Electric heating furnace automatic feeder capable of intermittently feeding and discharging and using method of electric heating furnace automatic feeder

An electric heating furnace and automatic feeding technology, which is applied in lighting and heating equipment, furnace, electric charge control, etc., can solve the problem that the heating time of bars is difficult to be unified, so as to avoid inconsistent heating length, increase safety and reduce labor The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to clearly illustrate the technical features of the solution, the solution will be described below through specific implementations.

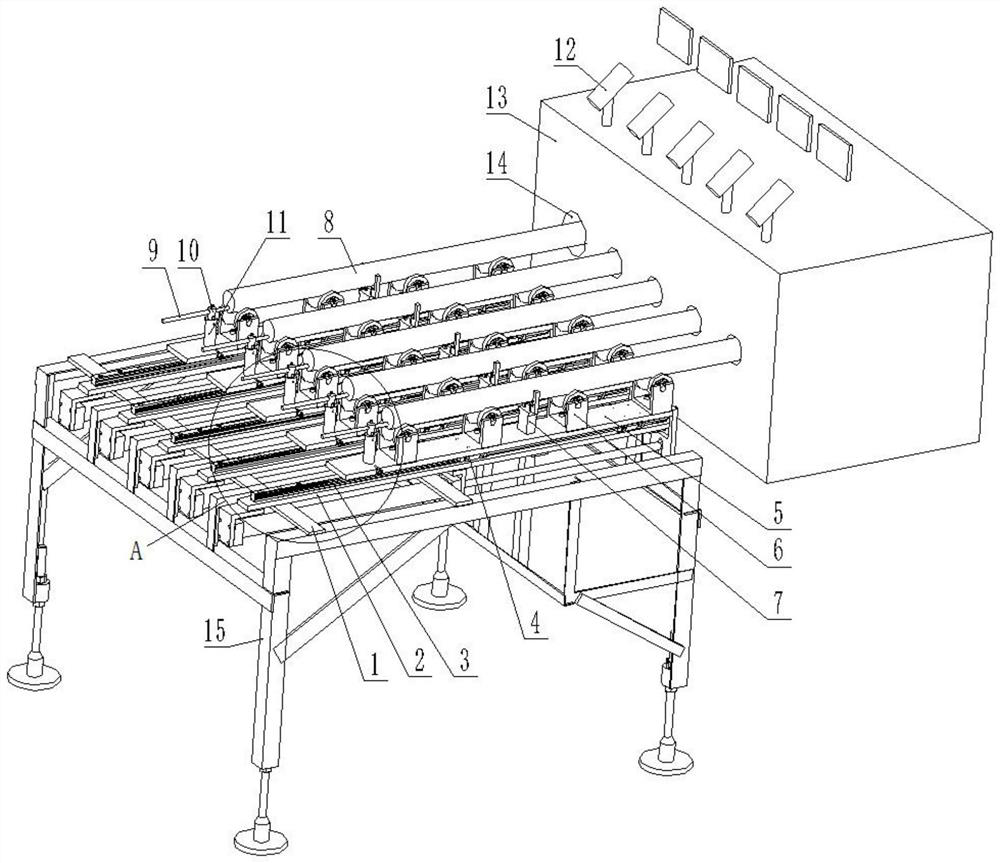

[0032] like Figure 1-6 As shown, the present invention includes a height-adjustable placing rack 15, on which multiple groups of pushing devices are arranged side by side, each group of pushing devices corresponds to a furnace cavity 14 of the electric heating furnace 13, and the placing rack 15 can be adapted to the height adjustment The height of the furnace cavity 14 . Each support leg of the placing rack 15 is threadedly connected to a support rod, and the height can be adjusted by rotating the support rod.

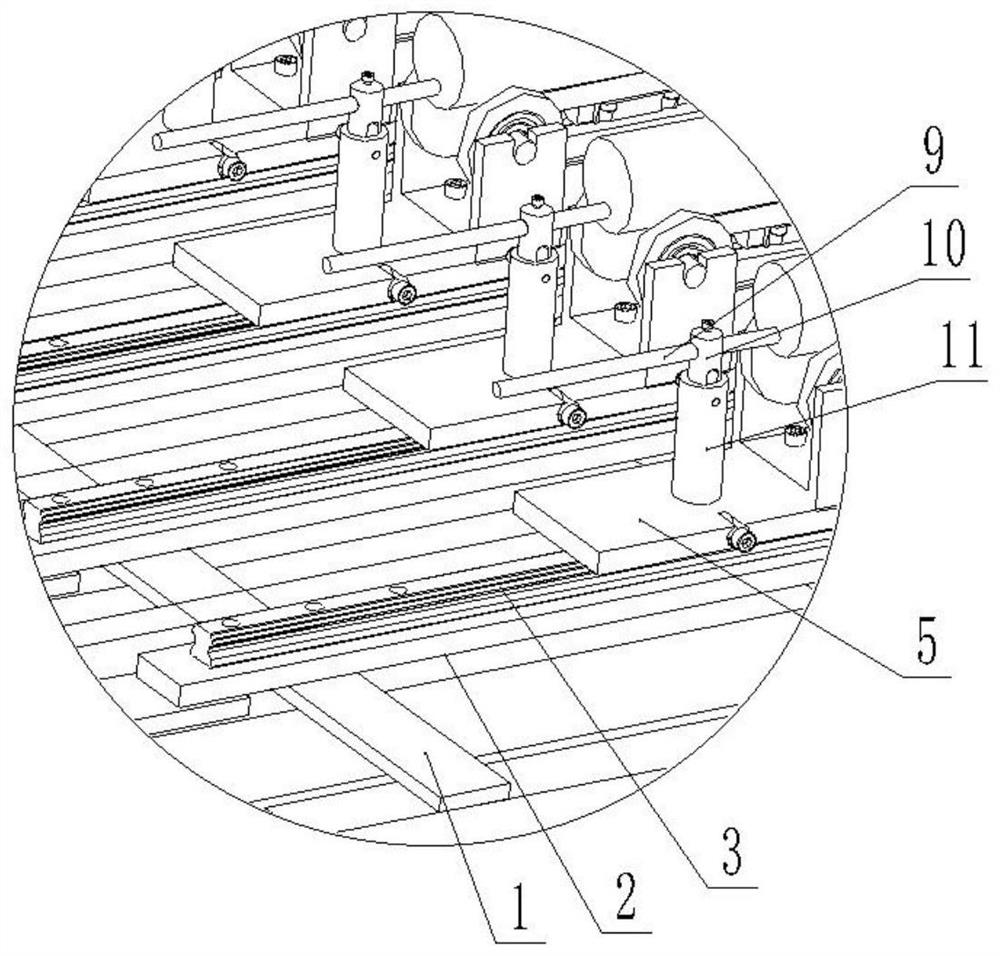

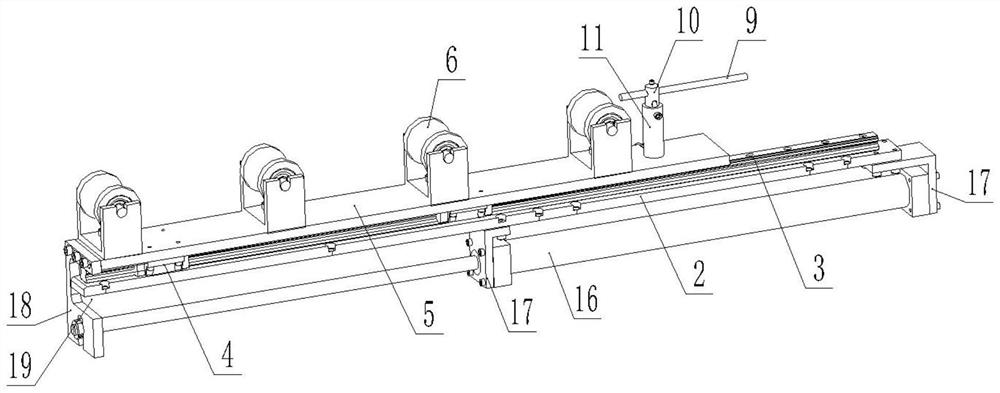

[0033] Several cross braces 1 are connected on the top surface of the placing rack 15 , each group of pushing devices includes a bottom plate 2 that is vertically fixed to each cross brace 1 , the linear guide rails 3 are fixedly installed on the top surface of the bottom plate 2 , and the linear guide rails 3 The sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com