High-power thyristor type traction rectifier and braking inverter bidirectional conversion system, and control method

A bidirectional converter and thyristor technology, which is applied in the direction of electric braking system, AC power input conversion to DC power output, output power conversion device, etc., can solve the problem of not filtering out harmonics well and large reactor inductance , unreliability and other problems, to achieve the effect of simple control scheme, strong short-circuit capability, and elimination of harmonics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Embodiments of the invention are described in detail below, examples of which are illustrated in the accompanying drawings. The embodiments described below by referring to the figures are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

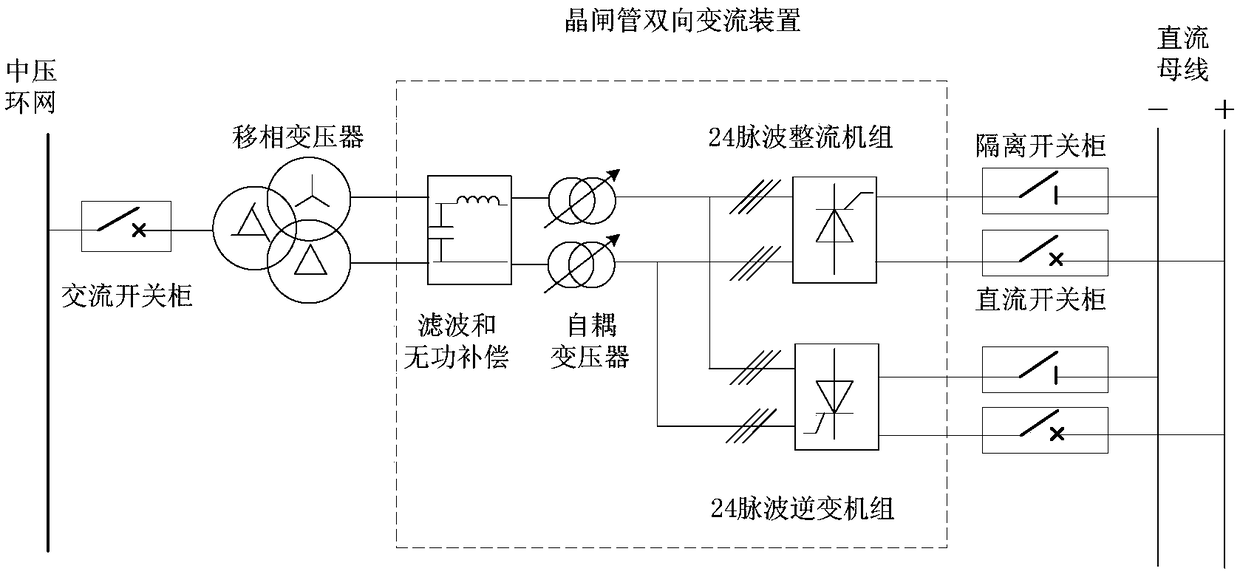

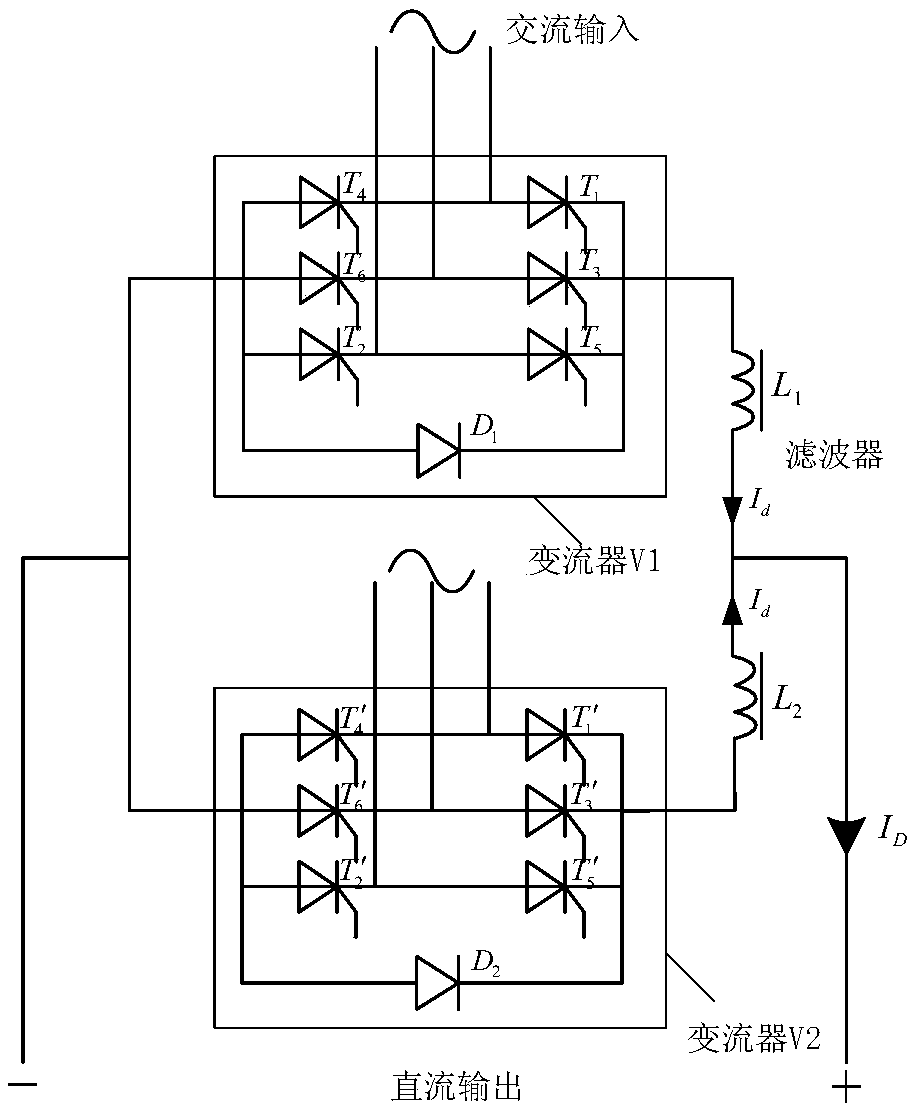

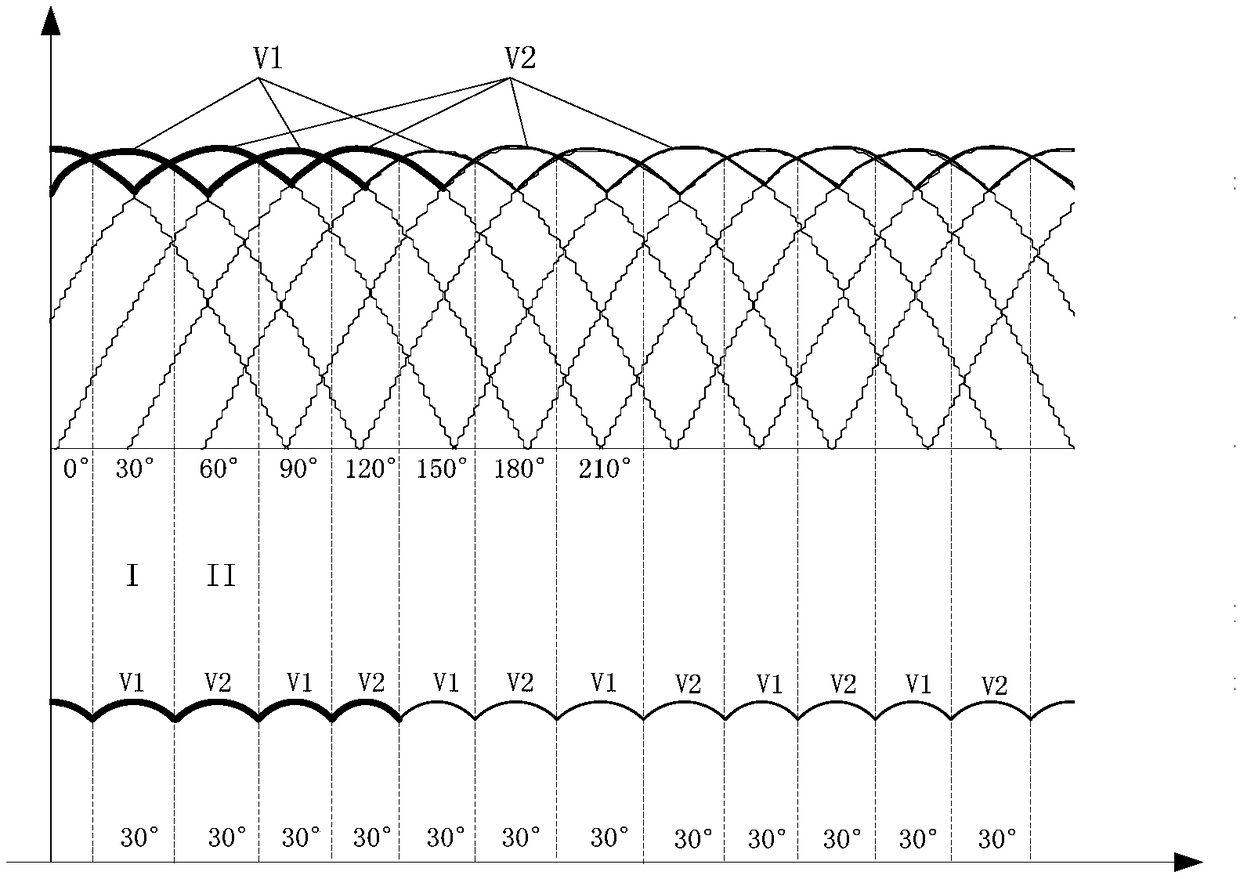

[0025] Such as figure 1 As shown, the high-power thyristor-type traction rectification, braking, inverter, and bidirectional conversion system is mainly composed of AC switchgear, phase-shifting transformer, thyristor bidirectional converter, DC switchgear, and negative isolation switchgear. Thyristor bidirectional conversion system has two purposes of rectification and inverter, which can feed back the braking energy of the train to the medium-voltage AC grid to achieve energy saving, and can also transmit the AC grid to the DC bus to provide electric energy for train traction and stabilize DC. The busbar voltage, using its own overload capacity, can temporarily replac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com