A multi-station detection and assembly equipment for stator assembly and housing

An assembly equipment and multi-station technology, applied in the direction of electromechanical devices, electric components, stator/rotor body manufacturing, etc., can solve the problems of no equipment, etc., achieve high work efficiency, improve work efficiency, and good practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

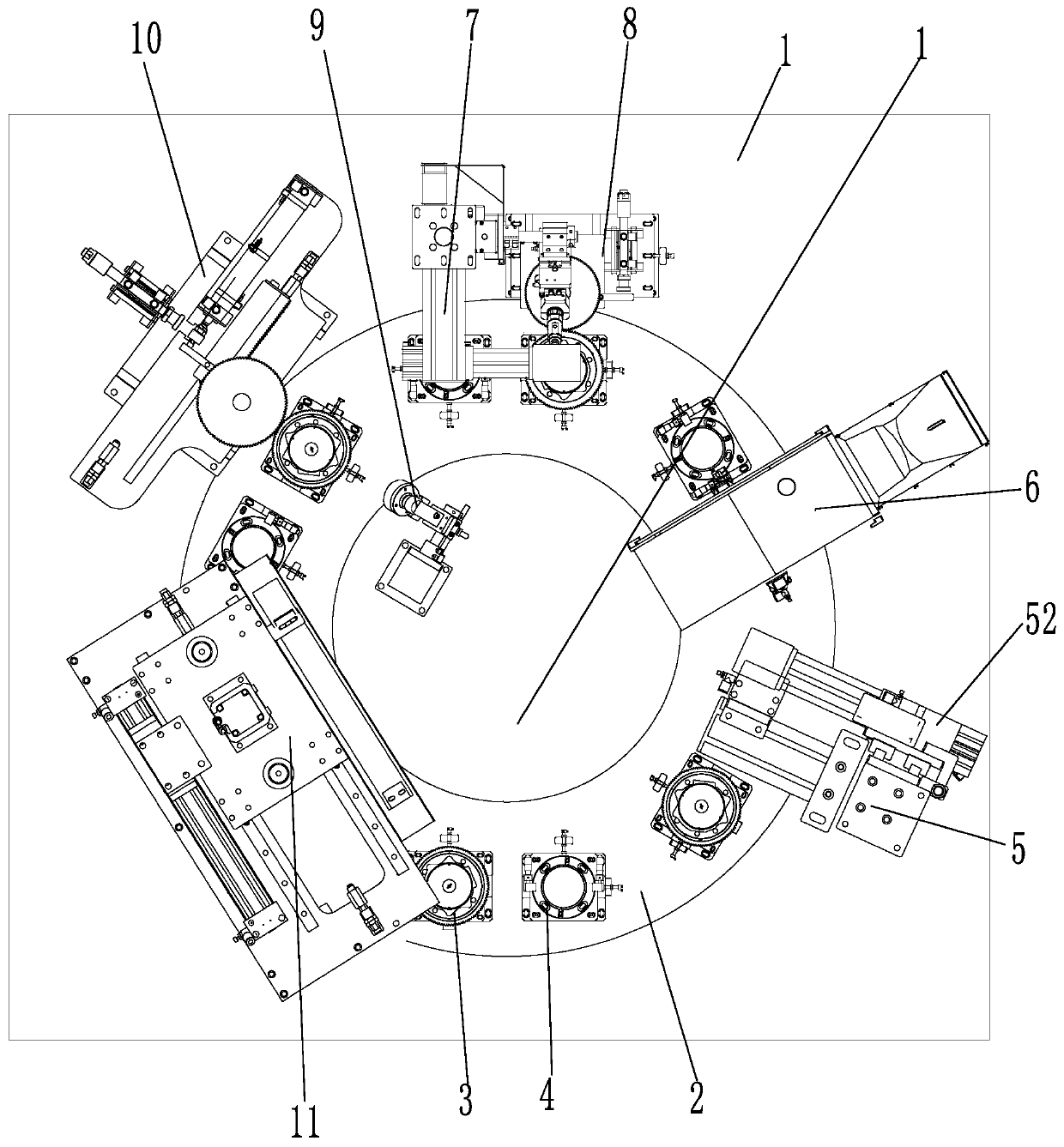

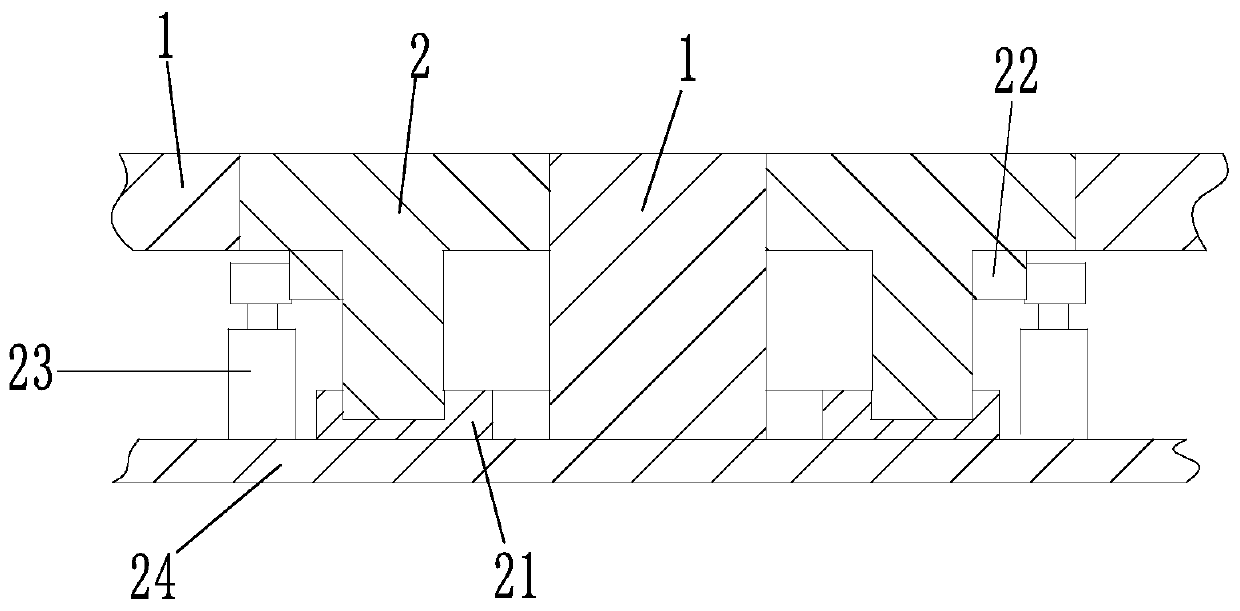

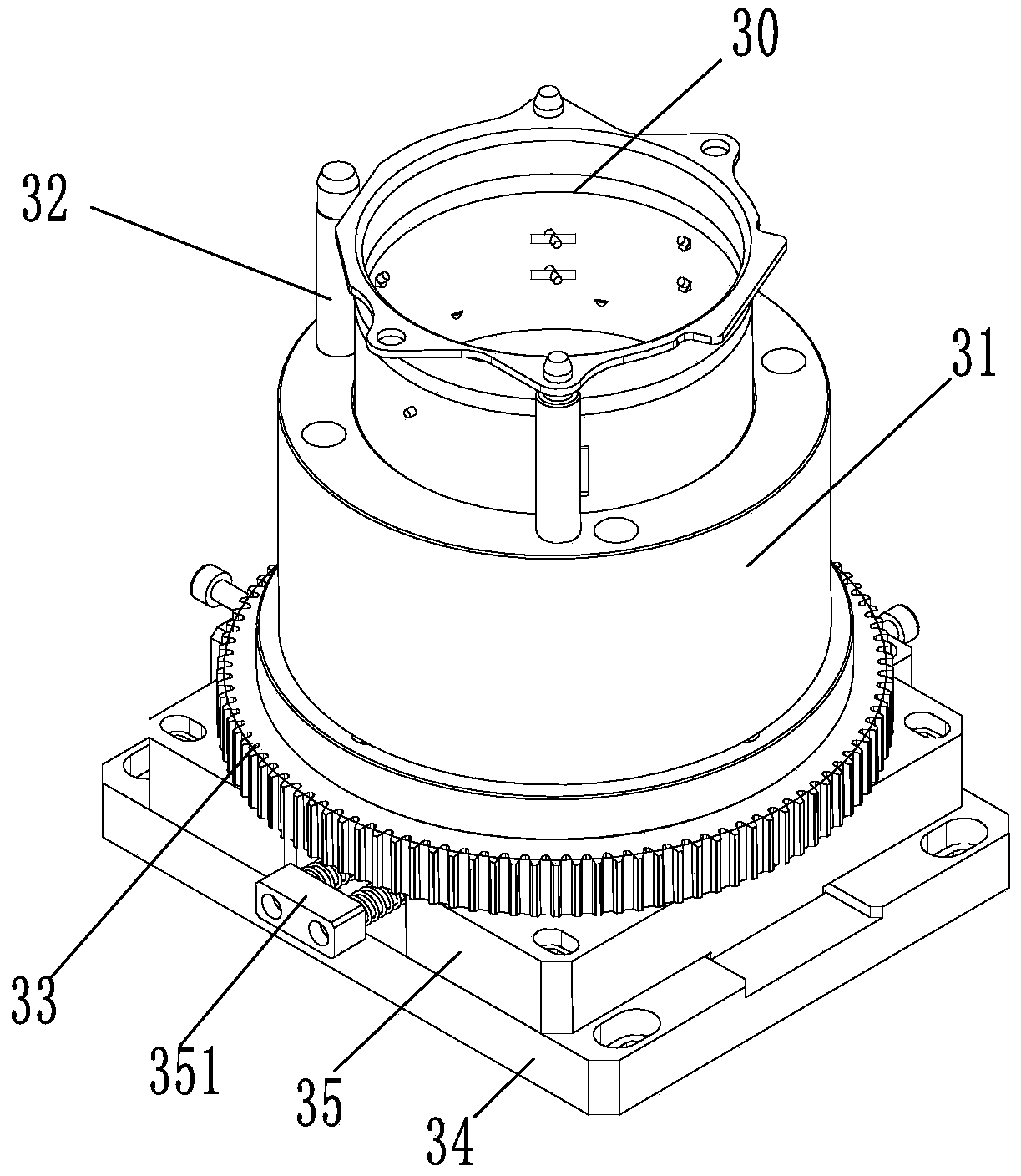

[0037] Figure 1 to Figure 15 Among them, a multi-station detection and assembly equipment for stator assemblies and casings, including a workbench 1 and a turntable 2 located on the upper side of the workbench 1, the turntable 2 is circular, and the parts inside the circular turntable 2 and The position of the workbench 1 is fixed, and the turntable 2 can rotate around the axis of the disc relative to the workbench 1. The lower side of the turntable 2 is provided with an annular track 21, and the outer side of the turntable 2 is provided with rotating teeth 22 above the annular track 21. The lower side of the turntable 2 is provided with six transmission motors 23 with gears. Outer equidistant arrangement, the gear of transmission motor 23 and the tooth form engagement of turntable 2, drive turntable 2 to rotate by six transmission motors 23,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com