Extrusion compound device and technology for high-peeling-strength glue-free composite material

A composite material and extrusion compounding technology, which is applied in lamination devices, lamination auxiliary operations, lamination, etc., can solve the problems of difficult control of temperature stability, elevated die temperature, difficulty in film formation and even burning. , to achieve the effect of increasing the activation reaction rate, increasing the mechanical interlocking force, and increasing the degree of activation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

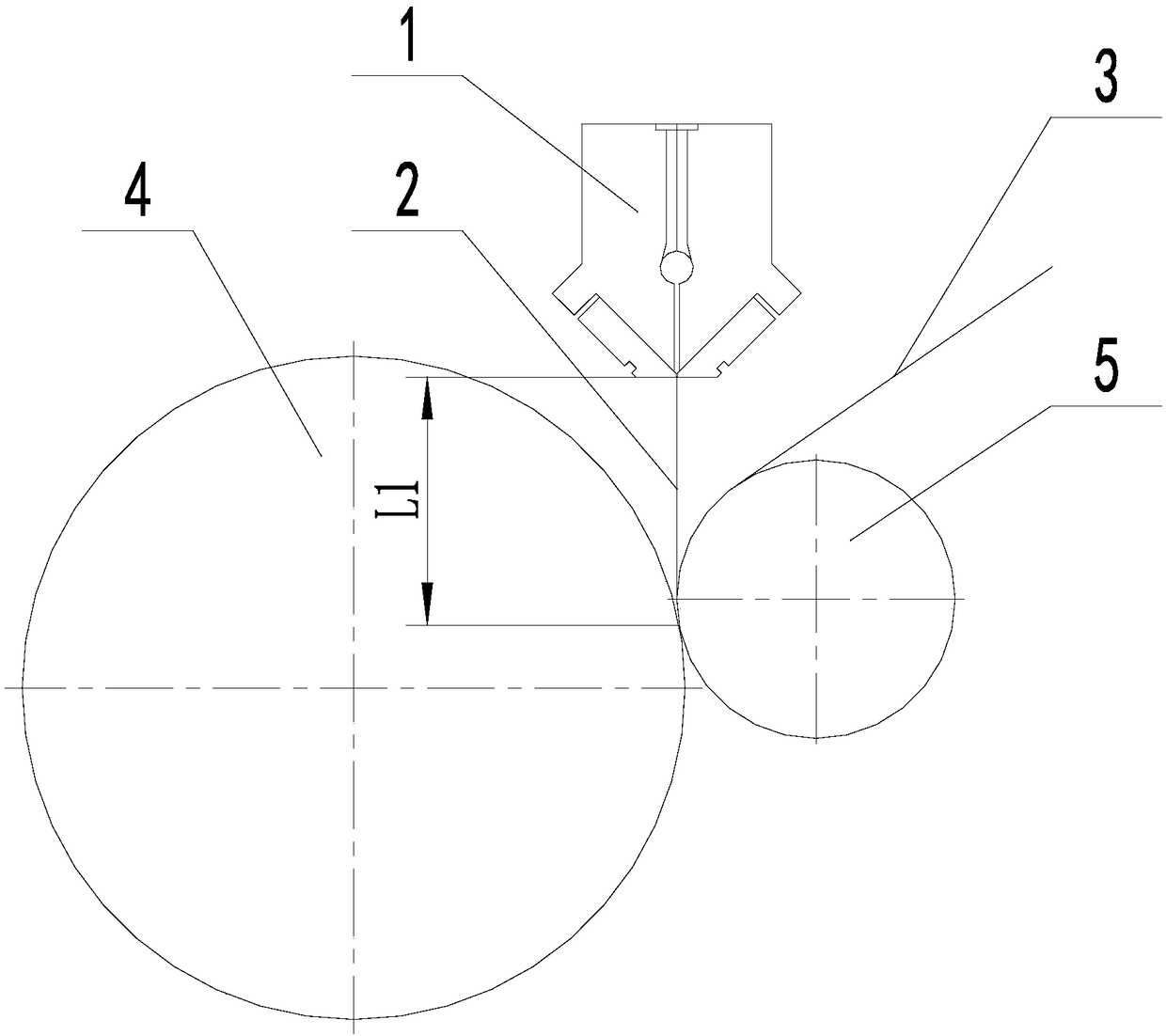

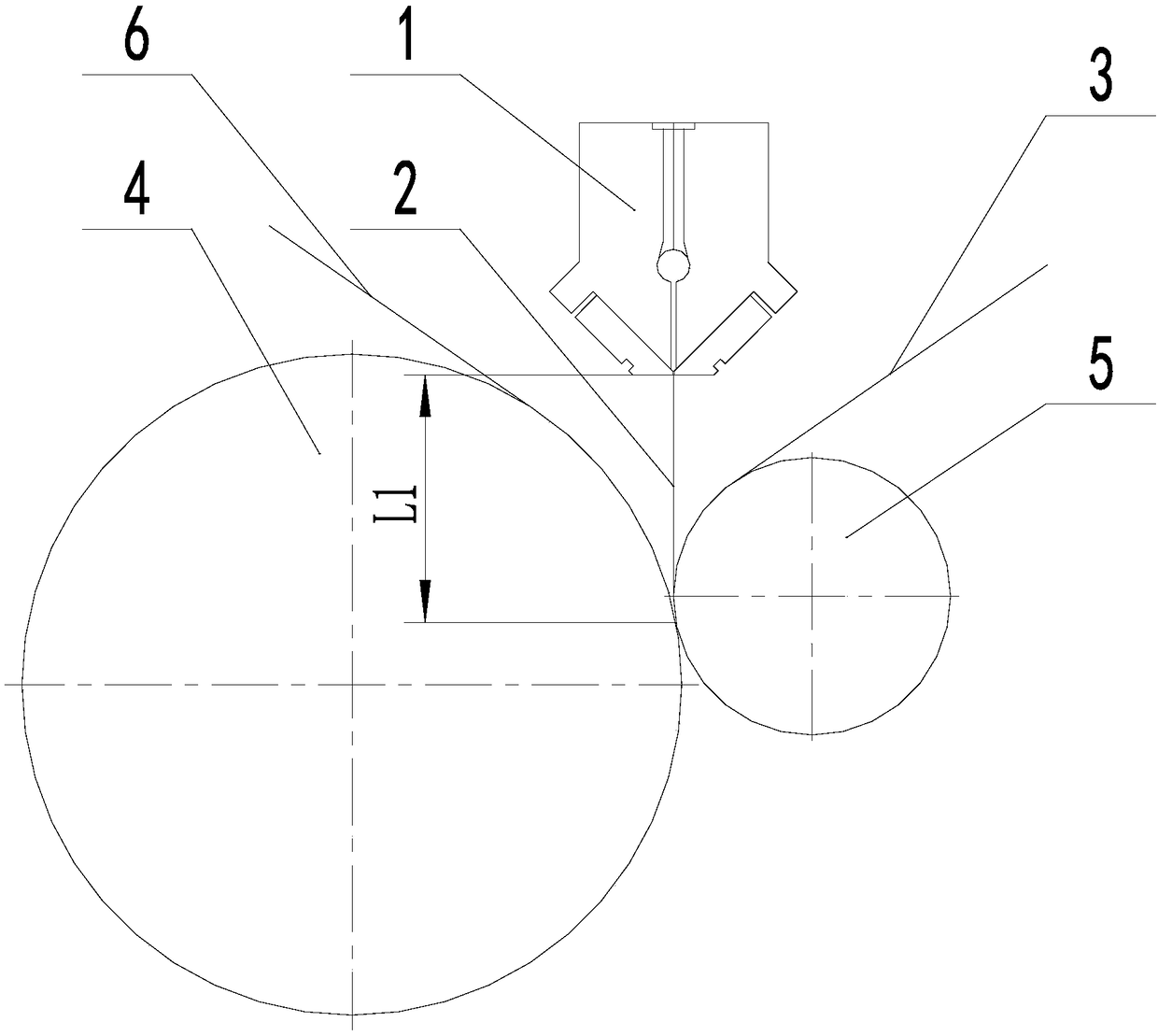

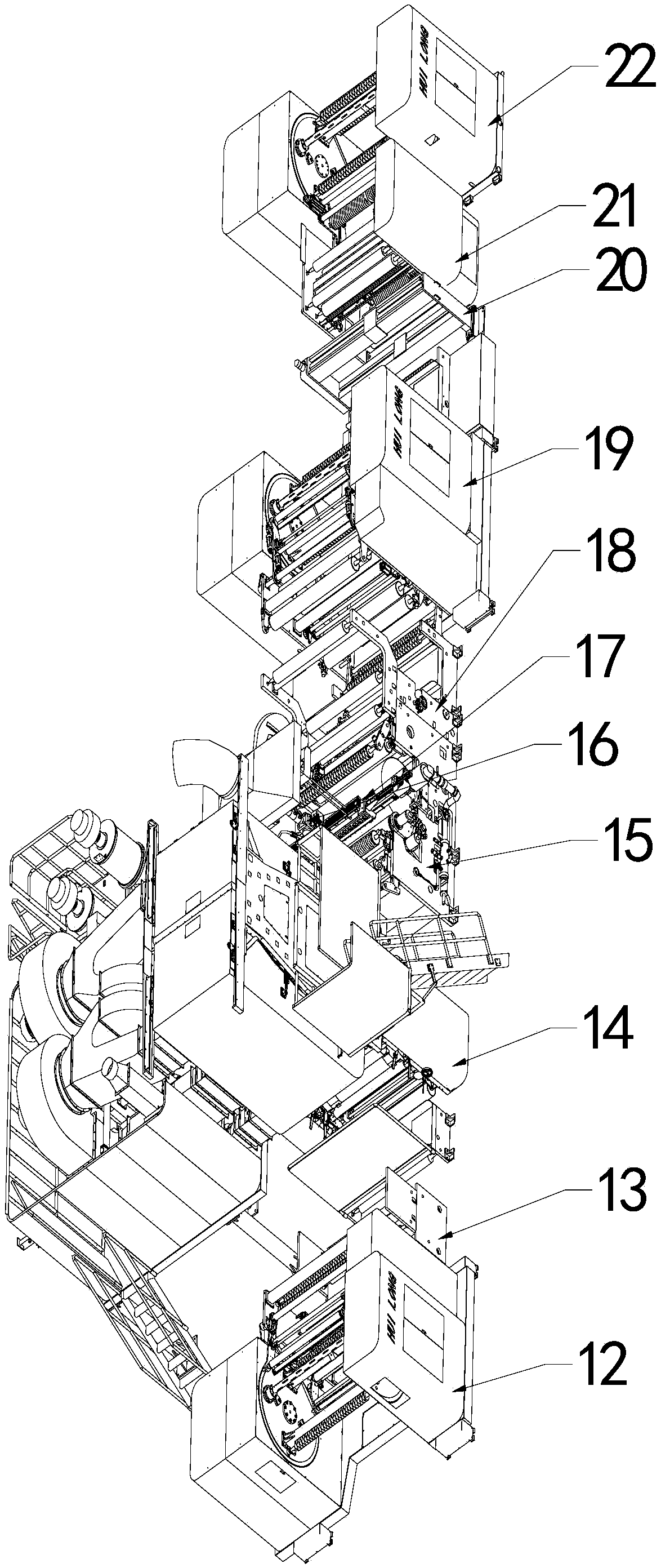

[0057] A kind of extruding composite equipment of high peel strength glue-free composite material in this embodiment, such as image 3 As shown, it includes a substrate unwinding device 12, a polarization treatment device 13, a composite device 15, a winding device 22, a co-extrusion extruder 16 and a carrier energy guide device 17, a substrate unwinding device, a polarization treatment device, The composite device and the winding device are arranged in sequence along the conveying direction of the substrate, the co-extrusion extruder is arranged above the composite device, a composite area is formed in the composite device, and an activation area H is formed between the die of the co-extrusion extruder and the composite device. The activation area is located above the composite area, and a carrier energy guide device is installed in the activation area; the base material released by the base material unwinding device (that is, the main unwinding base material 3) is first subje...

Embodiment 2

[0079] This embodiment is an extrusion lamination equipment for high peel strength glue-free composite materials. Compared with Embodiment 1, the difference is that an oven 14 is also provided between the polarization treatment device and the lamination device. Among them, whether the oven is started to use can be selected according to the actual needs of the prepared composite material. In addition, along the conveying direction of the base material, glue rollers can also be installed in front of the oven, so that this equipment can be used not only in the production of composite materials without glue, but also in the production of composite materials with glue. The user can choose according to the production needs. Thereby making this equipment use wider.

Embodiment 3

[0081] A kind of extruding composite equipment of high peel strength glue-free composite material in this embodiment, such as image 3 As shown, compared with Embodiment 1, the difference is that an oven 14 is also provided between the polarization treatment device and the recombination device. Among them, whether the oven is started to use can be selected according to the actual needs of the prepared composite material. Along the conveying direction of the substrate, glue rollers can also be installed in front of the oven, so that this equipment can be used not only in the production of composite materials without glue, but also in the production of composite materials with glue. The user can choose according to the production needs, so that This device is used in a wider range.

[0082] The extrusion compounding equipment also includes an interlayer unwinding device 19. The interlayer unwinding device releases the interlayer material and sends it to the compound device, whe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com