Processing technology of multilayer superimposed biological recognition lens module

A lens module and biometric identification technology, applied in the fields of lenses, optics, instruments, etc., can solve problems such as low efficiency, cover-up of appearance yield rate, and unsatisfactory product size accuracy, and achieve high processing accuracy, novel technology, and high-quality products. The effect of high appearance yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

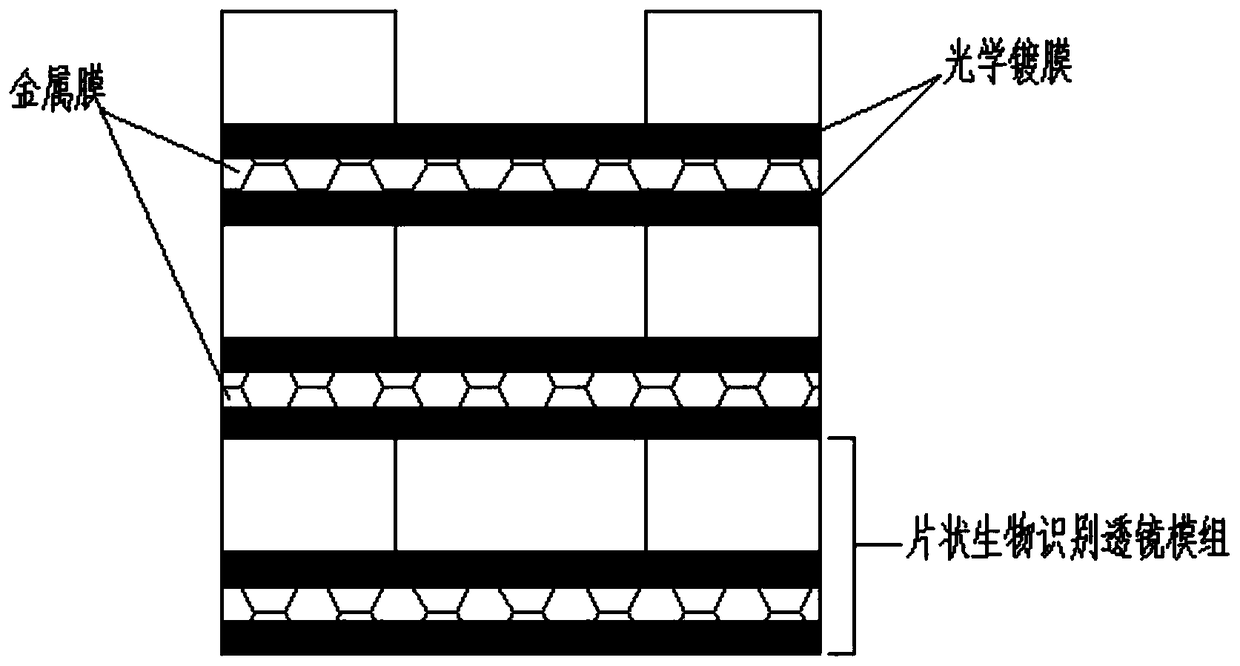

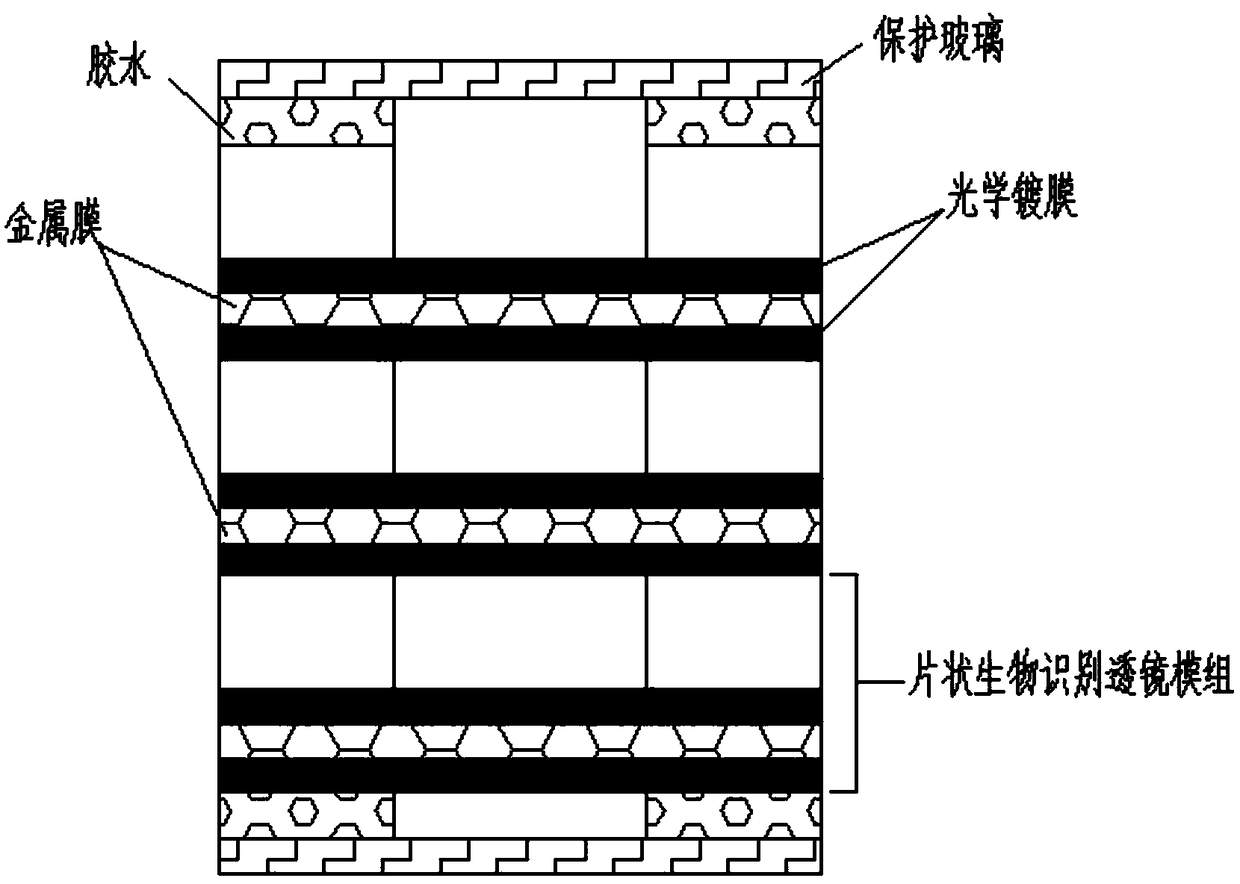

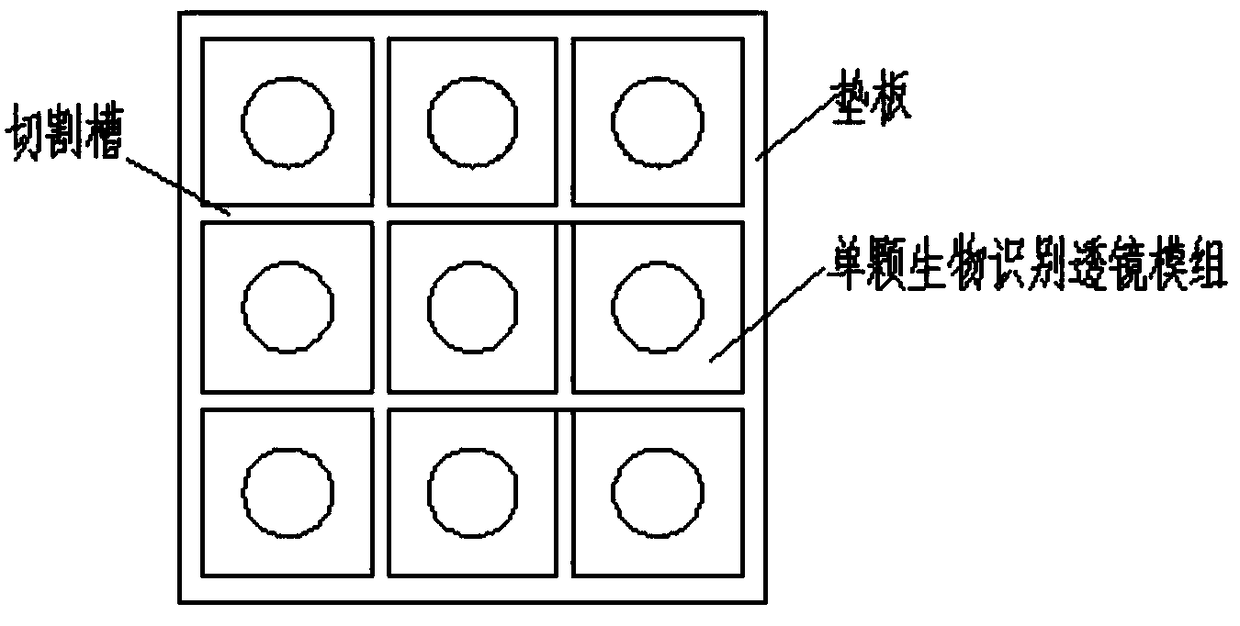

[0024] refer to figure 1 , figure 2 , image 3 with Figure 4 , the processing technology of a kind of multi-layer laminated biometric lens module of the present invention, comprises the following several steps:

[0025] The first step is to superimpose the biometric lens module, and align and stack three layers of the same sheet-shaped biometric lens module;

[0026] The second step is to attach the protective glass, and attach the protective glass to the upper end of the uppermost sheet biometric lens module and the lower end of the lowermost sheet biometric lens module with glue;

[0027] The third step is metal blade cutting. Place the multi-layer sheet biometric lens module after bonding the protective glass in the second step on the backing plate with cutting grooves to carry out the separation between the multi-layer sheet biometric lens module and the cutting groove. Align the CCD between them and use a Disco metal blade to cut the multi-layer sheet biometric lens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com