Self-pressurized fuel tank used for space propulsion

A technology for space propulsion and fuel tanks, which is applied to the propulsion system devices of aerospace vehicles, equipment for space navigation, and aircraft for space navigation, etc. It can solve problems such as unfavorable temperature control of spacecraft, and achieve simple structure, reliable operation, and weight reduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

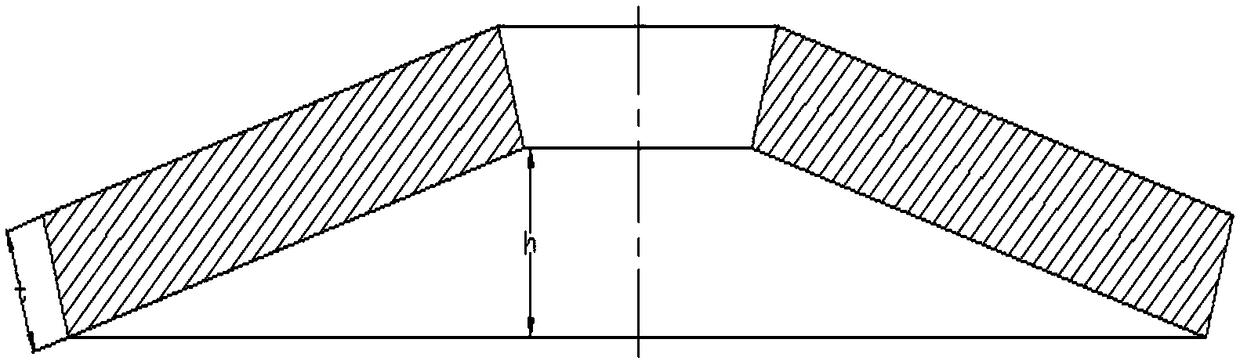

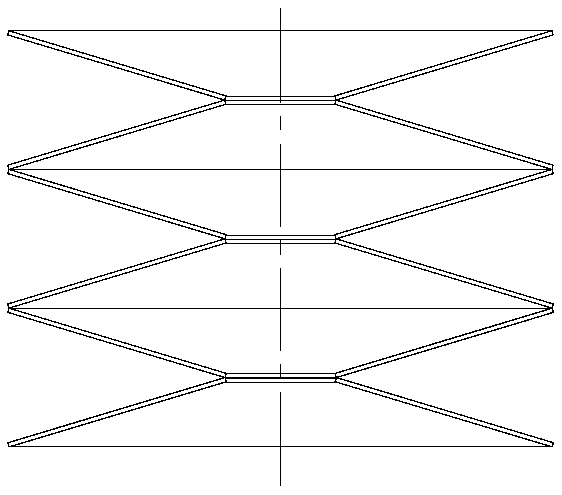

[0040] This embodiment is used for self-pressurized fuel tanks for space propulsion, such as Image 6 As shown, it includes: shell 1, piston 2, upper cover 3, lead screw and nut mechanism 4, motor-bevel gear set 5, disc spring set 6, pipe 7, one end of the shell is externally connected to the pipe, and the other end is connected to the lead screw and nut mechanism , the upper cover 3, the disc spring group 6, and the piston 2 are arranged in sequence from top to bottom inside the housing, the housing located in the lower space of the piston is filled with liquid fuel, and the disc spring group is arranged between the piston and the upper cover, and the disc The upper end of the disc spring group 6 is close to the lower end surface of the upper cover, and the lower end of the disc spring group 6 is close to the bottom surface of the inner wall of the piston 2; a lead screw nut mechanism is connected between the upper cover and the shell, and the lead screw nut mechanism is simul...

Embodiment 2

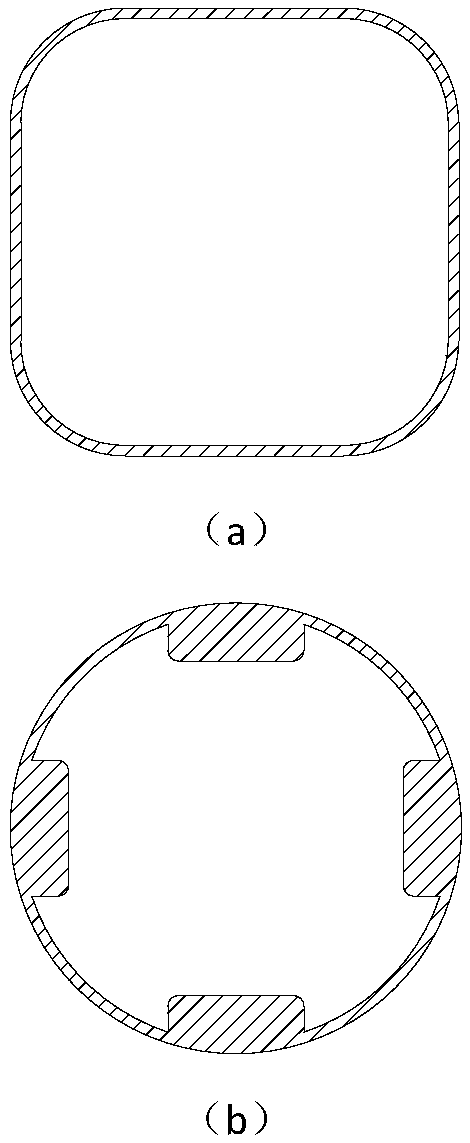

[0045] The motor-bevel gear set of the fuel tank of this embodiment is installed in the loam cake, and the installation method is exactly the same as that in embodiment 1; Difference with embodiment 1 is that piston and loam cake (referring to Figure 9 ). The present embodiment piston (see Figure 10 ) should fit tightly against the non-circular inner wall of the housing, and a circular guide post should be provided on the piston to accommodate the disc spring pack. cover (see Figure 11 ) has a concave circular sleeve set on the circular guide post of the piston, and the upper edge of the upper cover should also be close to the non-circular inner wall of the shell. The outer diameter of the concave circular sleeve is greater than the radius of the disc spring.

Embodiment 3

[0047] The present embodiment fuel tank (referring to Figure 12 ) The motor-bevel gear set is installed in the upper cover, and the installation method is exactly the same as in Embodiment 2; the installation method and function of the screw nut are also exactly the same as in Embodiment 2. piston (see Figure 13 ) will be close to the non-circular inner wall of the shell, the piston is concave, and the piston must have a circular guide post simultaneously, and a disc spring group is installed on the circular guide post. cover (see Figure 14 ) has a concave circular sleeve to be enclosed within on the circular guide post of the piston, and the difference with embodiment 2 is that the upper edge of the loam cake will be close to the concave inner wall of the piston. The outer diameter of the concave circular sleeve is greater than the radius of the disc spring.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com