Environment-friendly heat preservation and shock absorption anti-crack ground system and construction method thereof

A ground system and environment-friendly technology, applied in the direction of elastic floor, insulation layer, etc., can solve the problems of no sound insulation, long construction period, easy cracking and hollowing, etc., achieve excellent thermal insulation and shock absorption effect, facilitate rapid construction, and reduce construction costs. self-respecting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

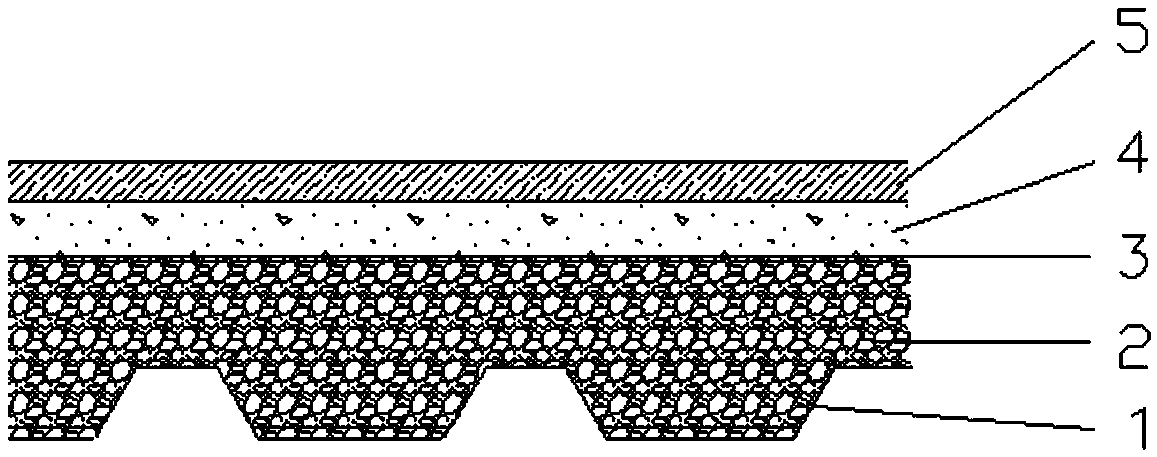

[0041] The ground system of this embodiment is a light steel keel system plus a high-rise building interlayer floor slab thermal insulation and shock absorption ground system.

[0042] The base layer is a profiled steel plate. After the base layer is laid, the overall levelness of the base layer is tested. When the flatness meets the requirements, the dry density of 500 kg / m is laid on the base layer. 3 Modified polystyrene particle lightweight aggregate concrete, the construction thickness is 50mm. After leveling the surface of the modified polystyrene particle lightweight aggregate concrete, press a layer of glass fiber mesh cloth, and close the surface on the glass fiber mesh cloth until the modified polyphenyl particle light aggregate concrete slurry can bond the glass fiber grid cloth. After the strength of the modified polyphenylene particle lightweight aggregate concrete reaches 1.0MPa, lay a super-high-strength non-shrinkage transition mortar layer with a thickness of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com