Lattice type adjustable artificial wave making plate device and method

A wave-making board and adjustable technology, which is applied to measuring devices, instruments, fluid dynamics tests, etc., can solve problems such as reducing manufacturing costs, and achieve the effects of simple and convenient operation, high precision, and reduced labor costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

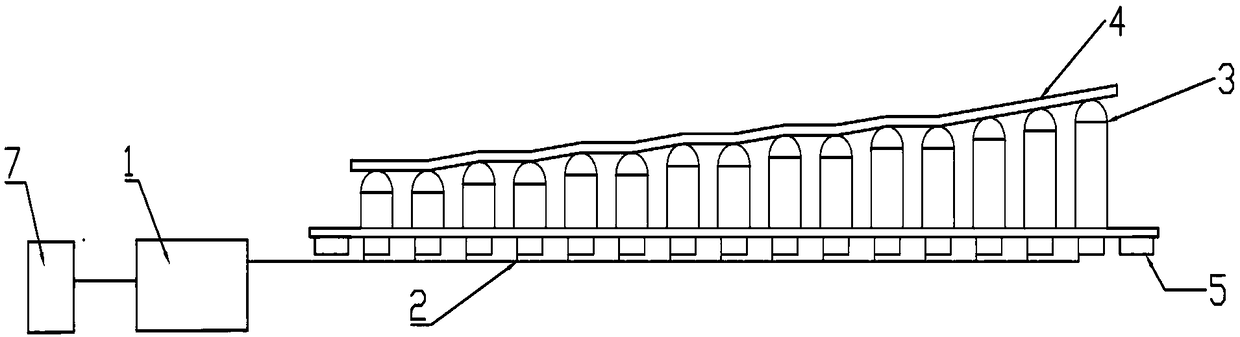

[0030] Such as figure 1 As shown, an artificial wave-making device of the present invention includes a hydraulic pump 1 , a hydraulic pipeline 2 , a hydraulic strut 3 , a wave-making plate facing the water 4 , a support plate 5 , a connecting piece 6 and a hydraulic control system 7 .

[0031] by figure 1 The formation of the shape of the wave-making plate facing the water is taken as an example to illustrate the specific implementation process of the present invention.

[0032] 1. If figure 1 The shape of the wave-making plate facing the water is shown, and the height data of each hydraulic strut is obtained through analysis.

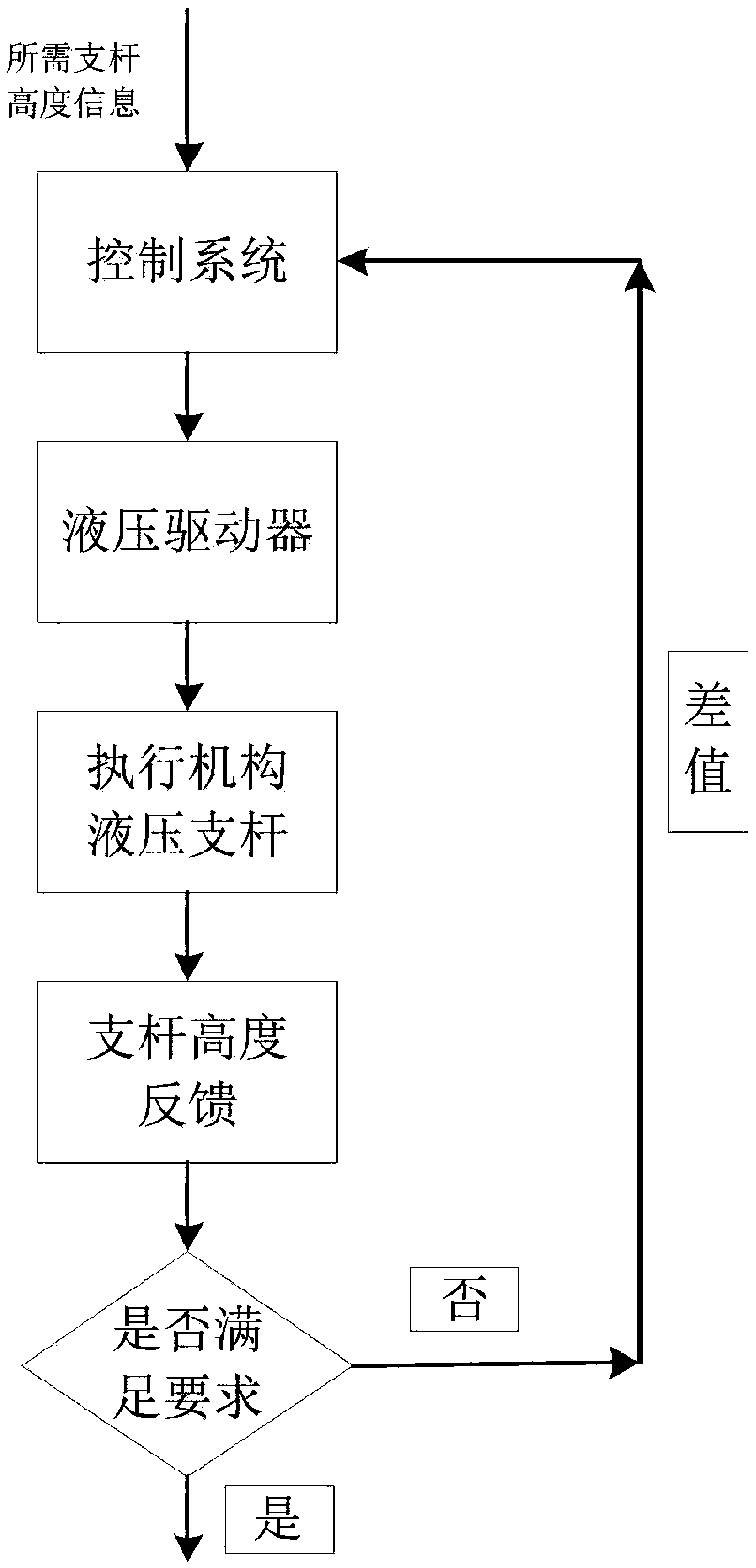

[0033] 2. According to the height data obtained in step 1, the hydraulic pump performs pressure supply to provide pressure support for the height data of the hydraulic strut. The execution process is as follows ima...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com