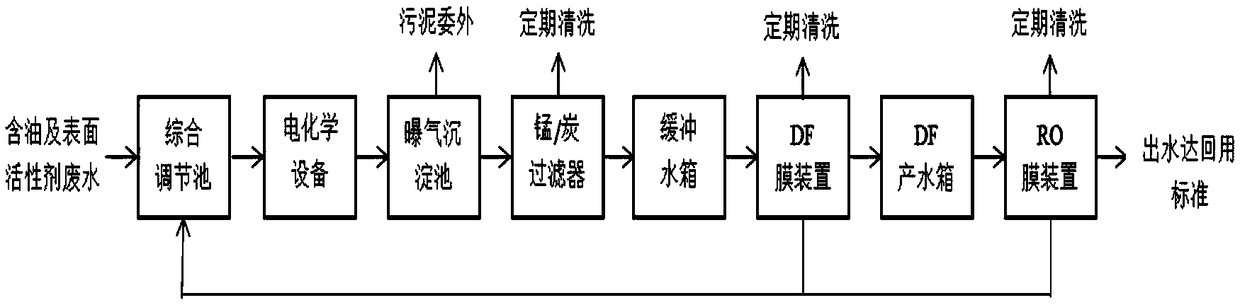

Equipment and technology for recycling wastewater containing oil and surfactants

A surfactant and wastewater technology, used in water/sewage treatment, water/sewage multi-stage treatment, neutralized water/sewage treatment, etc. Short, small process area, realize the effect of automatic management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The present invention is used for the application of the reusable equipment and process of oily and surfactant wastewater in certain oily and surfactant wastewater:

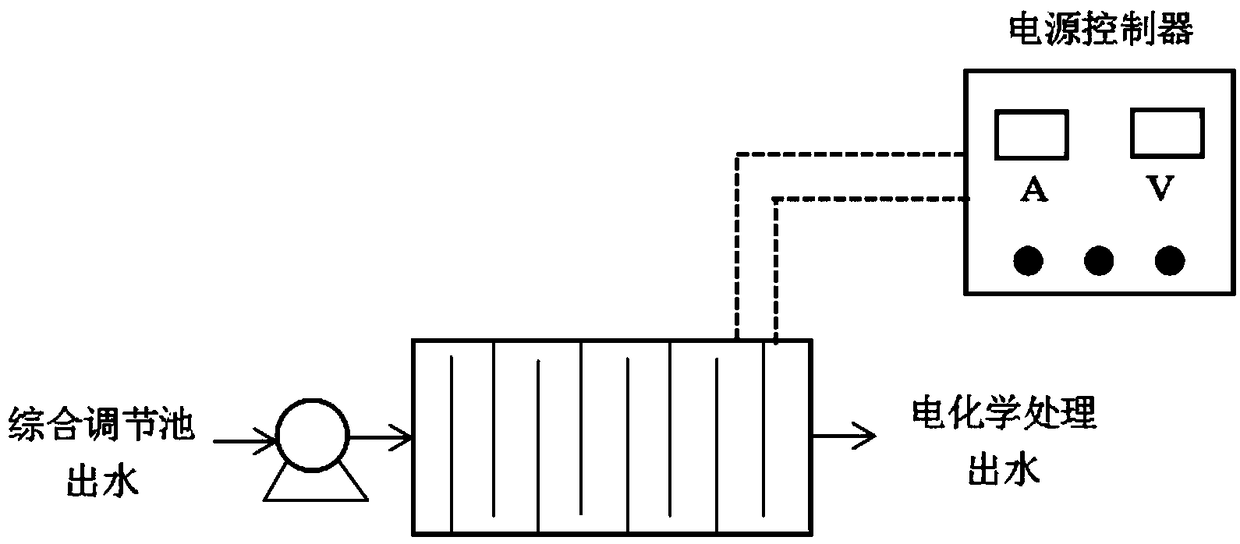

[0044]For the oily and surfactant wastewater of a factory whose initial influent COD≦60mg / L, the pH is adjusted to 5.0-6.0 with dilute sulfuric acid in the comprehensive adjustment tank, and the conductivity is adjusted to 7000-9000μs / cm with NaCl; the adjusted wastewater is passed through The lift pump enters the electrochemical treatment equipment, and the flow rate is set at 0.5-0.8m 3 / h, the DC current is controlled to be 1.0-2.0A, the voltage is 50-70V, the effluent is introduced into the aeration sedimentation tank, the aeration rate is controlled to be 80-100min / L, the pH is adjusted to 9.0-10.0 with NaOH, and the residence time of the sedimentation tank It takes 10-20 minutes to complete the solid-liquid separation. The clear liquid is first filtered through the manganese sand filter through the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com