Denitration catalyst and preparation method thereof

A denitrification catalyst, nitric acid technology, applied in the direction of catalyst activation/preparation, chemical instruments and methods, heterogeneous catalyst chemical elements, etc., can solve the problems of catalyst active site blockage, environmental and human hazards, equipment corrosion, etc., to improve the reaction Activity and stability, accelerated reaction speed, enhanced adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

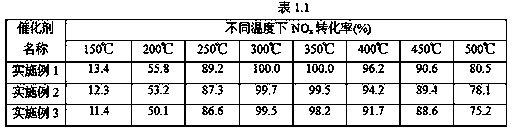

Examples

Embodiment 1

[0023] (1) Purification of halloysite nanotubes

[0024] Weigh 20g of halloysite nanotubes and add them to 100mL of ionized water, stir at room temperature for 30min at a rate of 700rpm, then dropwise add a certain amount of nitric acid to adjust the pH value of the solution to 3.9 and continue to stir for 1h, To remove surface and internal impurities, the mixture was filtered and washed until neutral, dried at 110°C for 12 hours, and finally roasted at 500°C for 5 hours.

[0025] (2) Surface modification of halloysite nanotubes Add purified halloysite nanotubes to deionized water, then add cerium nitrate, urea

[0026] and CTAB were stirred at room temperature for 30 min, then transferred to 90 ° C for 12 h, and then cooled to room temperature. After the product was filtered and washed, it was dried at 110 °C for 12 h, and finally calcined at 500 °C for 5 h to obtain the mesoporous CeO 2 Modified halloysite nanotubes. The mass volume ratio of halloysite nanotubes to deioni...

Embodiment 2

[0030] (1) Purification of halloysite nanotubes

[0031] Weigh 20g of halloysite nanotubes into 200mL deionized water, stir at room temperature for 30min at a rate of 700rpm, then drop a certain amount of nitric acid to adjust the pH of the solution to 4.2 and continue to stir for 1h to Remove surface and internal impurities, then filter the mixture and wash until neutral, dry at 110°C for 12 hours, and finally bake at 500°C for 5 hours.

[0032] (2) Surface modification of halloysite nanotubes Add the purified halloysite nanotubes to deionized water, then add cerium sulfate, urea

[0033]and CTAB were stirred at room temperature for 30 min, then transferred to 90 ° C for 12 h, and then cooled to room temperature. After the product was filtered and washed, it was dried at 110 °C for 12 h, and finally calcined at 500 °C for 5 h to obtain the mesoporous CeO 2 Modified halloysite nanotubes. The mass volume ratio of halloysite nanotubes to deionized water is 1:10, the mass rati...

Embodiment 3

[0037] (1) Purification of halloysite nanotubes

[0038] Weigh 20g of halloysite nanotubes and add them to 150mL deionized water, stir at room temperature for 30min at a rate of 700rpm, then drop a certain amount of nitric acid to adjust the pH of the solution to make it reach 4 and continue to stir for 1h to Remove surface and internal impurities, then filter the mixture and wash until neutral, dry at 110°C for 12 hours, and finally bake at 500°C for 5 hours. During this process, the mass volume ratio of halloysite nanotubes to deionized water was 1:7.5.

[0039] (2) Surface modification of halloysite nanotubes Add purified halloysite nanotubes to deionized water, then add cerium nitrate, urea

[0040] and CTAB were stirred at room temperature for 30 min, then transferred to 90 ° C for 12 h, and then cooled to room temperature. After the product was filtered and washed, it was dried at 110 °C for 12 h, and finally calcined at 500 °C for 5 h to obtain the mesoporous CeO 2 M...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com