Method for producing high-purity etamsylate

A high-purity technology of ethylamine, which is applied in the field of preparation of ethylamine, can solve the problems of unfriendly environment and high toxicity of ethylamine, and achieve the goals of shortening post-processing time, simplifying operation and reducing energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

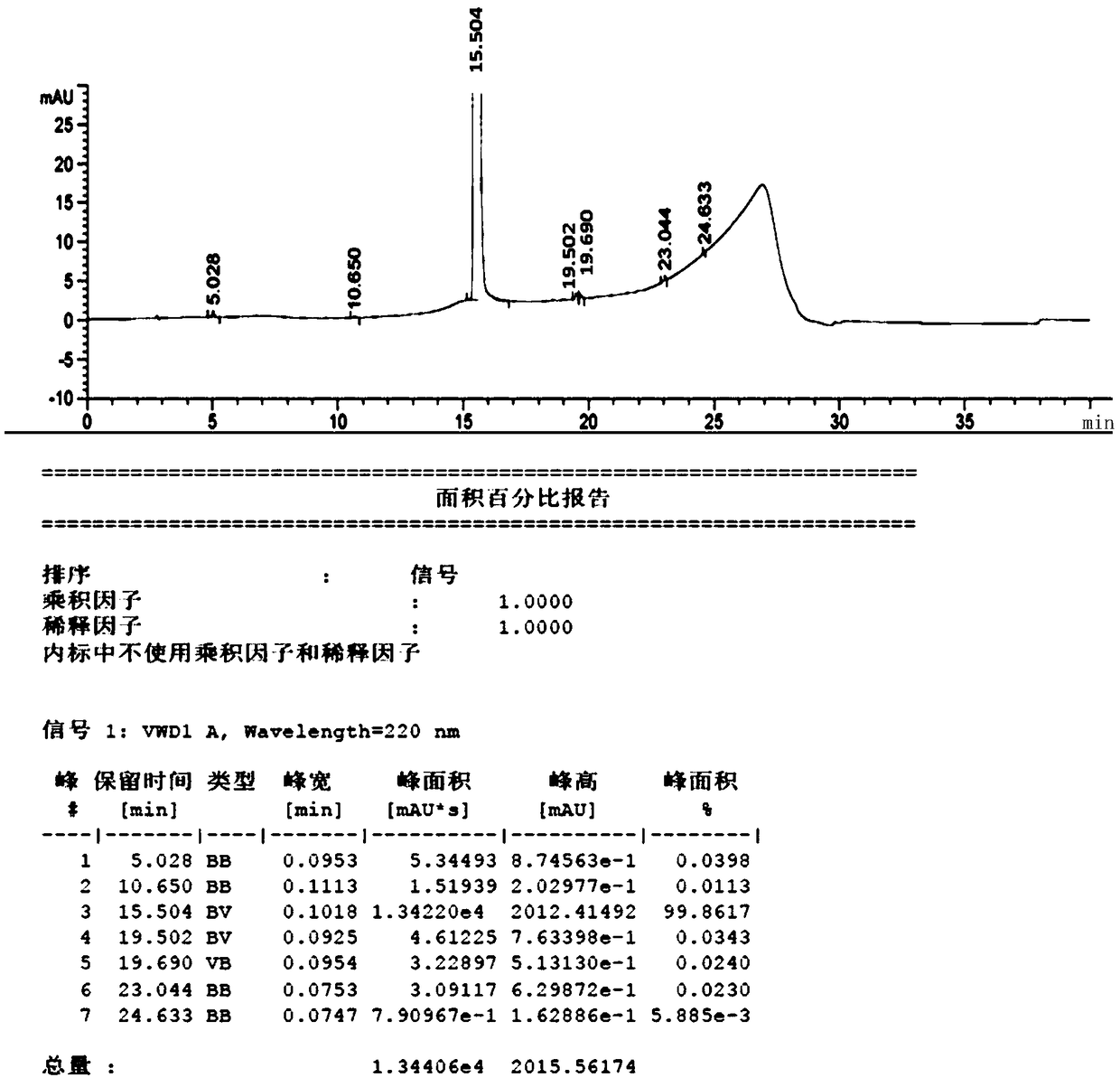

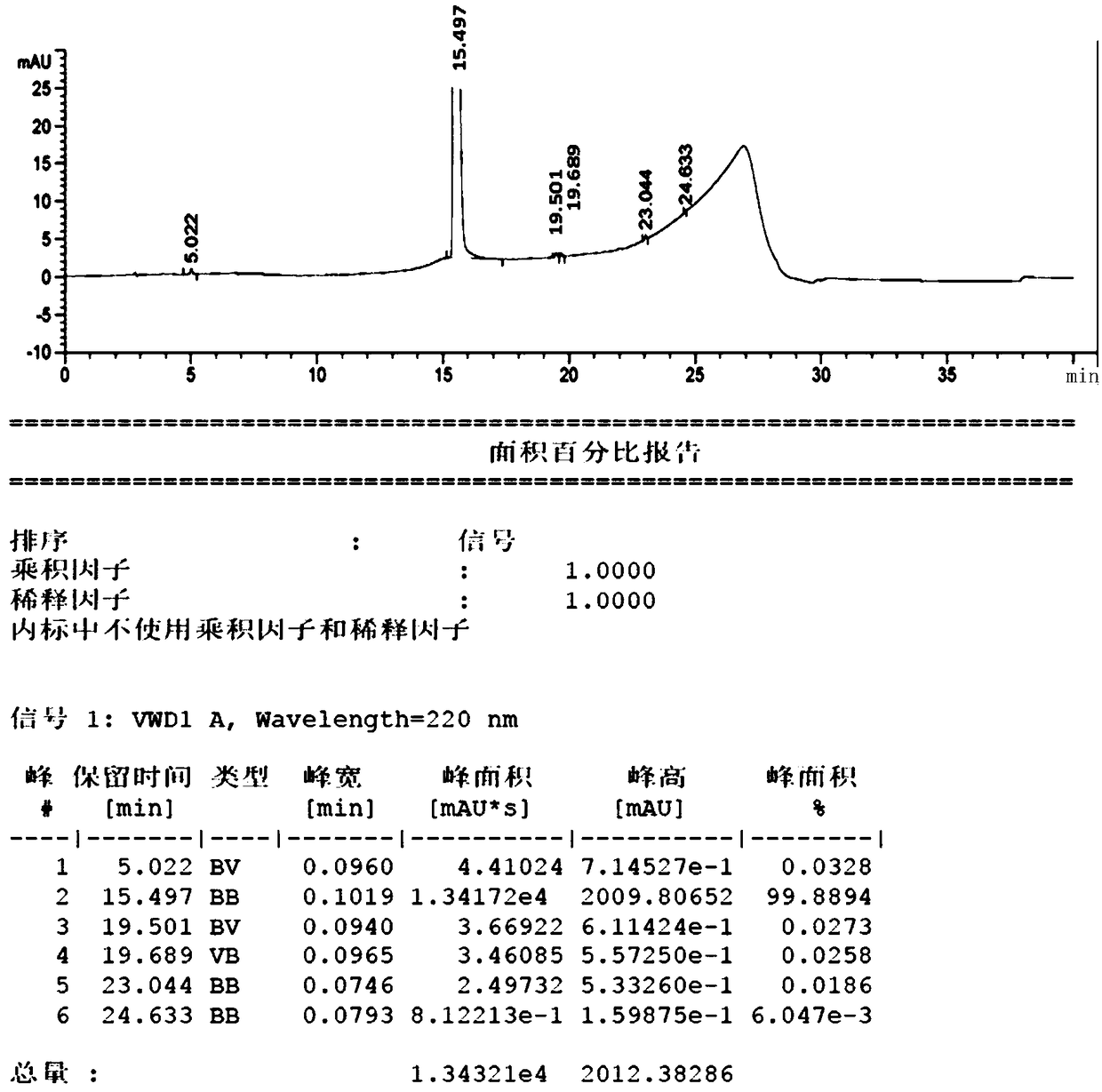

Image

Examples

Embodiment 1

[0030] Add 1.65kg of hydroquinone, 4.5L of n-heptane, and 0.22L of glacial acetic acid into a 10L enamel reaction kettle, stir and heat up to reflux, reflux and divide water for 2 hours, after water separation, cool down to slight reflux, that is, control the temperature in the enamel reaction kettle. temperature to 80°C, add 2.28kg of concentrated sulfuric acid, and control the internal temperature to not exceed 90°C. After the addition is complete, keep warm at 85°C, and react with slight reflux for 30 minutes. Stop heating, pass in cooling water to lower the temperature of the paste in the lower layer to 45°C, and drop in 1.42 The mixed solution of kg diethylamine and 0.99L water is added dropwise at an internal temperature of 55°C. After the drop is completed, the temperature is raised to 65°C and stirred to dissolve the lower aqueous phase. Cool down to 10°C, keep stirring and crystallize for 1h. Then lower the temperature to 0°C, heat preservation, stir and crystallize f...

Embodiment 2

[0032] Add 1.65kg of hydroquinone, 4.2L of n-hexane, and 0.2L of acetic anhydride into a 10L enamel reaction kettle, stir and heat up to reflux, reflux and divide water for 1 hour, after water separation, cool down to microreflux, and control the internal temperature of the microreflux reactor 70°C, add 1.9kg of concentrated sulfuric acid, control the internal temperature of the reactor to not exceed 75°C, after the addition is complete, keep warm for 50 minutes under reflux, stop heating, pass in cooling water to lower the temperature of the paste in the lower layer to 50°C, and drop 1.4kg of di For the mixture of ethylamine and 0.9L water, add dropwise at an internal temperature of 50°C, and the maximum temperature should not exceed 70°C. After dropping, raise the temperature to 70°C and stir to dissolve the lower aqueous phase. Reactor, slowly cool down to about 10°C, keep stirring and crystallize for 1 hour, then cool down to 3°C, keep stirring and crystallize, then dischar...

Embodiment 3

[0034] Add 1.65kg of hydroquinone, 4.5L of cyclohexane, and 0.2L of propionic acid into a 10L enamel reaction kettle, stir and raise the temperature to reflux, and reflux to separate water for 2 hours. After the water separation is completed, the temperature is lowered to a slight reflux. The inner temperature of the micro-reflux reactor is 85°C, and 2.28kg of concentrated sulfuric acid is added to control the inner temperature of the reactor to not exceed 90°C; Put in cooling water to lower the temperature of the paste in the lower layer to 65°C, add a mixture of 1.25kg of diethylamine and 0.9L of water dropwise, control the inner temperature of the reactor at 65°C, and the maximum temperature of the reactor should not exceed 70°C; Stir to 70°C to dissolve the lower water phase, and separate the liquid while it is hot; collect the water phase, transfer it to a 10L reactor, slowly cool down to about 10°C, keep stirring and crystallize for 1 hour, then cool down to 5°C, keep sti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com