extrude the obtained polypropylene-based melt mixture to a coating roller with a constant temperature of 190°C 6 surfaces;

[0030] (2) 70 parts of continuous glass fibers are pulled by the creel 1 at a speed of 8m / min, after the continuous glass fibers are flattened to a flat shape by the spreading device 2, continue to pull the flat continuous glass fibers through the constant temperature to 200 The oven 3 at ℃ is preheated to 200 ℃, and then the planar continuous glass fiber is pulled through the corona chargin...

Embodiment 3

[0033] A continuous glass fiber reinforced polypropylene unidirectional prepreg tape is prepared as follows:

[0034] (1) Mix 25 parts of polypropylene with a melt index of 50g / 10min, 3 parts of polypropylene grafted zinc maleic anhydride and 0.05 part of antioxidant 1010 at high speed, and add figure 1 Mix and plasticize uniformly in the twin-screw extruder 5 with medium length-to-diameter ratio of 44, extrusion temperature of 180°C, and host speed of 650r / min, and extrude the obtained polypropylene-based melt mixture to a coating roller with a constant temperature of 185°C 6 surfaces;

[0035] (2) 60 parts of continuous glass fibers are pulled by the creel 1 at a speed of 4m / min, after the continuous glass fibers are flattened to a flat shape by the spreading device 2, continue to pull the flat continuous glass fibers through the constant temperature to 190 The oven 3 at ℃ is preheated to 190 ℃, and then the planar continuous glass fiber is pulled through the corona chargi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com