Positioning-clamping plate feeding device

A plate feeding device, positioning and clamping technology, applied in the direction of packaging, transportation and packaging, paper/cardboard containers, etc., can solve the problems of instability and poor applicability, and achieve good effect, prevent rotation, and accurate position Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] List specific embodiments below and further illustrate the specific implementation of the present invention in conjunction with accompanying drawing:

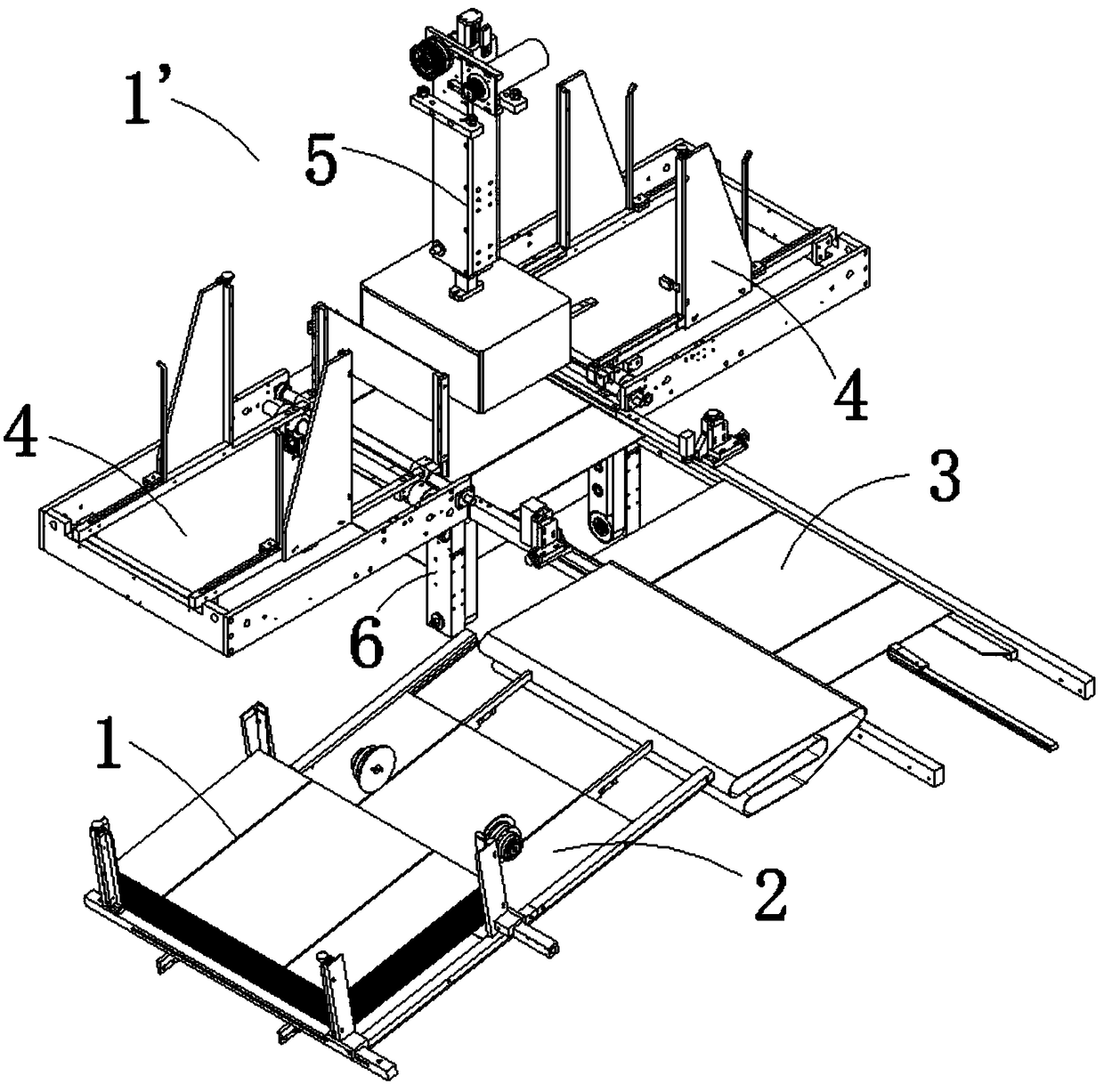

[0045] refer to figure 1 , a box making machine 1', including a silo discharging module 1, a slope glue passing module 2, a guide rail glue spraying module 3, a side plate discharging module 4, a module pressing module 5 and a cavity forming module 6.

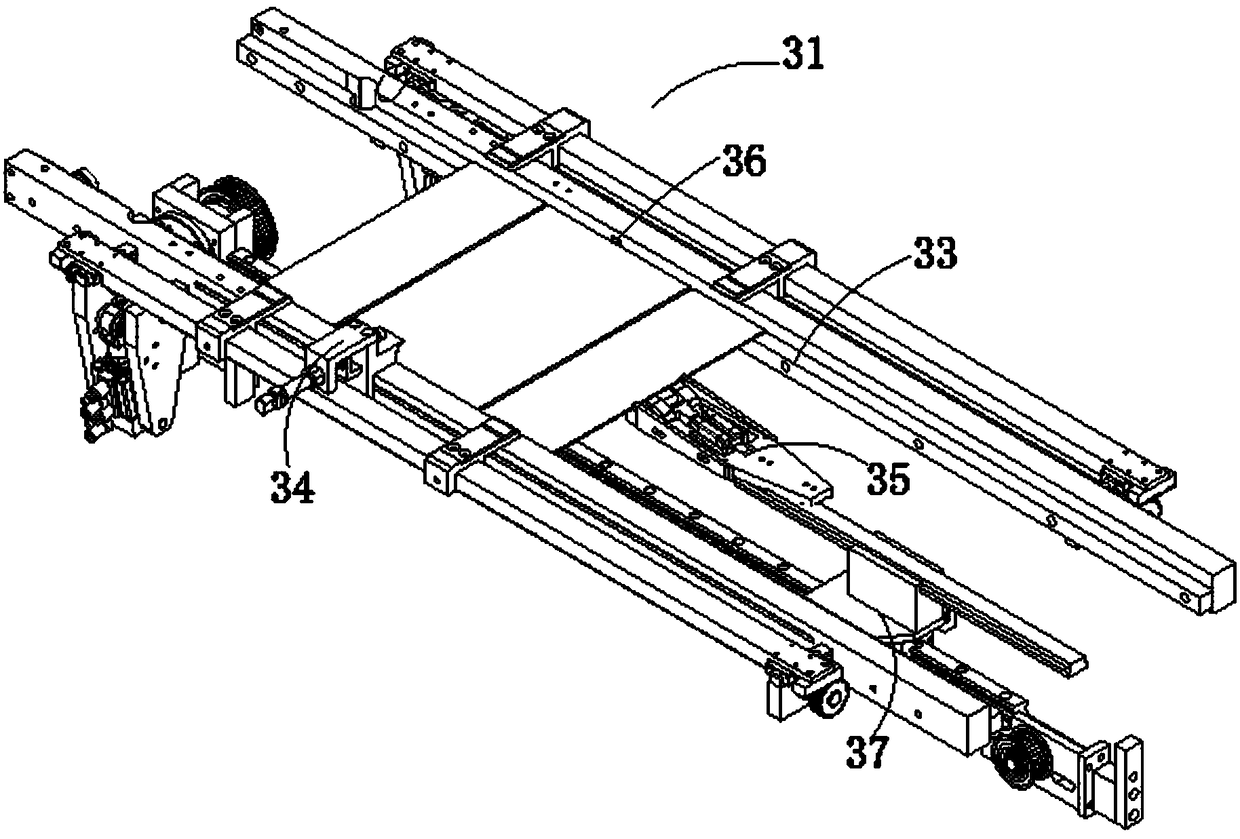

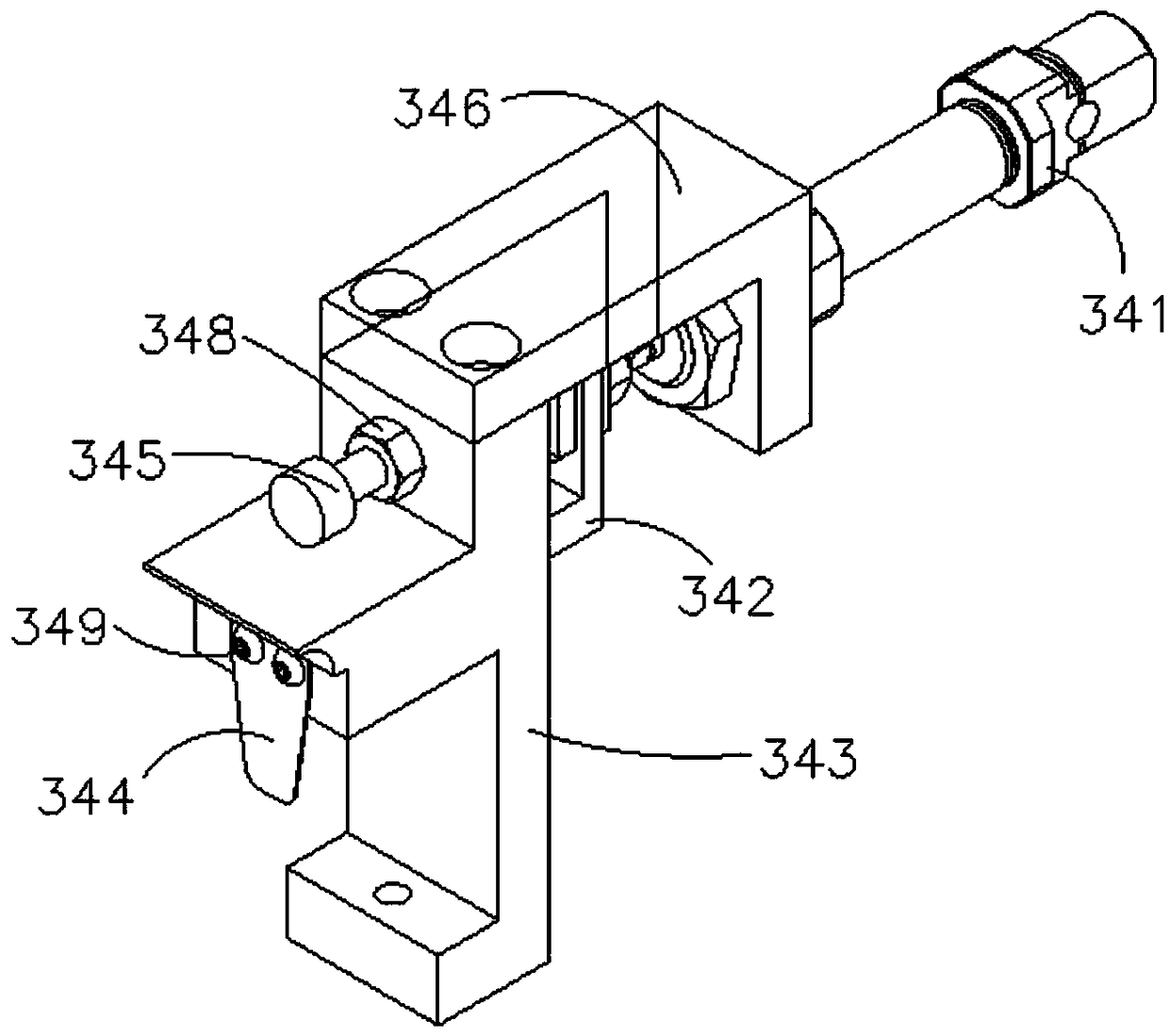

[0046] refer to figure 2 , the guide rail glue spraying module 3, the guide rail glue spraying module 3 includes a positioning clamping board feeding device 31, the positioning clamping board feeding device 31 is used to push the box bottom plate forward, and the positioning clamping board feeding device 31 includes a guide rail 33, a positioning Device 34, head device 35, pad 36 and drive unit 37 are set up on two guide rails 33 relative to pad 36, and positioning device 34 is set up on two guide rails 33 relative to pad 36, and head device 35 pushes away box base plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com