A cable core recycling separator

A separator and cable core technology, applied in the field of separators, can solve the problems of high labor intensity and slow separation speed, and achieve the effects of reducing labor burden, fast separation speed, and reducing labor burden.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

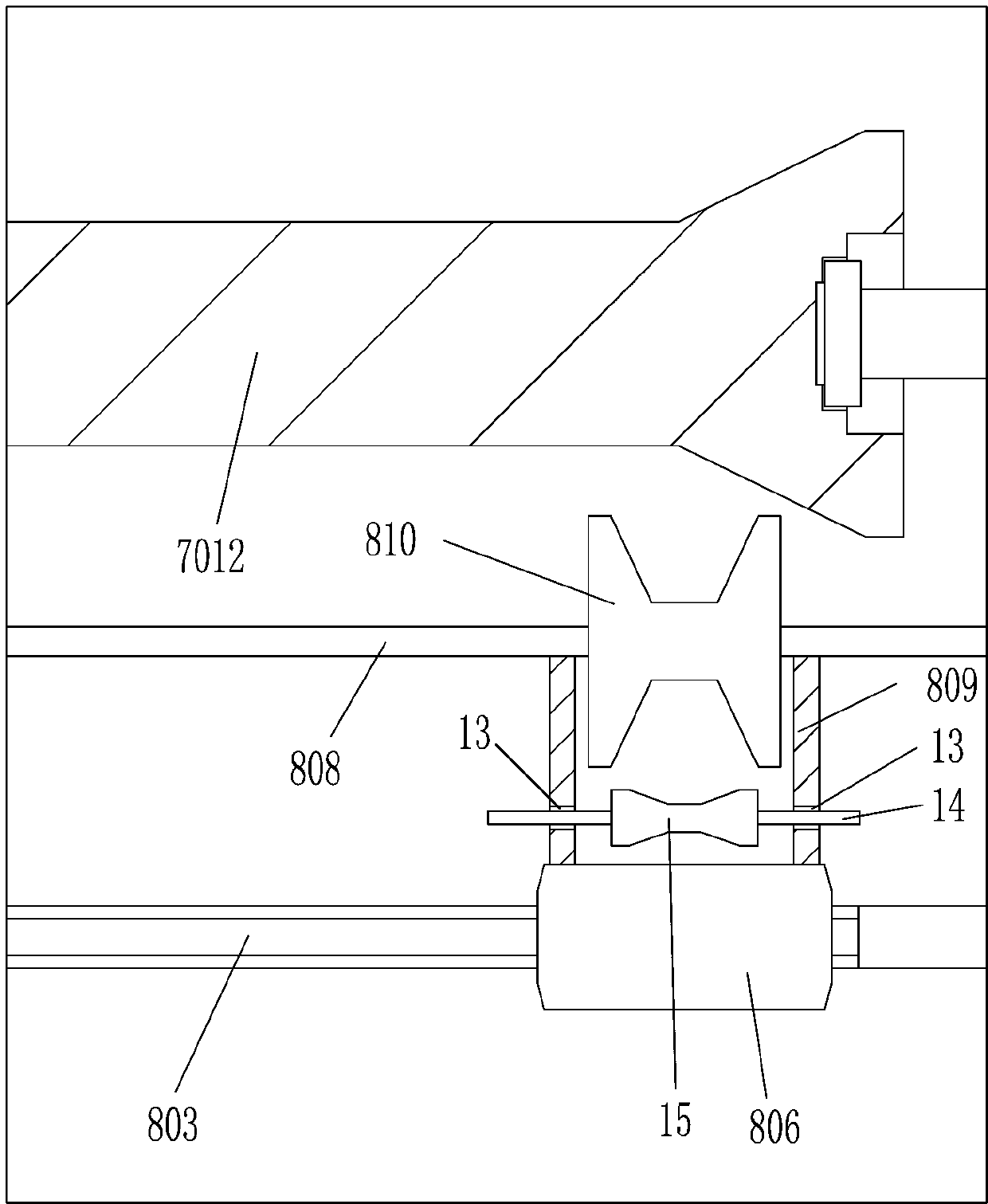

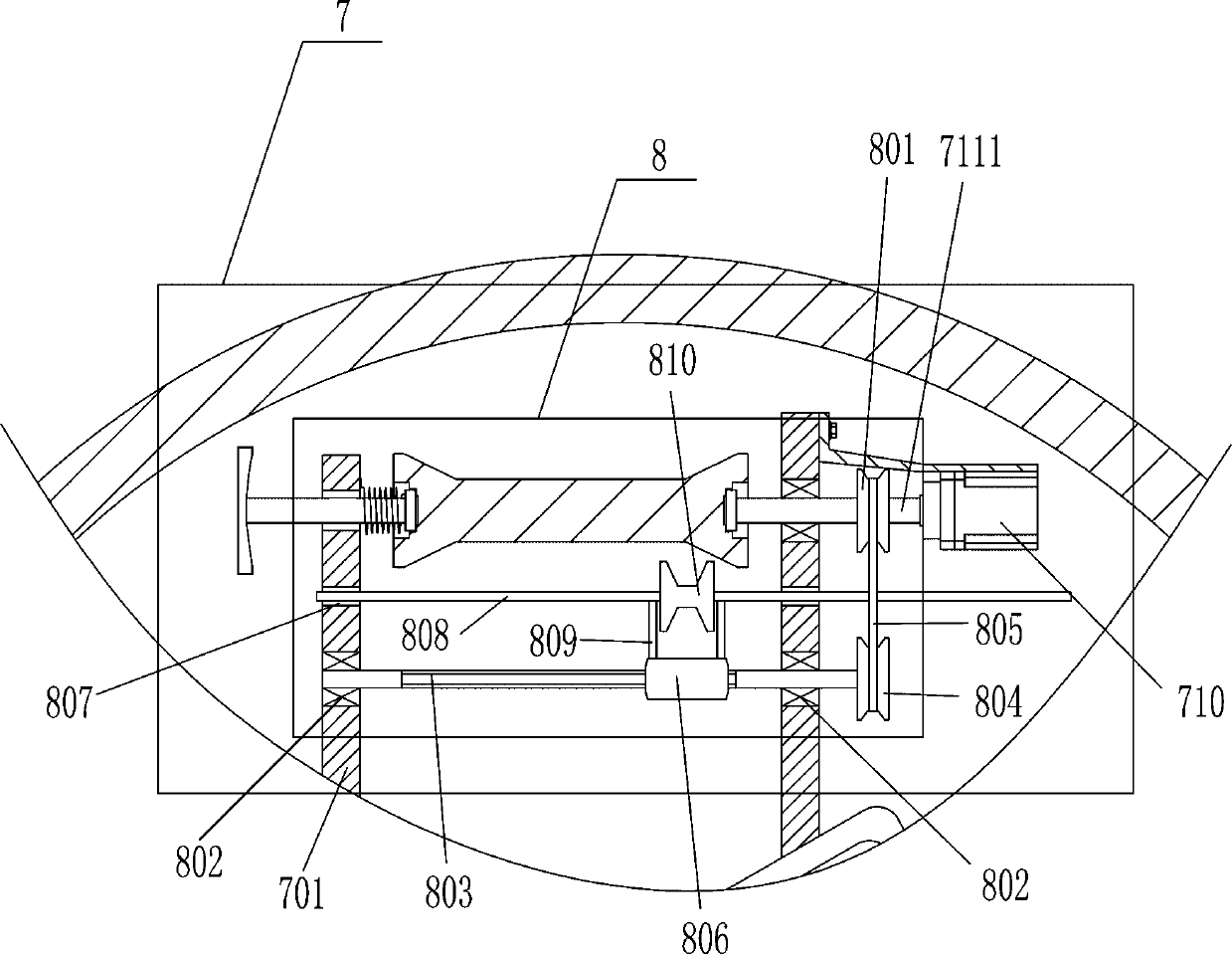

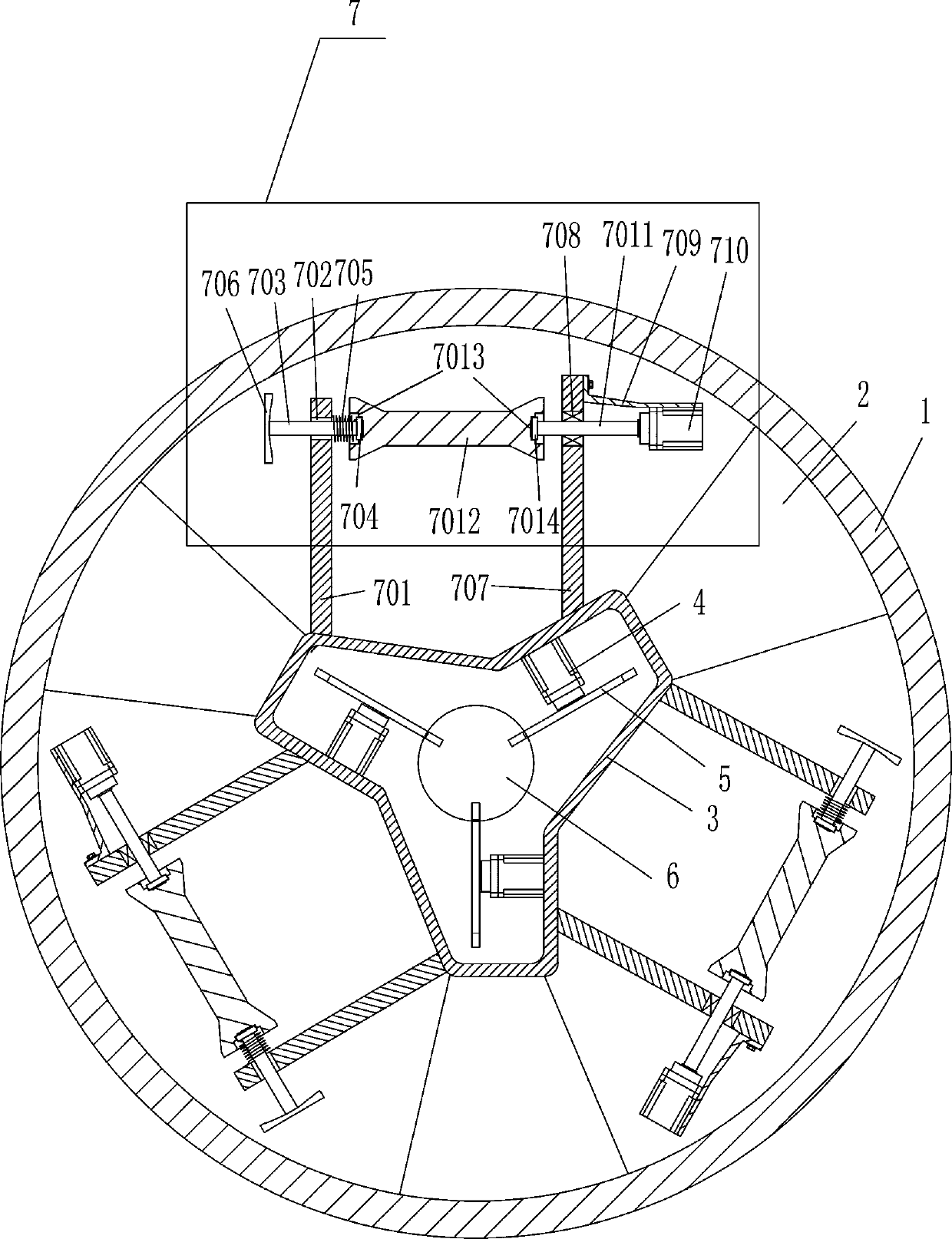

[0020] A cable core recovery separator, such as Figure 1-4 As shown, it includes a support 1, a support plate 2, a groove box 3, a first motor 4, a cutting knife 5 and a dismantling coiling device 7, and the inner wall of the support 1 is connected with three support plates 2 at even intervals, and the three support plates 2. The inner side is connected with the groove box 3, the first through hole 6 is opened in the middle of the top of the groove box 3, and the inner wall of the groove box 3 is installed with three first motors 4 evenly spaced, and the output shaft of the first motor 4 is connected by a coupling There is a cutting knife 5, and the outer wall of the groove box 3 is evenly spaced with three dismantling coiling devices 7. The dismantling coiling device 7 includes a first bracket 701, a first rotating shaft 703, a first coupling disc 704, a spring 705, and a handle 706, the second bracket 707, the first bearing 708, the first pole 709, the second motor 710, the...

Embodiment 2

[0022] A cable core recovery separator, such as Figure 1-4As shown, it includes a support 1, a support plate 2, a groove box 3, a first motor 4, a cutting knife 5 and a dismantling coiling device 7, and the inner wall of the support 1 is connected with three support plates 2 at even intervals, and the three support plates 2. The inner side is connected with the groove box 3, the first through hole 6 is opened in the middle of the top of the groove box 3, and the inner wall of the groove box 3 is installed with three first motors 4 evenly spaced, and the output shaft of the first motor 4 is connected by a coupling There is a cutting knife 5, and the outer wall of the groove box 3 is evenly spaced with three dismantling coiling devices 7. The dismantling coiling device 7 includes a first bracket 701, a first rotating shaft 703, a first coupling disc 704, a spring 705, and a handle 706, the second bracket 707, the first bearing 708, the first pole 709, the second motor 710, the ...

Embodiment 3

[0025] A cable core recovery separator, such as Figure 1-4 As shown, it includes a support 1, a support plate 2, a groove box 3, a first motor 4, a cutting knife 5 and a dismantling coiling device 7, and the inner wall of the support 1 is connected with three support plates 2 at even intervals, and the three support plates 2. The inner side is connected with the groove box 3, the first through hole 6 is opened in the middle of the top of the groove box 3, and the inner wall of the groove box 3 is installed with three first motors 4 evenly spaced, and the output shaft of the first motor 4 is connected by a coupling There is a cutting knife 5, and the outer wall of the groove box 3 is evenly spaced with three dismantling coiling devices 7. The dismantling coiling device 7 includes a first bracket 701, a first rotating shaft 703, a first coupling disc 704, a spring 705, and a handle 706, the second bracket 707, the first bearing 708, the first pole 709, the second motor 710, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com