Flame-retardant copolyester material for automobile interior trim, and preparation method of flame-retardant copolyester material

A technology of automotive interior and copolyester, which is applied in the field of flame retardant copolyester materials and preparation, can solve the problems of casualty economy, melt dripping, environmental pollution, etc., and achieve improved rigidity, glass transition temperature, oxygen The effect of high index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Heat and melt dimethyl terephthalate, then add ethylene glycol, stir evenly, add stannous octoate and titanium chloride, heat up to 228°C, react for 34 minutes, then vacuumize and continue the reaction for 48 minutes to obtain Ethylene terephthalate prepolymer; the molar ratio of dimethyl terephthalate, ethylene glycol, stannous octoate, and titanium chloride is 100:100:0.7:1.6;

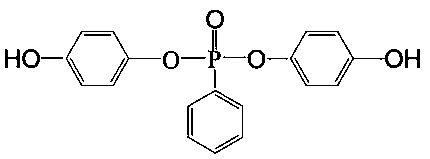

[0026] (2) Add hydroquinone into toluene solvent, then add phenylphosphonyl dichloride dropwise, heat to 88°C for 17h under the protection of nitrogen, then cool down to 67°C for 4h, then filter, wash, and vacuum-dry to prepare Bis(4-hydroxyphenyl)phenylphosphine oxide is obtained; the molar ratio of hydroquinone and phenylphosphonic dichloride is 2.26:1;

[0027] (3) Add bis(4-methylphenyl)phenylphosphine oxide to sodium hydroxide solution, adjust the pH value to 11.5, add potassium permanganate, heat to 93°C for 10.5h oxidation, then cool down to room temperature, and add hydrochloric ac...

Embodiment 2

[0030] (1) Heat and melt dimethyl terephthalate, then add ethylene glycol, stir evenly, add stannous octoate and titanium chloride, heat up to 224°C, react for 38 minutes, then vacuumize and continue the reaction for 45 minutes to obtain Ethylene terephthalate prepolymer; the molar ratio of dimethyl terephthalate, ethylene glycol, stannous octoate, and titanium chloride is 100:100:0.6:1.2;

[0031] (2) Add hydroquinone into toluene solvent, then add phenylphosphonyl dichloride dropwise, heat to 85°C for 19h under nitrogen protection, then cool down to 66°C for 4.5h, then filter, wash, and vacuum dry. Bis(4-hydroxyphenyl)phenylphosphine oxide was prepared; the molar ratio of hydroquinone and phenylphosphonic dichloride was 2.22:1;

[0032] (3) Add bis(4-methylphenyl)phenylphosphine oxide to sodium hydroxide solution, adjust the pH value to 11, add potassium permanganate, heat to 91°C for 11.5h, then cool down to room temperature, and add hydrochloric acid Until the solution is...

Embodiment 3

[0035] (1) Heat and melt dimethyl terephthalate, then add ethylene glycol, stir evenly, add stannous octoate and titanium chloride, heat up to 235°C, react for 33 minutes, then vacuumize and continue the reaction for 55 minutes to obtain Ethylene terephthalate prepolymer; the molar ratio of dimethyl terephthalate, ethylene glycol, stannous octoate, and titanium chloride is 100:100:0.9:1.8;

[0036](2) Add hydroquinone into toluene solvent, then add phenylphosphonyl dichloride dropwise, heat to 95°C for 16h under nitrogen protection, then cool down to 68°C for 3.5h, then filter, wash, and vacuum dry. Bis(4-hydroxyphenyl)phenylphosphine oxide was prepared; the molar ratio of hydroquinone and phenylphosphonyl dichloride was 2.28:1;

[0037] (3) Add bis(4-methylphenyl)phenylphosphine oxide to sodium hydroxide solution, adjust the pH value to 12, add potassium permanganate, heat to 95°C for 10.5h, then cool down to room temperature, and add hydrochloric acid Until the solution is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com