A kind of pressure sensor quality detection equipment

A pressure sensor and detection equipment technology, which is applied in the calibration/testing of force/torque/power measuring instruments, measuring fluid pressure, instruments, etc., can solve the problems of low detection accuracy of small sensors, product damage, large impact, etc., to achieve The effect of simple structure, accurate measurement results and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

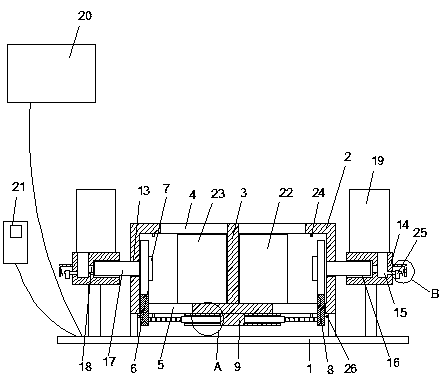

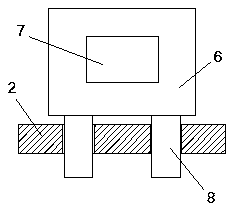

[0030] see Figure 1 to Figure 4 , the present invention provides a quality testing device for pressure sensors, comprising a base 1, a standard part 22 and a test part 23, a detection box 2 is arranged at the center of the top of the base 1, and a partition 3 is arranged at the center of the inside of the test box 2, The partition 3 divides the interior of the detection box 2 into two detection cavities on the left and right. The tops of the two detection cavities are provided with placement ports 4, and the bottom ends of the two detection cavities are provided with chutes 5. The inside of the chute 5 Slidingly connected with a slide bar 8, the top of the slide bar 8 is provided with a push plate 6, and the bottom end of the slide bar 8 extends to the outside through the chute 5;

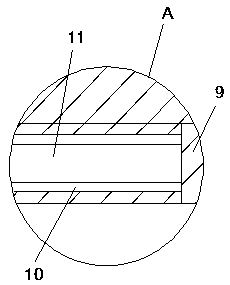

[0031] The side wall of the push plate 6 is provided with a touch block 7, the bottom end of the detection box 2 is provided with a driving chamber 9, and the left and right ends of the driving ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com