Wear-resisting and scraping-resisting chameleon color-coated board and preparation method thereof

A chameleon and color-coated board technology, applied in the field of materials, can solve problems such as abrupt and jumping changes, and achieve the effects of enhancing adhesion, improving scratch resistance and wear resistance, and improving mechanical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

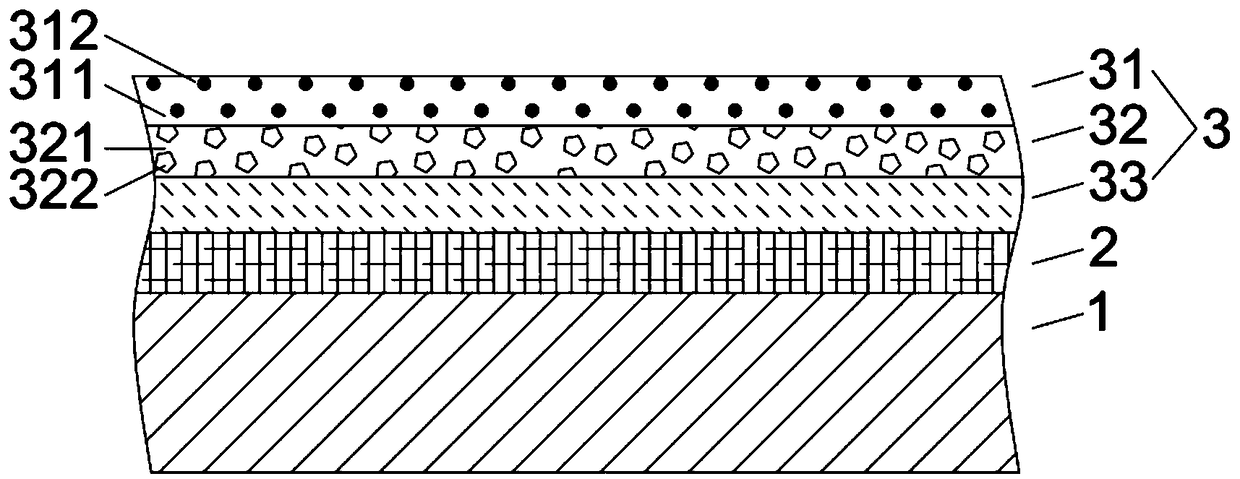

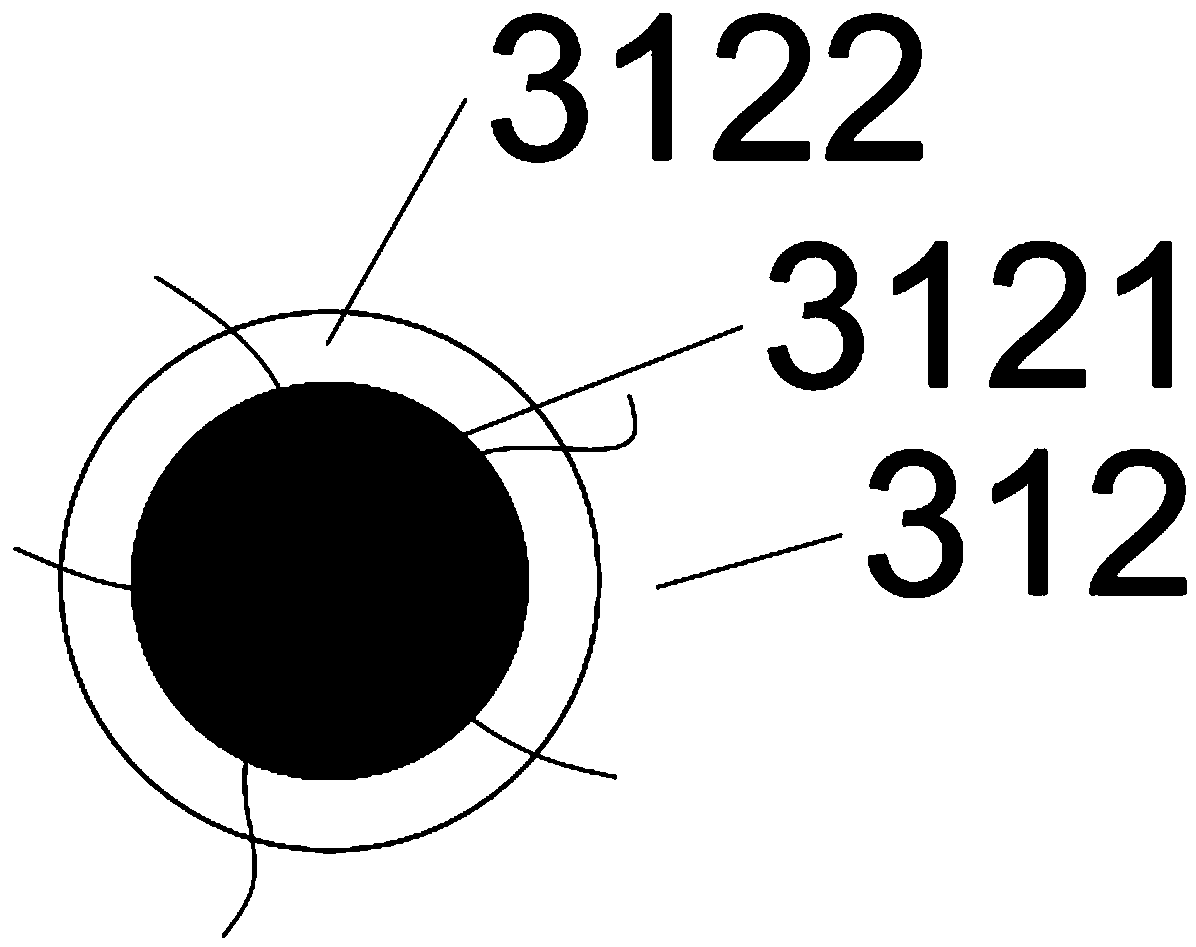

[0049] The invention provides a wear-resistant and scratch-resistant chameleon color-coated board, such as figure 1 As shown, it includes a base material 1 , an adhesive layer 2 and a chameleon paint film 3 which are sequentially stacked.

[0050] The base material 1 is a steel plate. Preferably, the base material 1 is a cold-rolled base material with a thickness of 0.3 mm.

[0051] Such as figure 1 As shown, the adhesive layer 2 is coated on the substrate 1 . Preferably, the adhesive layer is a mixture of epoxy resin, ethylene-octyl acrylate copolymer, polyvinyl alcohol and aluminum oxide particles, with a mass ratio of 10:5:5:2. Epoxy resin and ethylene-octyl acrylate copolymer have good cohesive force, so that the chameleon paint film 3 and the substrate 1 are firmly bonded, and the mechanical properties of the wear-resistant and scratch-resistant chameleon color-coated board are enhanced; at the same time, the polyethylene Under the action of alcohol, the alumina partic...

Embodiment 2

[0062] The present invention provides a wear-resistant and scratch-resistant chameleon color-coated board. The difference from Embodiment 1 is that the reflective layer 33 is not provided separately, but a material with reflective function is selected as the adhesive layer 2 to realize the protection against the pigment light. Reflection, reduce light loss and increase light output rate.

[0063] As an alternative embodiment, the reflective layer 33 may not be provided, but the intensity of light may be enhanced by increasing the proportion of the pigment 322 in the second base material 311 .

Embodiment 3

[0065] The present invention provides a wear-resistant and scratch-resistant chameleon color-coated board. The difference from Embodiment 1 is that the material of the second base material 321 can also be poly-n-butyl methacrylate, or polymethyl methacrylate and polymethyl methacrylate. A mixture of n-butyl acrylate; the thickness of the second film layer 32 can also be other values in the range of 10-14 μm except 12 μm, such as 10 μm, 11 μm, 14 μm, etc., as long as the second film layer 32 and the first film layer can be realized. The reflected light at the 31 interface interferes with the initial light multiple times to eliminate stray light, so as to improve the color purity of the light and ensure that the light intensity does not attenuate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com