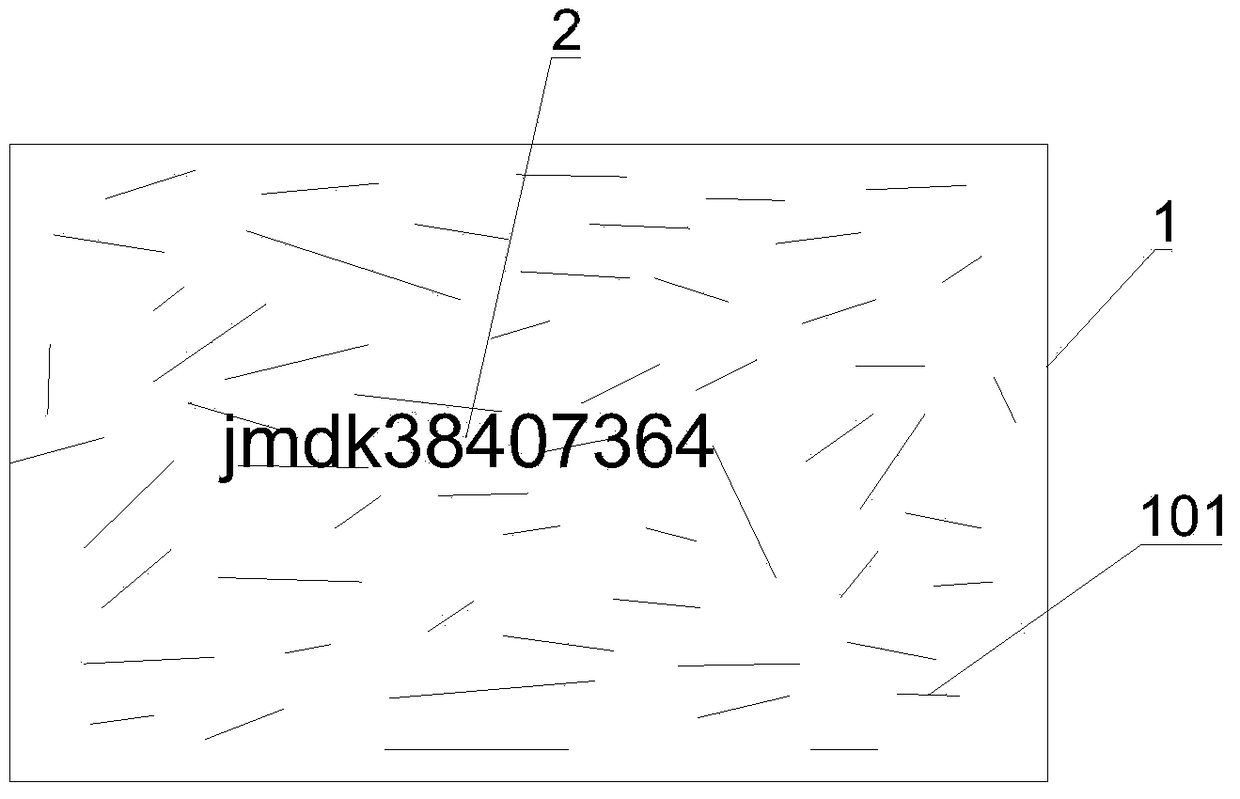

Fragile anti-fake label with fibers arrayed randomly and directionally and preparation method of fragile anti-fake label

An anti-counterfeiting label and random arrangement technology, which is applied in the field of fragile anti-counterfeiting labels and their preparation, can solve the problems of laser anti-counterfeiting labels that are not easily torn, cannot be written, and have no touch, and are easy to popularize and use, have identification, and anti-counterfeiting. Evenly arranged effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A fragile anti-counterfeiting label, which is divided into three layers, which are release paper, self-adhesive layer and anti-counterfeiting coating in sequence, wherein the anti-counterfeiting coating is obtained by coating and drying water-based ink on the surface of the self-adhesive layer.

[0033] Described aqueous ink is prepared from following raw material by weight:

[0034] 66 parts of water-based acrylic resin, 0.5 parts of fatty acid dispersant, 1.5 parts of polysiloxane defoamer, 1.0 parts of silicone leveling agent, 1.0 parts of polyurethane thickener, 20 parts of titanium dioxide, 10 parts of calcium carbonate and 5.26 parts Nylon fibers in red.

[0035] The preparation method of the water-based ink is obtained by uniformly mixing water-based acrylic resin, dispersant, defoamer, leveling agent, thickener, titanium dioxide, calcium carbonate and fibrous materials.

[0036] The steps of the preparation method of the anti-counterfeit label are as follows: t...

Embodiment 2

[0038] A fragile anti-counterfeiting label, which is divided into three layers, which are release paper, self-adhesive layer and anti-counterfeiting coating in sequence, wherein the anti-counterfeiting coating is obtained by coating and drying water-based ink on the surface of the self-adhesive layer.

[0039] Described aqueous ink is prepared from following raw material by weight:

[0040] 66 parts of water-based acrylic resin, 0.5 parts of fatty acid dispersant, 1.5 parts of polysiloxane defoamer, 1.0 parts of silicone leveling agent, 1.0 parts of polyurethane thickener, 20 parts of titanium dioxide, 10 parts of calcium carbonate and 5.26 parts Blue nylon fibers.

[0041] The preparation method of the water-based ink is obtained by uniformly mixing water-based acrylic resin, dispersant, defoamer, leveling agent, thickener, titanium dioxide, calcium carbonate and fibrous materials.

[0042] The steps of the preparation method of the anti-counterfeit label are as follows: the...

Embodiment 3

[0044] A fragile anti-counterfeiting label, which is divided into three layers, which are release paper, self-adhesive layer and anti-counterfeiting coating in sequence, wherein the anti-counterfeiting coating is obtained by coating and drying water-based ink on the surface of the self-adhesive layer.

[0045] Described aqueous ink is prepared from following raw material by weight:

[0046] 50 parts of methylcellulose, 1.0 part of fatty acid dispersant, 0.5 part of polysiloxane defoamer, 0.8 part of silicone leveling agent, 0.5 part of polyurethane thickener, 30 parts of titanium dioxide, 1 part of calcium carbonate and 8 part green polyester.

[0047] The preparation method of the water-based ink is obtained by uniformly mixing methylcellulose, dispersant, defoamer, leveling agent, thickener, titanium dioxide, calcium carbonate and polyester fiber.

[0048] The steps of the preparation method of the anti-counterfeit label are as follows: the self-adhesive is coated on the re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com