Prefabricated sleeve pipe pile capable of eliminating friction force of swelling-shrinking soil layer, and construction method thereof

A technology of prefabricated piles and friction, applied in the direction of sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of limited scope of application, difficult construction, low bearing capacity, etc., and achieve convenient material acquisition, reliable quality, and pile bearing capacity high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

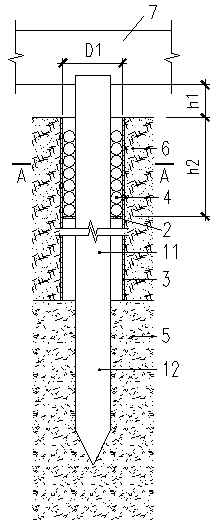

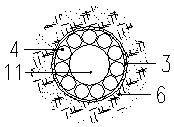

[0031] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0032] In this embodiment, the pile diameter, pile length and layout of the prefabricated piles are determined by the specific design, and the pile types are divided into friction end-bearing piles and end-bearing friction piles according to the force characteristics.

[0033] As shown in the figure, D1 is the inner diameter of the outer casing; h1 is the space distance between the ground and the support structure or member (7); h2 is the distance from the ring support plate to the top of the support structure (member).

[0034] In this embodiment, the inner diameter of the outer casing is larger than that of the prefabricated pile, and the gap thereof is 25mm-100mm. The overhead space between the ground and the support is 150mm-1200mm. Prefabricated piles use steel or reinforced concrete with a diameter of 100-1600mm. The outer c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com